flatulentfox

Well-Known Member

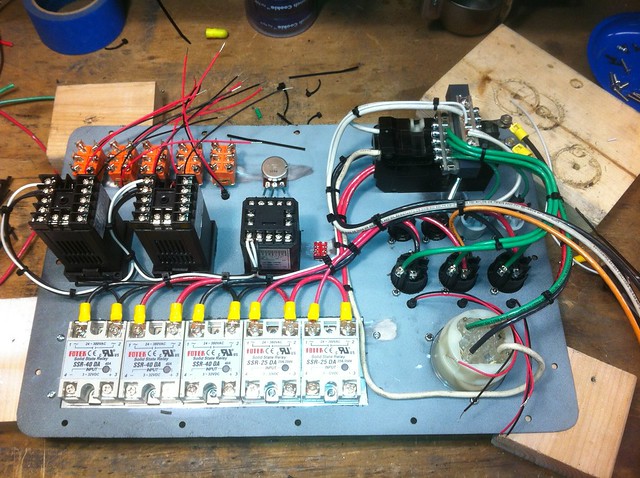

I've been planning and thinking for about six months now. I finally have all the parts for the control panel and am almost ready to start wiring. I am currently painting the sheet metal panel and will hopefully have it wired by the end of next week.

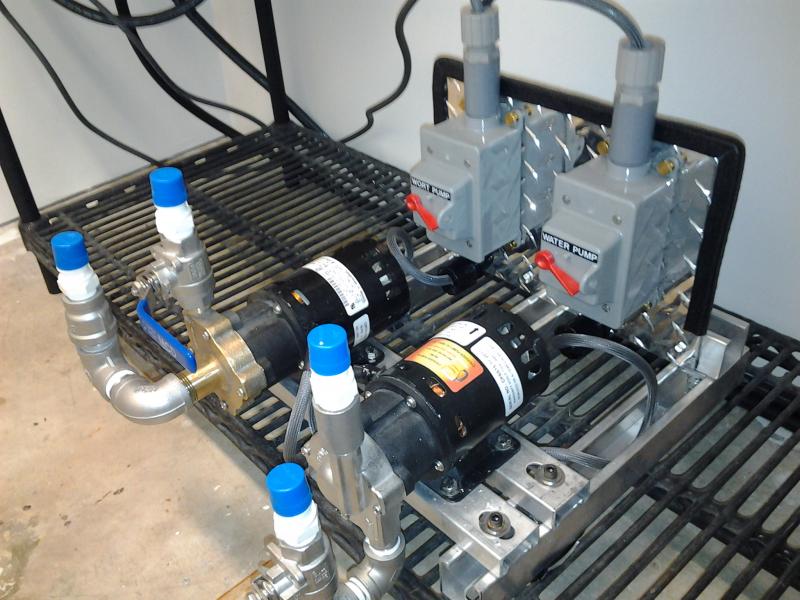

There will be two PIDs and one PWM circuit. The first output (SSR #1) will be switchable to be controlled by PID #1 or by the PWM circuit. The second output (SSR #2) will be controlled by PID #2 and be switchable between 120V and 240V. The third output (SSR #3) will always be controlled by the PWM circuit. There will be two outputs (switched 25A SSRs) for pumps. This gives me the capability to control a full three vessel single tier rig or something as simple as a BIAB system. I plan on using it now as a two vessel two tier Brutus 20 type system. Here are a few pics.

More to come. I have my kegs and have cut them open and started polishing them...

There will be two PIDs and one PWM circuit. The first output (SSR #1) will be switchable to be controlled by PID #1 or by the PWM circuit. The second output (SSR #2) will be controlled by PID #2 and be switchable between 120V and 240V. The third output (SSR #3) will always be controlled by the PWM circuit. There will be two outputs (switched 25A SSRs) for pumps. This gives me the capability to control a full three vessel single tier rig or something as simple as a BIAB system. I plan on using it now as a two vessel two tier Brutus 20 type system. Here are a few pics.

More to come. I have my kegs and have cut them open and started polishing them...