oldstyle69

Well-Known Member

Nice.

Any more ladder rigs out there?

Folding rigs?

Any more ladder rigs out there?

Folding rigs?

Running of my houses natural gas, and there's a giant vent hood (air/moisture tight) with a hydroponics vortex fan venting gases and moisture. Nobody upstairs could smell the boiling wort.

I see what you did there... Is that a chevy wheel under your Boil Kettle? !!!! :rockin:

Could you describe how the vent system is constructed?

Score! I'll have make friends with some of the plumbers around here and see what I can find. Did you cut with a saw, grinder, torch, plasma, something else?

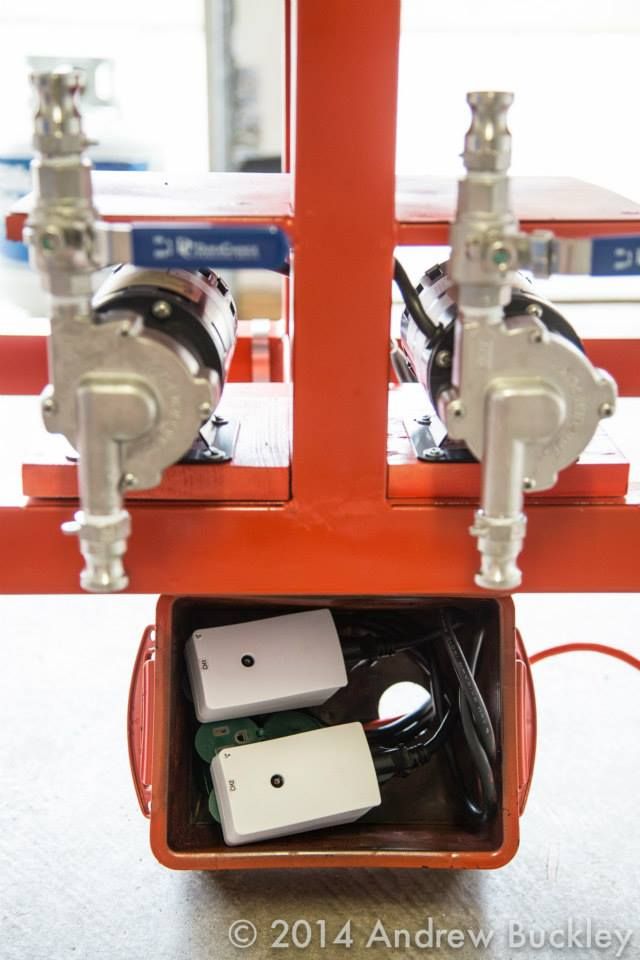

My rig:

Here's quick video, if you want to have a look. I didn't have the time to edit it, but it's still easier to see how it goes than explain it. Works quite well even without the lid. http://www.youtube.com/watch?v=VO8IlvWlKIYCould you describe how the vent system is constructed?

Sahweet! Love how it vents to the back.

Here's quick video, if you want to have a look. I didn't have the time to edit it, but it's still easier to see how it goes than explain it. Works quite well even without the lid.]

Terrific! Very helpful. A simple elegant solution. Hard to believe a computer fan can move that much air.

Looks almost as much snow and cold as here in Minnesota.

Is the toaster for sale?

Enter your email address to join: