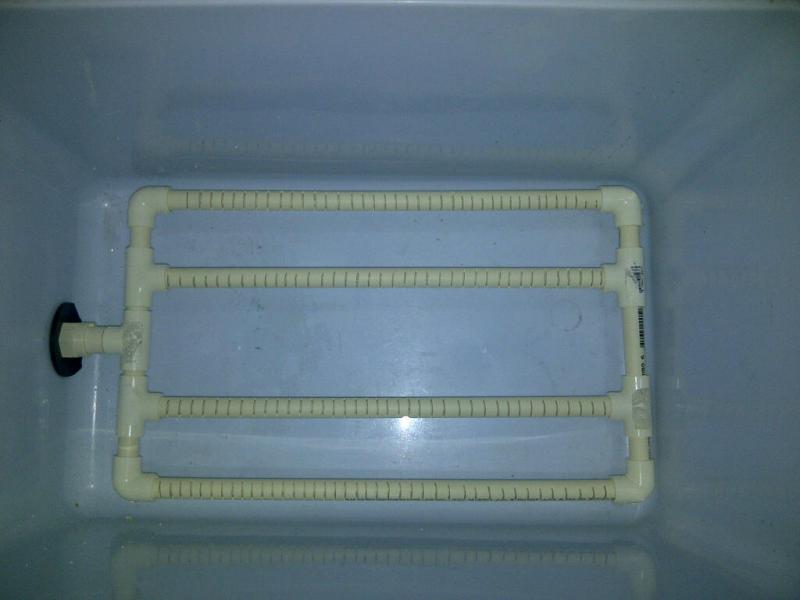

I just finished making a mash tun out of a 48 qt rubbermaid cooler that I had sitting around the house. I've read about all the discussions of what's better between ss braid, copper manifold, and CPVC Manifold.

My choice narrowed down quickly to SS braid vs. CPVC Manifold because the current price of copper.

I decided on CPVC for future versatility and after reading John Palmer but it's also just personal preference.

I've seen some design and costs but most of them seem out of date on pricing. So i decided I'd post my design and updated pricing as of May 5th, 2011.

Equipment Needed:

48 qt Rubbermaid Cooler

Qty 1 - 10 ft Section 1/2" CPVC pipe - $2.60

Qty 5 - 1/2" Tee CPVC - $.19 each

Qty 4 - 1/2" 90 degree Elbow CPVC - $.29 ea

Qty 1 - 1/2" CPVC Female Coupling Adapter - $.67

Qty 1 - 3/4" ID x 1 1/2" OD Rubber Washer - $.86

Size does not matter since you can cut the hole size you want. I could not find anything above 5/16" ID

Qty 1 - 3/4" ID Flat Steel Cut Washer (I used a Rosette washer but may be more difficult to find) - $.40

Qty 1 - Brass 1/2" x 1/2" male to male nipple (1 1/2" to 2 1/2" length depending on cooler width) - $2.52

Qty 1 - 1/2" x 3/8" hosetail (can use 1/2" x 1/2" hosetail) - $2.56

Qty 1 - 1/2" brass full port threaded ball valve - $7.52

Total Investment - $20.64 + cost of cooler.

All Items were purchased at Home Depot.

There are cheaper alternatives with CPVC if you don't mind using glue.

I just didn't want any chance of contamination so I didn't do this.

You can buy 1/2" CPVC ball valves threaded or unthreaded and either glue in the pipe or try to find to find the correct fittings and adapters.

Hope this is useful and helpful to anyone considering making one instead of buying it!

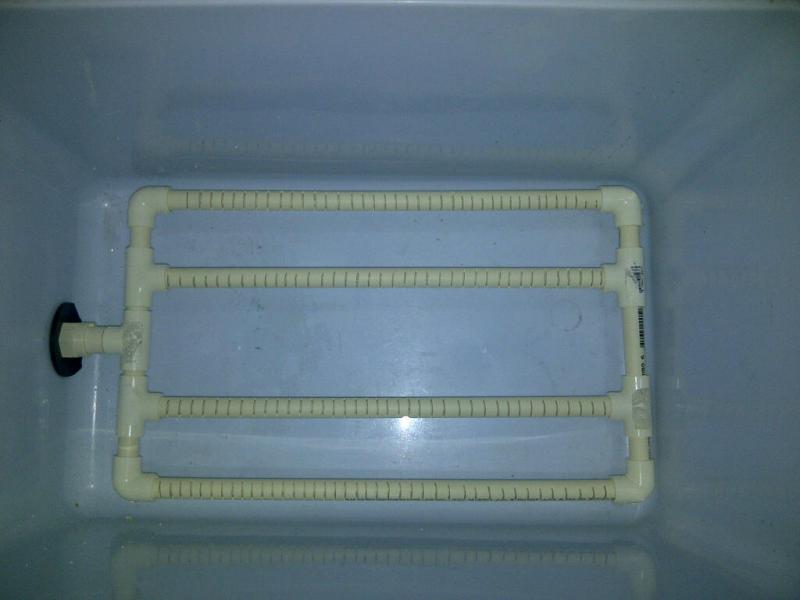

My choice narrowed down quickly to SS braid vs. CPVC Manifold because the current price of copper.

I decided on CPVC for future versatility and after reading John Palmer but it's also just personal preference.

I've seen some design and costs but most of them seem out of date on pricing. So i decided I'd post my design and updated pricing as of May 5th, 2011.

Equipment Needed:

48 qt Rubbermaid Cooler

Qty 1 - 10 ft Section 1/2" CPVC pipe - $2.60

Qty 5 - 1/2" Tee CPVC - $.19 each

Qty 4 - 1/2" 90 degree Elbow CPVC - $.29 ea

Qty 1 - 1/2" CPVC Female Coupling Adapter - $.67

Qty 1 - 3/4" ID x 1 1/2" OD Rubber Washer - $.86

Size does not matter since you can cut the hole size you want. I could not find anything above 5/16" ID

Qty 1 - 3/4" ID Flat Steel Cut Washer (I used a Rosette washer but may be more difficult to find) - $.40

Qty 1 - Brass 1/2" x 1/2" male to male nipple (1 1/2" to 2 1/2" length depending on cooler width) - $2.52

Qty 1 - 1/2" x 3/8" hosetail (can use 1/2" x 1/2" hosetail) - $2.56

Qty 1 - 1/2" brass full port threaded ball valve - $7.52

Total Investment - $20.64 + cost of cooler.

All Items were purchased at Home Depot.

There are cheaper alternatives with CPVC if you don't mind using glue.

I just didn't want any chance of contamination so I didn't do this.

You can buy 1/2" CPVC ball valves threaded or unthreaded and either glue in the pipe or try to find to find the correct fittings and adapters.

Hope this is useful and helpful to anyone considering making one instead of buying it!