I've been working this 1.5bbl system(pictures above), and I've finally got all the plumbing done, valves hooked up, and ready to go... or so I thought.

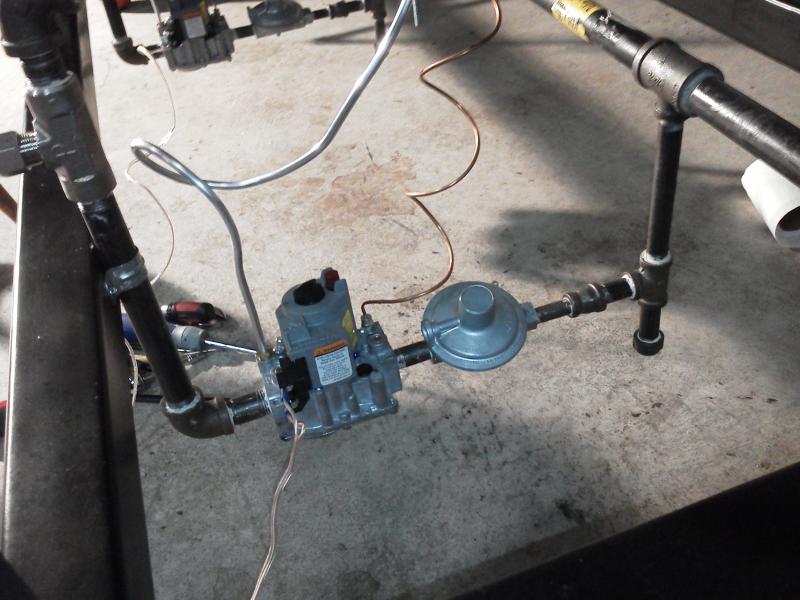

It's a single tier, 3 burner system, with the HLT and mash tun controlled with honeywell valves. Here's the setup from tank to burner.

A 500K btu inlet fitting on my 20lb cylinder.

http://www.tejassmokers.com/images/IMG_1194.JPG That is connected to a non-adjustable regulator that is set to 0.4psi and has a capacity of 140K BTU. Then a Brasscraft 24" furnace/boiler gas line. It has a BTU capacity of 130K BTU and is 1/2" ID, I believe. I've got this connected to my main gas line on the rig, which is a 3/4" iron gas pipe. This is where I have 3 branches, one going to each burner. For the valve controlled burners, there is a T that reduces to 3/8" coming off the main line. Then a reducer to 1/4" pipe. This goes into a fixed pressure regulator with 0.5psi output and a 200K btu capacity. This goes directly into the honeywell valve

http://customer.honeywell.com/honeywell/ProductInfo.aspx/VR8200A2132 . It doesn't say it on the sight, but the valve has a max capacity of 200K btu, by adjusting the pressure regulator on the valve. It says this on the box it came in. The outlet (1/2") goes to a 1/2" needle valve, then to the burner. The burner is

http://www.tejassmokers.com/newproducts_page6.htm , the 20 jet 200k btu version.

I realize I'm not going to get the 200K btu I want with the gas hose and regulator I've got attached to the cylinder. I just put those on to check for leaks and test out the valves. The burner that isn't controlled by a honeywell valve works fine. It's just 1/2" pipe all the way from the main gas line with a 1/2" needle valve. I think it probably gets somewhere a bit over 100k btu. The valve controlled burners are horrible. Nowhere near enough gas flow. Very lazy yellow flame that I don't think even gets up to 50k btu. Here's a couple problems I've had with the valves. I've turned the pressure regulator screw in the valve all the way up, and it had absolutely no affect. I turned it down, and still no affect. Both burners do this same thing. Also, the pilot light (Q314A model) flames won't adjust either! I turned the pilot light adjustment screw both ways, with no affect. The problem with this is that one of the pilots is wayy to hot, and makes the thermocouple glow bright red.

When I have all 3 burners going at once, they still do exactly as what I described. They don't seem to be diminished at all, even though all 3 are going... the valve controlled flames are still very weak.

Is it the regulator or hose on my cylinder, or the gas valves?

So frustrating!!!!!!!!

Sorry there isn't any pictures. I can't get my picture uploader to work.

Thanks for any and all help. I'll post back with pics if I can get my computer to work correctly.