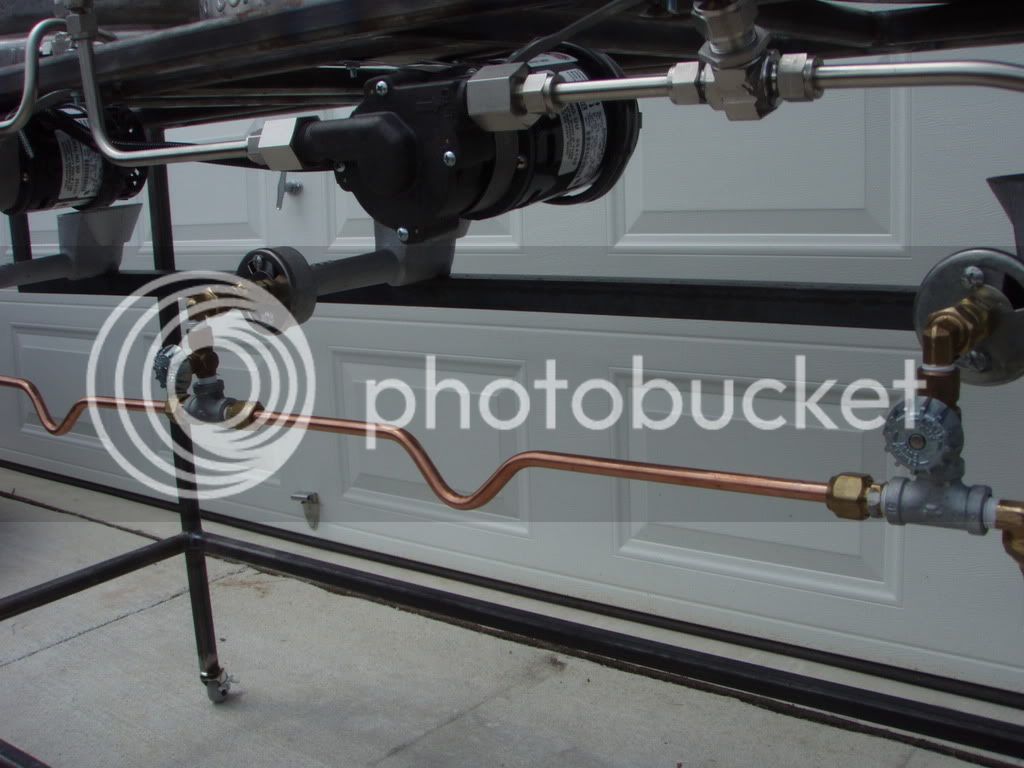

I just thought that I would let you all know that construction of the AG Monster is underway. It is a triple vessel, triple burner, dual pump, CF heat exchanger brewing machine. Frame welding will commence this weekend. Pictures and details to follow.

I am confused, however, on how exactly to construct the sparging device. I have never seen one in operation. Is there a specific height that it must be away from the grain bed? What do you recommend?

Thanks

Nate

I am confused, however, on how exactly to construct the sparging device. I have never seen one in operation. Is there a specific height that it must be away from the grain bed? What do you recommend?

Thanks

Nate

.

.