I am looking for feedback on a brewstand I am thinking of building.

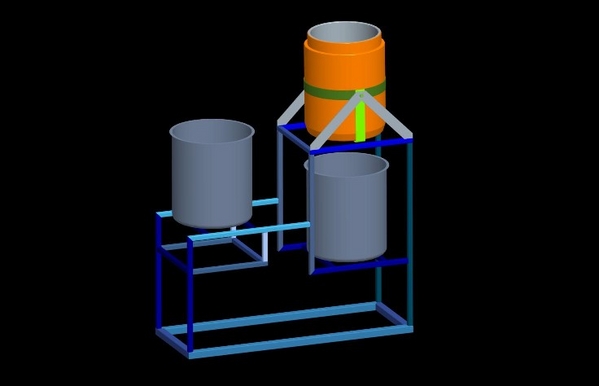

First a diagram of the layout.

http://www.pbase.com/me2001/image/71581680

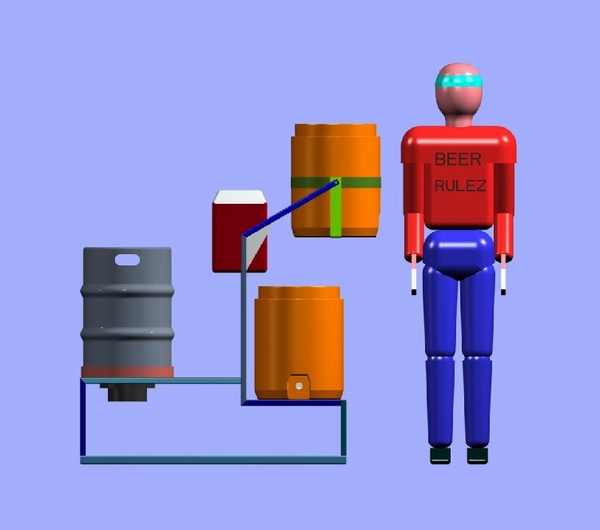

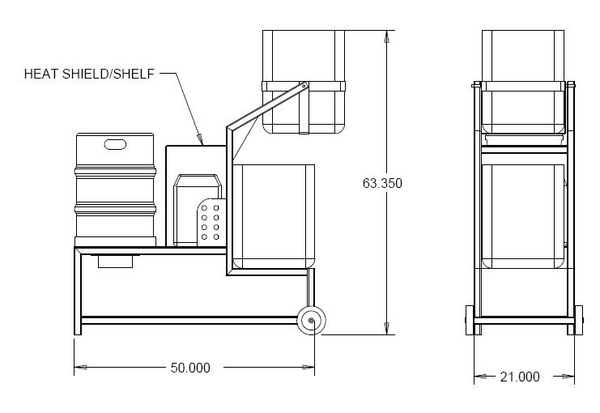

Its a clone of a More Beer 1550.

http://morebeer.com/product.html?product_id=15198

I have a HERMS unit now, but I need to change the mash setup and I don't like my stand. I want something compact and yet nice to use. I don't want to be dragging out kettles and stands and pumps every time I want to brew something. I want to roll out one stand, plug it in and start brewing.

I already have most of the pieces to build this design.

My new design is a HERMS design but instead of putting the heat exchange coil in the hot water tank, it goes in its own heating tank. For now I have that being a corny keg, but I might change that. I'd like something a bit smaller. The heating tank is stirred via a pump so that the heat exchange between the water and the wort coil is good.

Here is another system designed like this.

http://home.comcast.net/~verhulst/RIMS/

My heater tank and hot water tank will each have a computer controlled 4.5KW electric element. The whole heating system is controlled via laptop linked to the controls box by an RS232 cable. The pump speed is manually controlled by a dimmer switch.

There will be electronic temperature sensors in the mash vessel, the hot water tank and the heater tank. Temps will be displayed and plotted on the laptop.

The mash vessel is a 10 gallon Gott with a false bottom. It tips for easy emptying. The boiling kettle and hot water kettle are 15.5 gallon Sanke kegs. I want to be able to brew enough wort to fill 2 6 gallon carboys.

There will be no hard plumbed lines. No electronic control valves. All inlets/outlets will have quick connects. To change the flow, a few pieces of hose with QCs will be moved.

The only burner is under the boiling kettle. I didn't put a propane tank on the stand because I didn't want it near the burner heat and someday I'll probably connect this to natural gas and then I won't need a propane tank.

All the tanks will have level gauges.

I want it to be easy to clean after brewing. I am wondering how I will get the boiling kettle and hot water kettle totally empty when I am done brewing. Unplug them and turn them upside down ?

How does one dry the inside of hoses ? I am thinking of using an air hose to blow out the counter flow chiller after its been flushed. I am still trying to figure out how to get the heat exchange coil empty in the heater vessel.

I might put the valves in the bottom of the hot water tank and the mash vessel, not the side as is traditionally done.

The cart will be about 18 inches wide and nearly 4 feet long. I could make it shorter, but I don't want to bunch things up too much. I think the top of the mash vessel will be 6 to 6'6". I have to measure a few things to figure that out.

I'd like the mash process to basically run unattended. I love brewing and all, but I don't get many days where I can sit and watch the temp of the mash for several hours at a time. I'd get a lot more brewing in if I had a system that I could set up and start and then check every hour or so.

It would be really great if I could brew on a work night without going to bed at 1AM ! (I brew beers with multi step mash schedules and my present system is very slow to raise temps.) I can see a couple ways for this to happen. 1) I set up the stand and my wife starts it early in the afternoon and I sparge when I get home from work. Basically the mash cooking happens while I am at work. 2) I come home from work at lunch and start the mash cooking. 3) I come home from work early, like 4PM with the stand already set up and loaded and the water already up to temperature.

I can't see a problem with running unattended, except if the bed /compacted or stuck for some reason. I'd almost like to put a flow meter on the wort flow, but that would be overkill right ? I could add a USB camera or two to the laptop and watch it over the Internet ! At least with a HERMs you don't have to worry about scorched wort if the flow stops. And with the computer controlling the temp in the heater water, nothing is going to get out of control.

I'll set the laptop on a desk/bench/cart a ways away from the action. With RS232, I could make the cable up to 30 feet long. I'd love to put it right on the stand, but I'm worried about the heat and it getting dirty or WET !

I was thinking of adding a fold out shelf to the stand, to set things like a paper notebook, hops, etc right there. Thinking about it again, I say its a bad idea because things will get wet and dirty there. Better to put them on a nearby desk/bench/cart, right ? And yet I always seem to have stuff laying on the floor at my feet when I brew ! I hate that.

Do you think having the mash vessel high up will be a pain ? I can design the step so that it holds a garbage can that the mash vessel tips into when I want to get rid of the spent grain.

I'd go single tier, but that kinda means you need 2 pumps and the stand becomes longer. Takes up more room in the garage when not brewing. I like the idea of a tipping mash vessel too.

I'll need 240V for the heating elements. That means it will be difficult to take it to my local brew club or my friends place to do a brew. It also means that when I move I'll need to wire 240V into the garage/patio before I can brew. I never brew inside the house. Maybe its just me.

I'll make the stand out of mild steel and paint it. I'd like to use SS or aluminum, but the cost and difficulty welding it rule it out. I'm a good stick welder and I have a shop to build this setup myself if I use mild steel.

I'll be brewing about 10 batches a year, mostly in winter. I like lagers and fruit beers, but my tastes are changing as I get more experienced. I want a brew system that will last and I'll be happy with for the next 10-15 years. Part of the reason I haven't brewed for 6 years is because my old equipment sucked and it was hard to get a good result. (Temp control problems, slow temp rise, setting up and clean up was a hassle, etc.) Its a crying shame that I stopped brewing.

What would you change to make this design better ?

Thanks.

First a diagram of the layout.

http://www.pbase.com/me2001/image/71581680

Its a clone of a More Beer 1550.

http://morebeer.com/product.html?product_id=15198

I have a HERMS unit now, but I need to change the mash setup and I don't like my stand. I want something compact and yet nice to use. I don't want to be dragging out kettles and stands and pumps every time I want to brew something. I want to roll out one stand, plug it in and start brewing.

I already have most of the pieces to build this design.

My new design is a HERMS design but instead of putting the heat exchange coil in the hot water tank, it goes in its own heating tank. For now I have that being a corny keg, but I might change that. I'd like something a bit smaller. The heating tank is stirred via a pump so that the heat exchange between the water and the wort coil is good.

Here is another system designed like this.

http://home.comcast.net/~verhulst/RIMS/

My heater tank and hot water tank will each have a computer controlled 4.5KW electric element. The whole heating system is controlled via laptop linked to the controls box by an RS232 cable. The pump speed is manually controlled by a dimmer switch.

There will be electronic temperature sensors in the mash vessel, the hot water tank and the heater tank. Temps will be displayed and plotted on the laptop.

The mash vessel is a 10 gallon Gott with a false bottom. It tips for easy emptying. The boiling kettle and hot water kettle are 15.5 gallon Sanke kegs. I want to be able to brew enough wort to fill 2 6 gallon carboys.

There will be no hard plumbed lines. No electronic control valves. All inlets/outlets will have quick connects. To change the flow, a few pieces of hose with QCs will be moved.

The only burner is under the boiling kettle. I didn't put a propane tank on the stand because I didn't want it near the burner heat and someday I'll probably connect this to natural gas and then I won't need a propane tank.

All the tanks will have level gauges.

I want it to be easy to clean after brewing. I am wondering how I will get the boiling kettle and hot water kettle totally empty when I am done brewing. Unplug them and turn them upside down ?

How does one dry the inside of hoses ? I am thinking of using an air hose to blow out the counter flow chiller after its been flushed. I am still trying to figure out how to get the heat exchange coil empty in the heater vessel.

I might put the valves in the bottom of the hot water tank and the mash vessel, not the side as is traditionally done.

The cart will be about 18 inches wide and nearly 4 feet long. I could make it shorter, but I don't want to bunch things up too much. I think the top of the mash vessel will be 6 to 6'6". I have to measure a few things to figure that out.

I'd like the mash process to basically run unattended. I love brewing and all, but I don't get many days where I can sit and watch the temp of the mash for several hours at a time. I'd get a lot more brewing in if I had a system that I could set up and start and then check every hour or so.

It would be really great if I could brew on a work night without going to bed at 1AM ! (I brew beers with multi step mash schedules and my present system is very slow to raise temps.) I can see a couple ways for this to happen. 1) I set up the stand and my wife starts it early in the afternoon and I sparge when I get home from work. Basically the mash cooking happens while I am at work. 2) I come home from work at lunch and start the mash cooking. 3) I come home from work early, like 4PM with the stand already set up and loaded and the water already up to temperature.

I can't see a problem with running unattended, except if the bed /compacted or stuck for some reason. I'd almost like to put a flow meter on the wort flow, but that would be overkill right ? I could add a USB camera or two to the laptop and watch it over the Internet ! At least with a HERMs you don't have to worry about scorched wort if the flow stops. And with the computer controlling the temp in the heater water, nothing is going to get out of control.

I'll set the laptop on a desk/bench/cart a ways away from the action. With RS232, I could make the cable up to 30 feet long. I'd love to put it right on the stand, but I'm worried about the heat and it getting dirty or WET !

I was thinking of adding a fold out shelf to the stand, to set things like a paper notebook, hops, etc right there. Thinking about it again, I say its a bad idea because things will get wet and dirty there. Better to put them on a nearby desk/bench/cart, right ? And yet I always seem to have stuff laying on the floor at my feet when I brew ! I hate that.

Do you think having the mash vessel high up will be a pain ? I can design the step so that it holds a garbage can that the mash vessel tips into when I want to get rid of the spent grain.

I'd go single tier, but that kinda means you need 2 pumps and the stand becomes longer. Takes up more room in the garage when not brewing. I like the idea of a tipping mash vessel too.

I'll need 240V for the heating elements. That means it will be difficult to take it to my local brew club or my friends place to do a brew. It also means that when I move I'll need to wire 240V into the garage/patio before I can brew. I never brew inside the house. Maybe its just me.

I'll make the stand out of mild steel and paint it. I'd like to use SS or aluminum, but the cost and difficulty welding it rule it out. I'm a good stick welder and I have a shop to build this setup myself if I use mild steel.

I'll be brewing about 10 batches a year, mostly in winter. I like lagers and fruit beers, but my tastes are changing as I get more experienced. I want a brew system that will last and I'll be happy with for the next 10-15 years. Part of the reason I haven't brewed for 6 years is because my old equipment sucked and it was hard to get a good result. (Temp control problems, slow temp rise, setting up and clean up was a hassle, etc.) Its a crying shame that I stopped brewing.

What would you change to make this design better ?

Thanks.