pvtschultz

Well-Known Member

I have been squirreling away money for most of the summer to build an eBIAB brewery in my basement. My work came through with some bonus money again this year which gave me enough money to pull the trigger on the build. I've been working in the background on this for a few months and never posted anything, so now you can have it all at once.

The premise of the the design is to be able to brew year-round without having to drag all of my equipment outside to the garage to use the Cajun burner. I have a decent sized laundry area with 30a 220VAC service, an outside vent, and water; everything needed to brew beer. I decided to stick to a single vessel BIAB setup. I opted for a 5500W element since I have 30A available and I may want to try a larger batch down the road. I legally acquired a couple 1/2 barrel kegs from a friend in the business (use for the second is TBD) and a cart made of extruded aluminum from my employer.

I have a for-profit word carving hobby that used to share the same area as the laundry so that needed to be be partitioned off first before anything could happen to keep the dust out. But first, we needed to clean the basement! I didn't take pictures, but let's just say the folks at Good Will got two truck loads of stuff. I got the wall built, found space for the ferm chest freezer, and started in on the build.

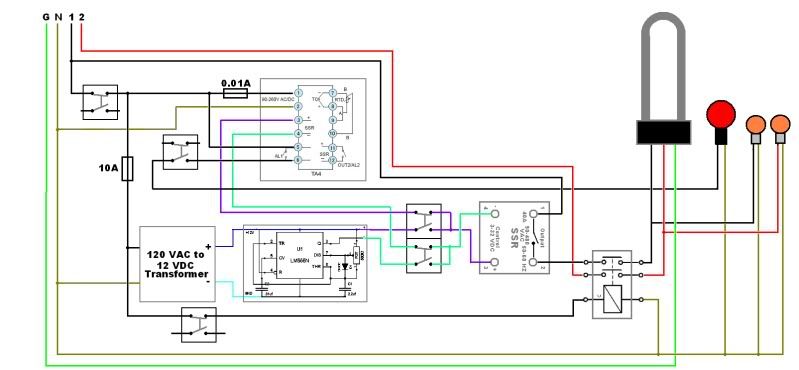

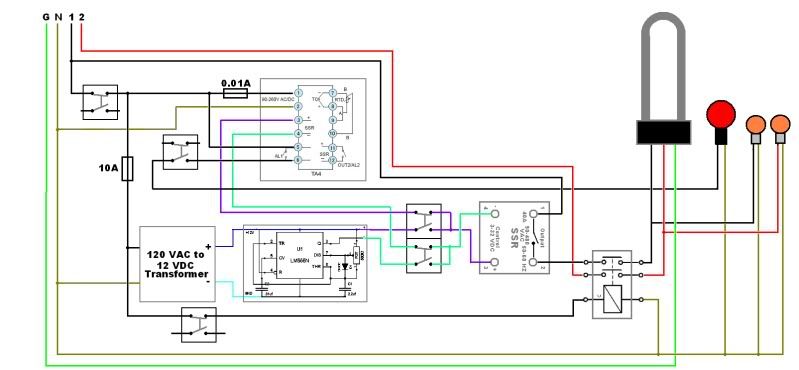

While I was accumulating funds and parts, I took some time to draw up my wiring diagram. P-J has been infinitely helpful (even though he doesn't know it yet) with general design. I opted for a cheap controller which ended up not having a manual PWM function. To rectify, I added a PWM circuit to the control panel which would otherwise be redundant with the Auber unit. BUY THE AUBER UNIT AND SAVE THE EXTRA WORK. So here's the schematic.

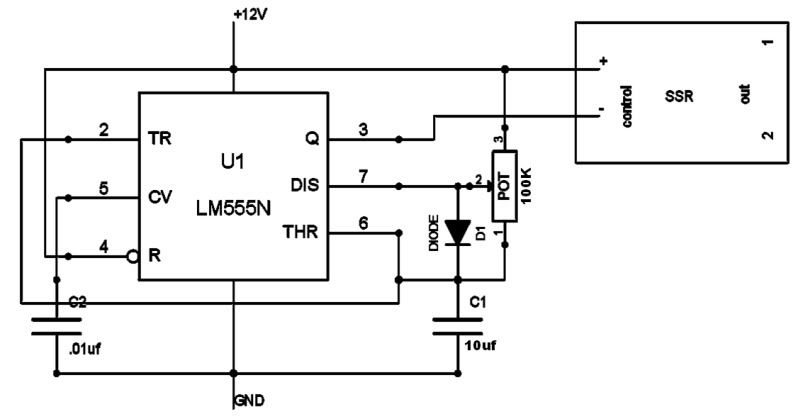

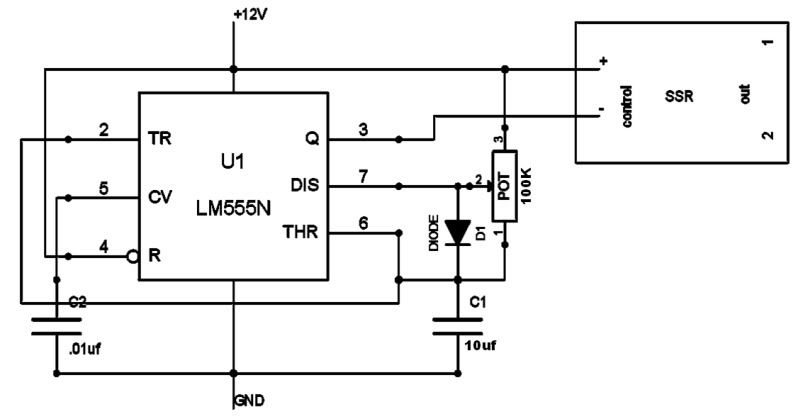

And the PWM circuit that I used.

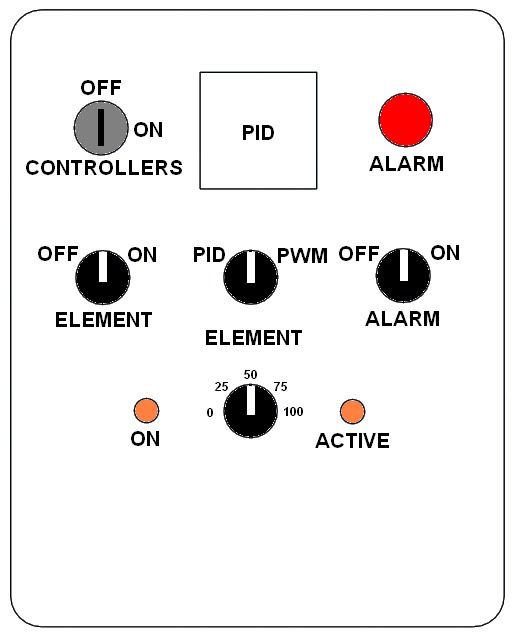

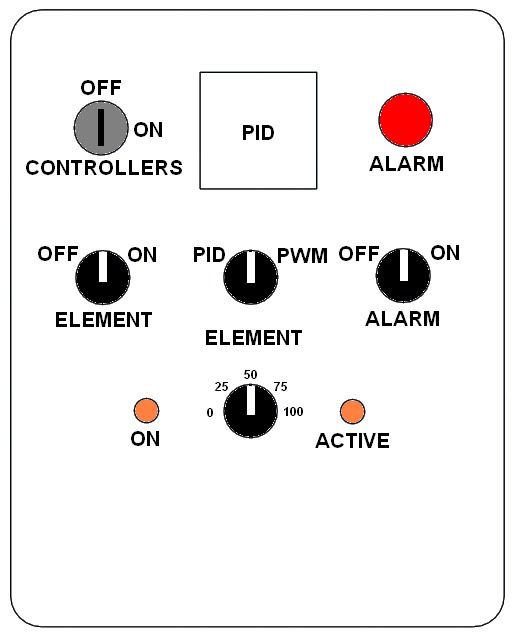

And the layout that I decided for the panel.

The premise of the the design is to be able to brew year-round without having to drag all of my equipment outside to the garage to use the Cajun burner. I have a decent sized laundry area with 30a 220VAC service, an outside vent, and water; everything needed to brew beer. I decided to stick to a single vessel BIAB setup. I opted for a 5500W element since I have 30A available and I may want to try a larger batch down the road. I legally acquired a couple 1/2 barrel kegs from a friend in the business (use for the second is TBD) and a cart made of extruded aluminum from my employer.

I have a for-profit word carving hobby that used to share the same area as the laundry so that needed to be be partitioned off first before anything could happen to keep the dust out. But first, we needed to clean the basement! I didn't take pictures, but let's just say the folks at Good Will got two truck loads of stuff. I got the wall built, found space for the ferm chest freezer, and started in on the build.

While I was accumulating funds and parts, I took some time to draw up my wiring diagram. P-J has been infinitely helpful (even though he doesn't know it yet) with general design. I opted for a cheap controller which ended up not having a manual PWM function. To rectify, I added a PWM circuit to the control panel which would otherwise be redundant with the Auber unit. BUY THE AUBER UNIT AND SAVE THE EXTRA WORK. So here's the schematic.

And the PWM circuit that I used.

And the layout that I decided for the panel.