Compacto

Active Member

- Joined

- Mar 17, 2015

- Messages

- 39

- Reaction score

- 27

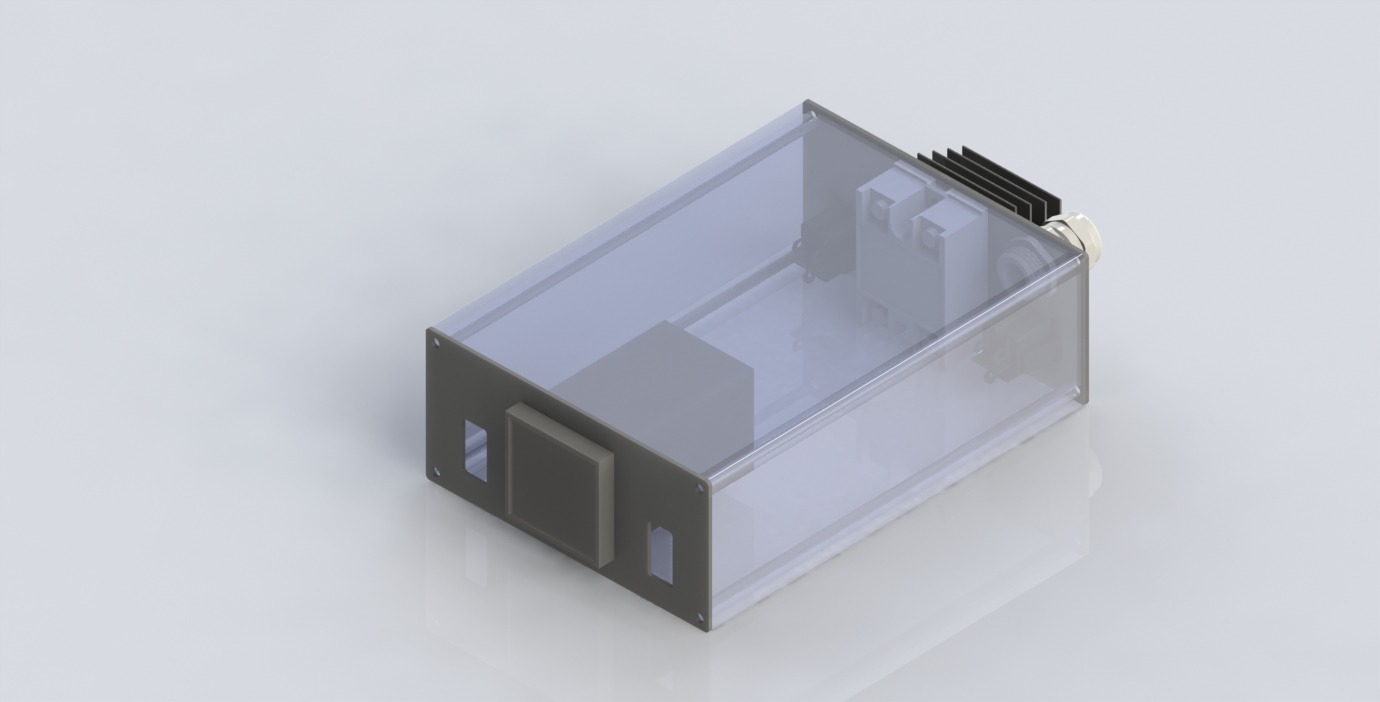

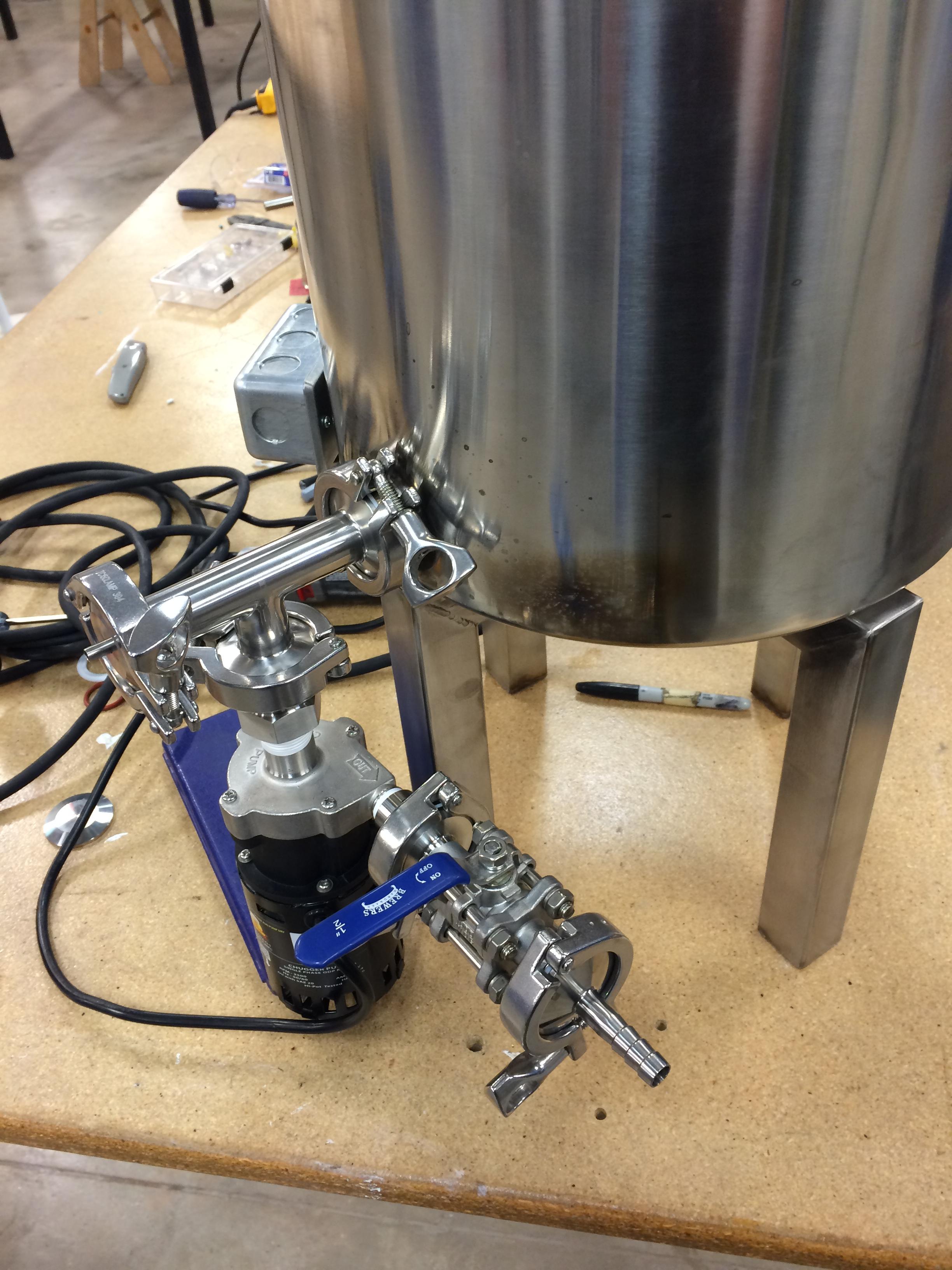

I'll be building a system in the same vein as the Grainfather/BIAC over the next few weeks and will use this thread to track it. I wanted something I could use indoors, had a small footprint and was electric/automated and I could tuck away when not in use. Really liked the idea of those all-in-one style homebrewing systems but am too stubborn to fork out the cash for one. So building my own, that's what homebrewings about right...? I wasn't going to attempt to use the vessel to ferment like the BIAC because carboys are cheap and that's too long to wait between brews.

I'll be using...

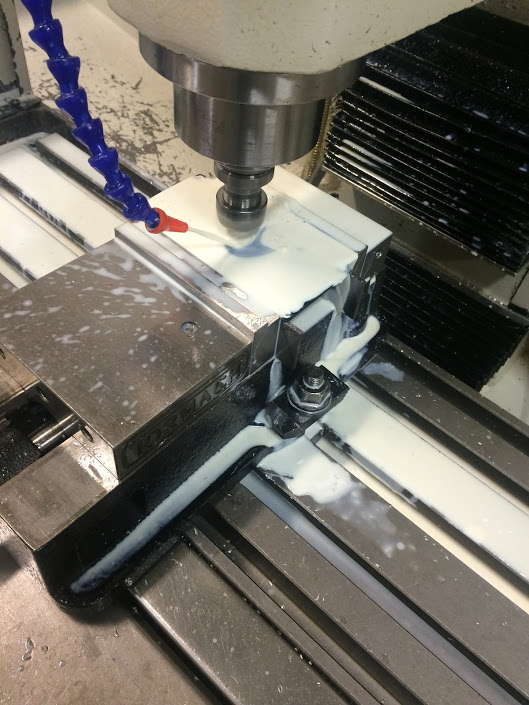

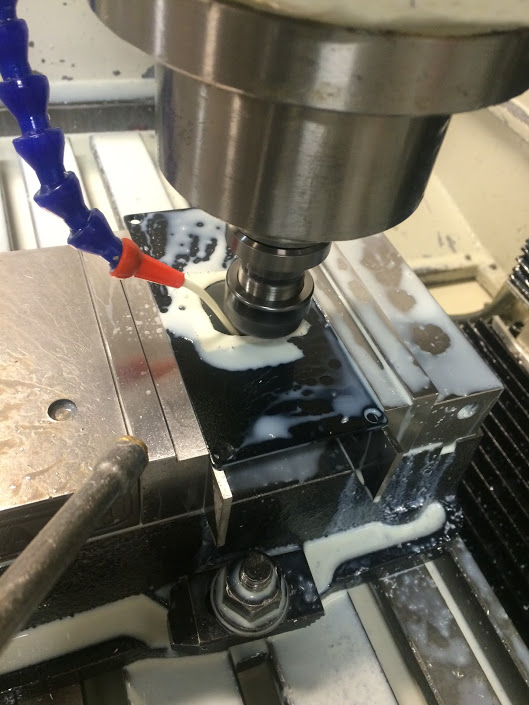

This week I've received the kettle and started in on the stand. I had planned to weld the legs to the kettle but upon receiving it realized it was a really really thing 20g (claimed) that likely would warp way to much to be welded too. Think I'll end up using one of the solder flanges from BrewHardware instead of welding to it. The stand will hold the pump and house the CF inside the legs, just got to wind it a bit tighter to fit in. I've got some SS spring toggle latches coming in that will secure the kettle to the stand.

Next will be the pump and coil. I used a 120v 2000w on my last setup and it really struggled with 6 gallons so I'm hoping the 240v 3750w BC wil remedy that. The pump will do a continuous sparge and to recirculation chill and then clean/sanitize the system once done.

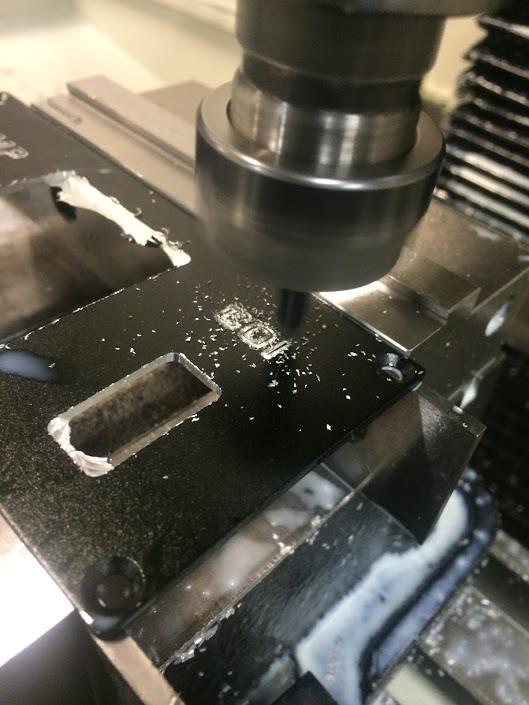

16g 1.5" 304SS for the legs.

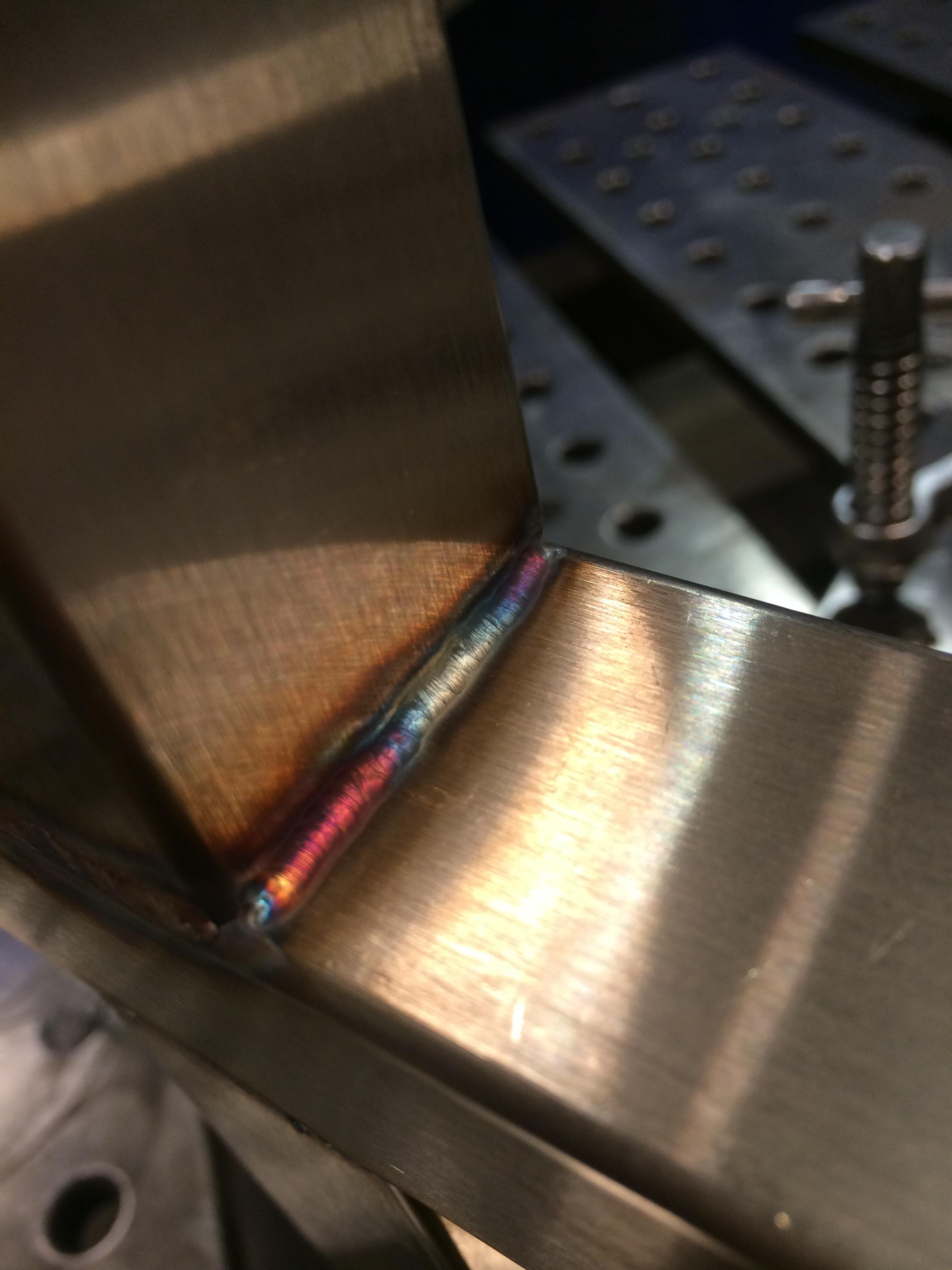

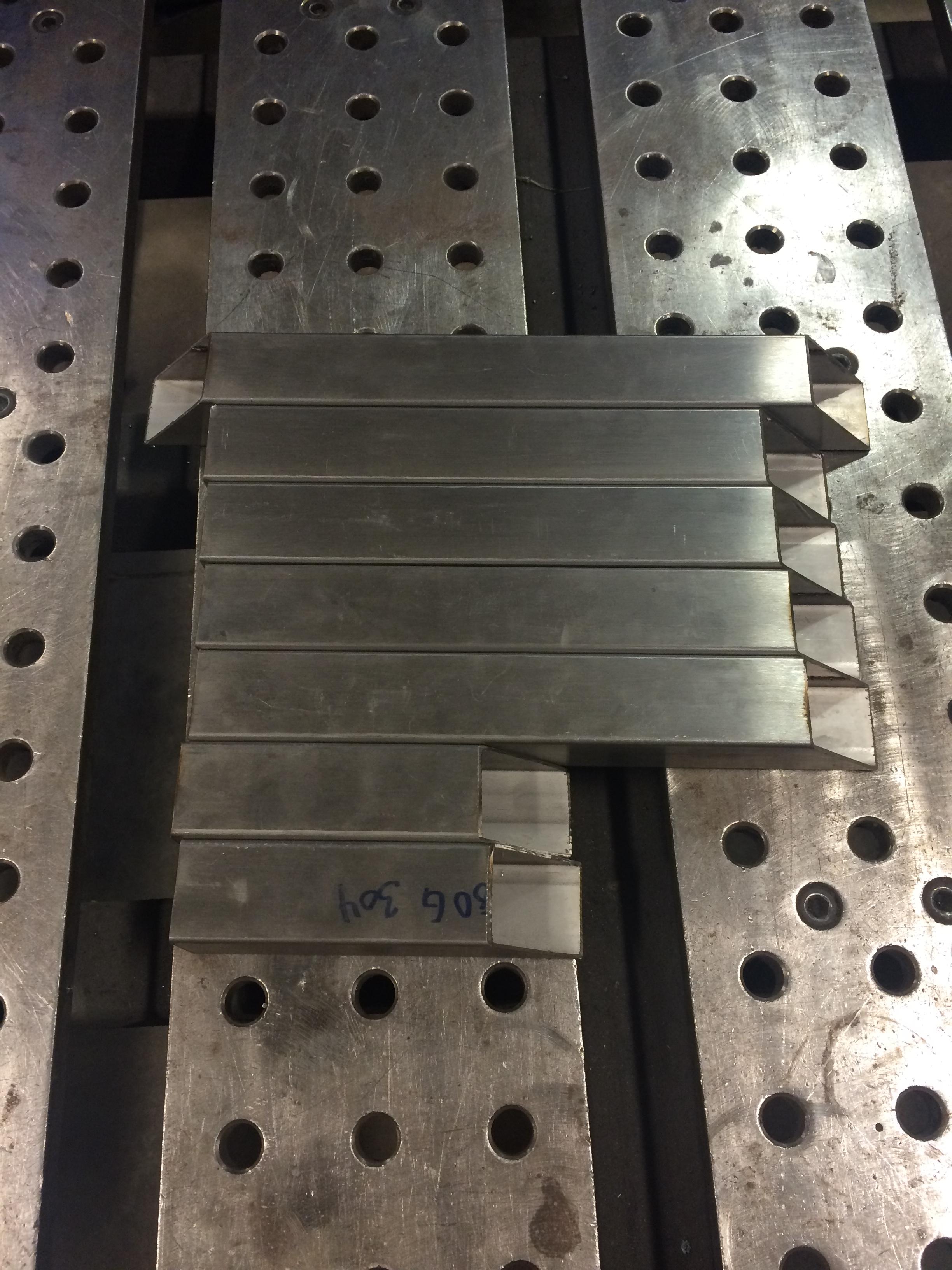

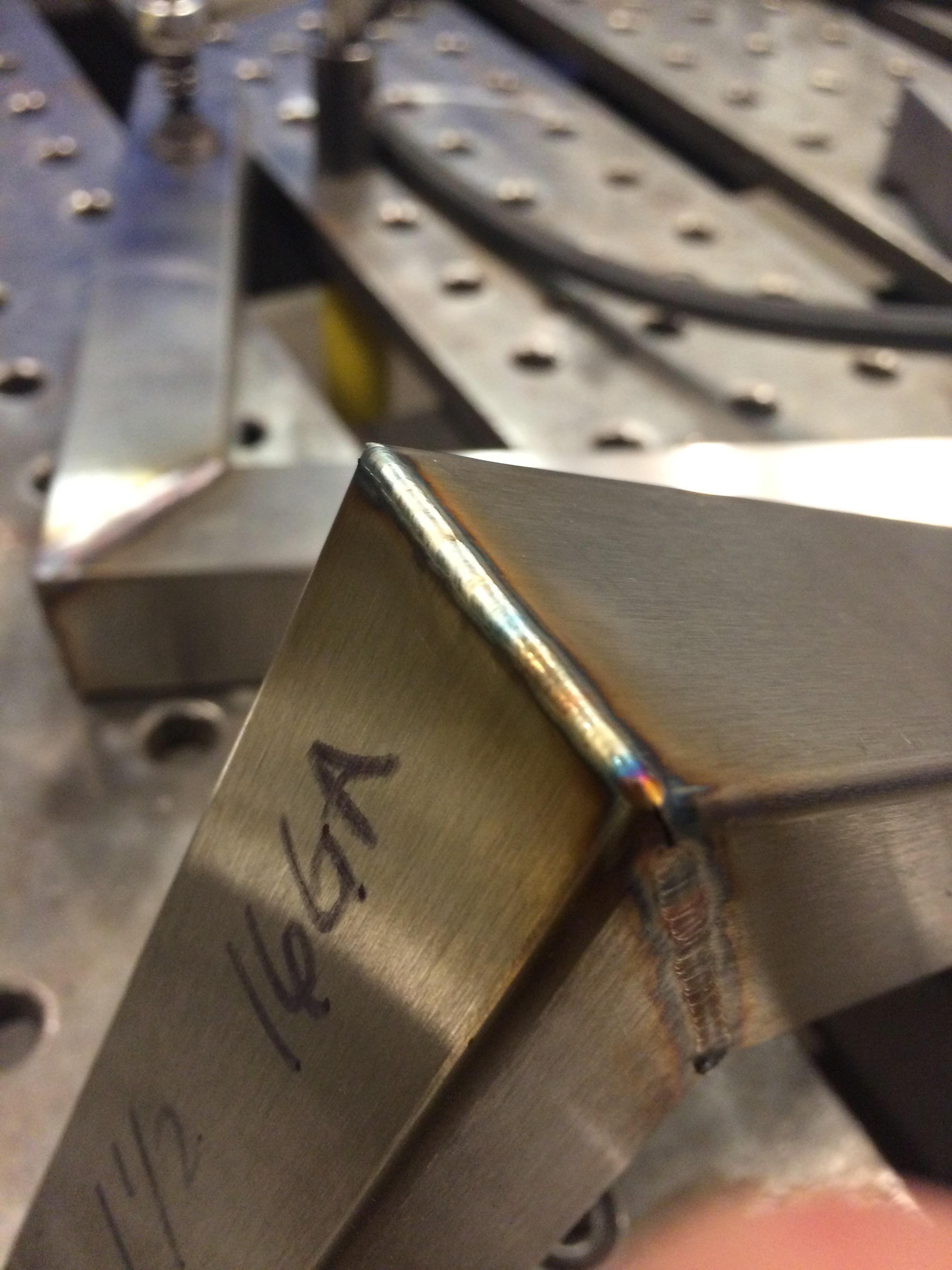

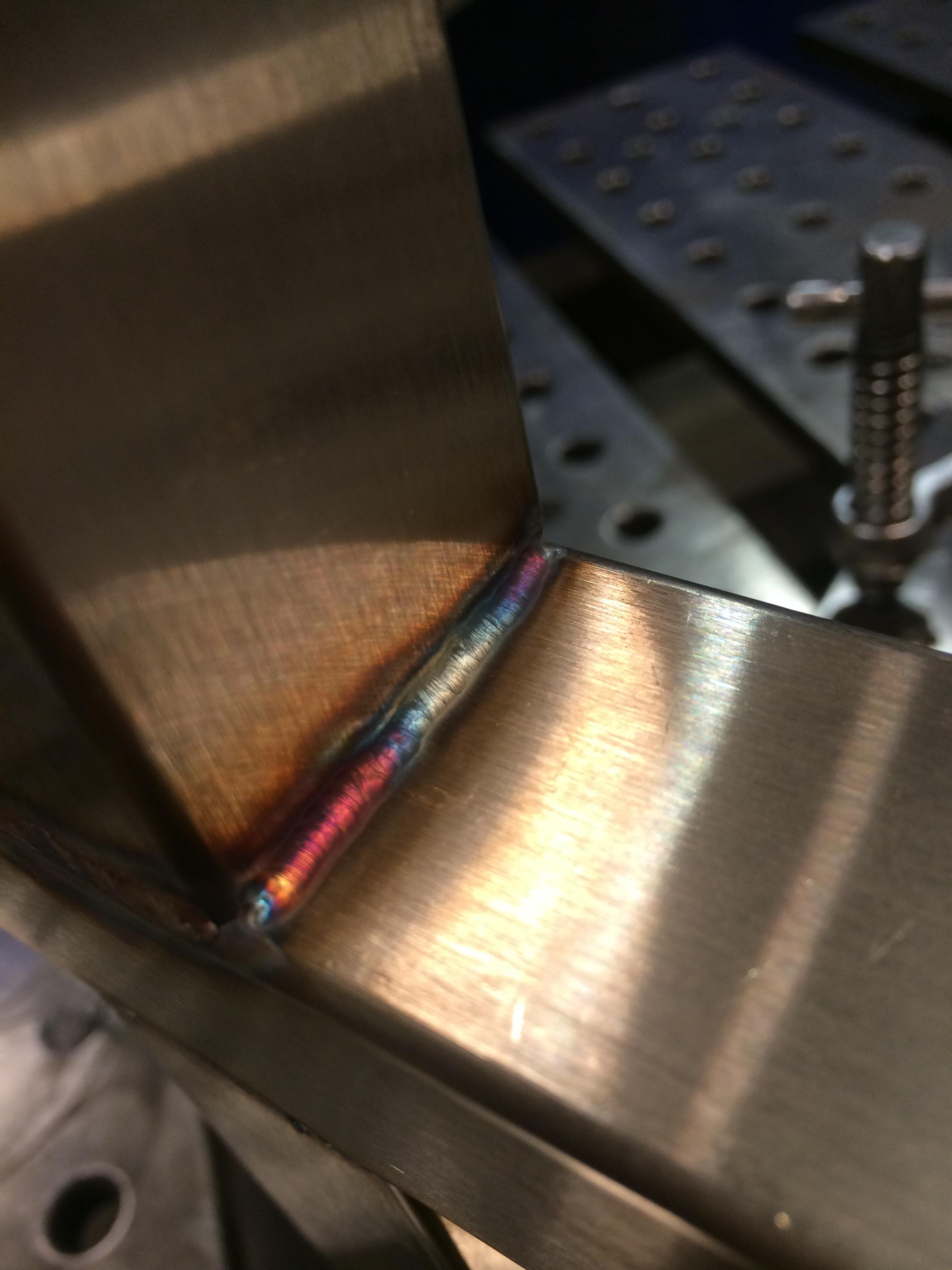

Fit up

Tacks

Welds

Welds

More welds...

Tapped plates for the wheels

Vinyl tubing, 100ft $10

I'll be using...

11g Bayou Classic with strainer (cheap, I know, but trying to keep cost down, $86 on Amazon is hard to beat)

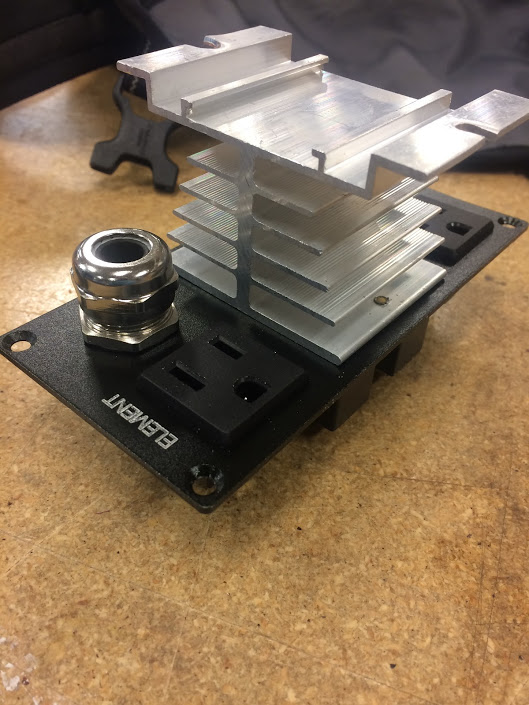

- PID/SSR setup

- SS center inlet Chugger

- 35' Counterflow w/ 15' Pre Chiller

- 3750w BoilCoil

- TC fittings

- Little stand thing to raise it to a comfortable height (always thought the Grainfather was too short on the ground and way too high on a counter...)

- Inline oxygenation

This week I've received the kettle and started in on the stand. I had planned to weld the legs to the kettle but upon receiving it realized it was a really really thing 20g (claimed) that likely would warp way to much to be welded too. Think I'll end up using one of the solder flanges from BrewHardware instead of welding to it. The stand will hold the pump and house the CF inside the legs, just got to wind it a bit tighter to fit in. I've got some SS spring toggle latches coming in that will secure the kettle to the stand.

Next will be the pump and coil. I used a 120v 2000w on my last setup and it really struggled with 6 gallons so I'm hoping the 240v 3750w BC wil remedy that. The pump will do a continuous sparge and to recirculation chill and then clean/sanitize the system once done.

16g 1.5" 304SS for the legs.

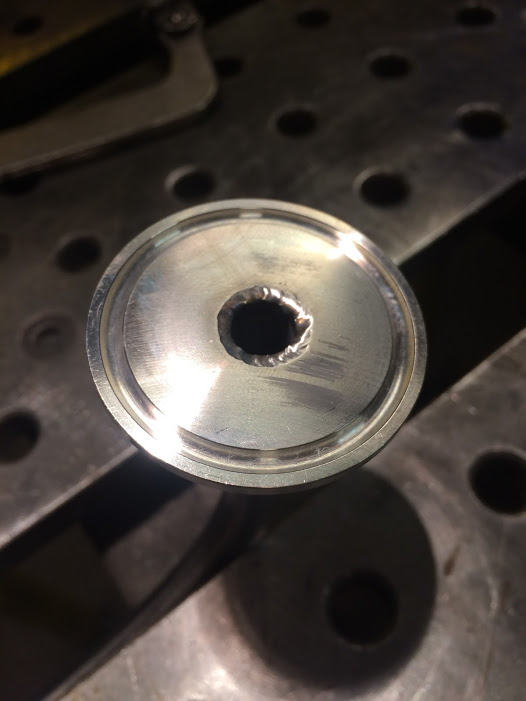

Fit up

Tacks

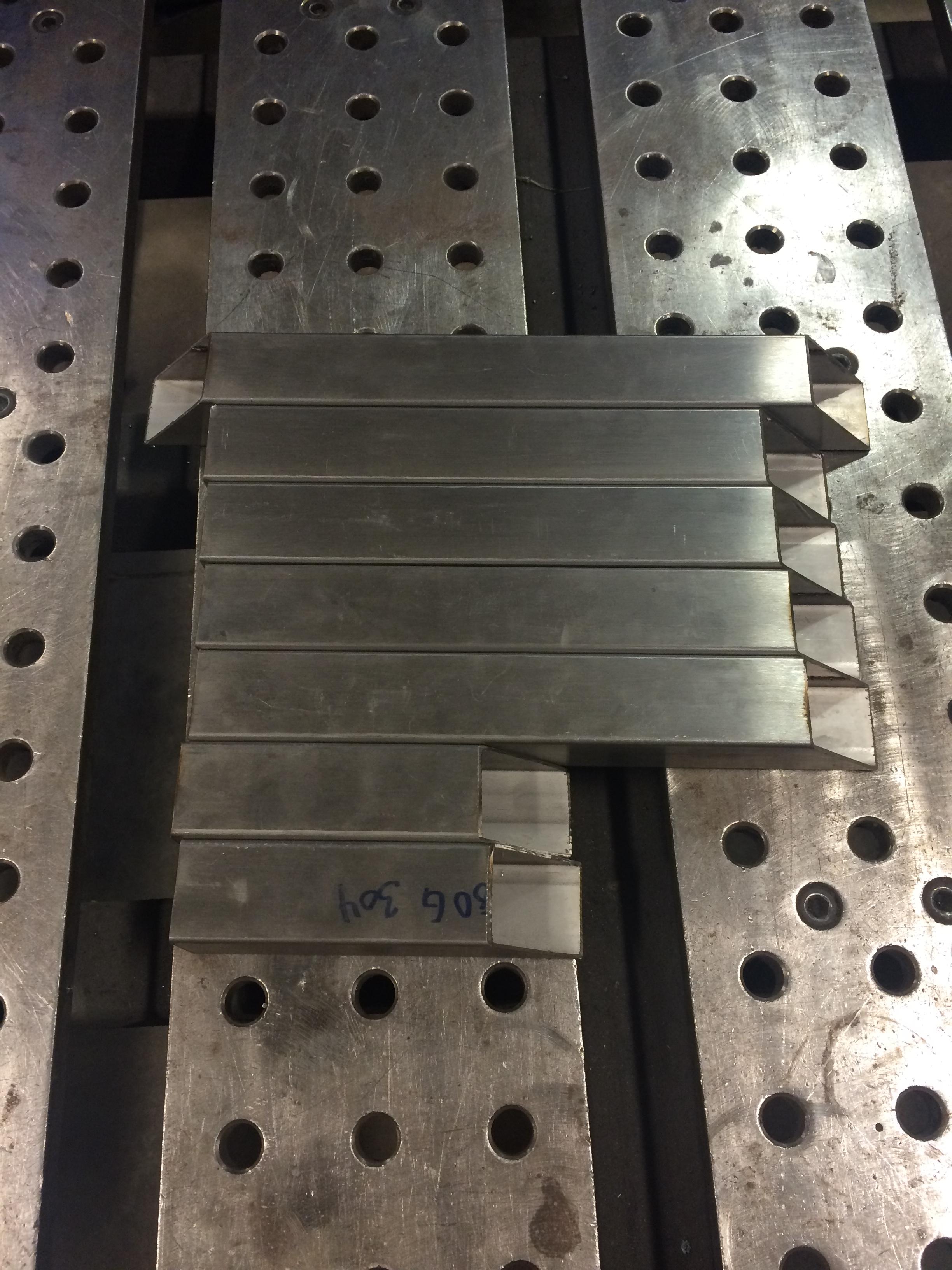

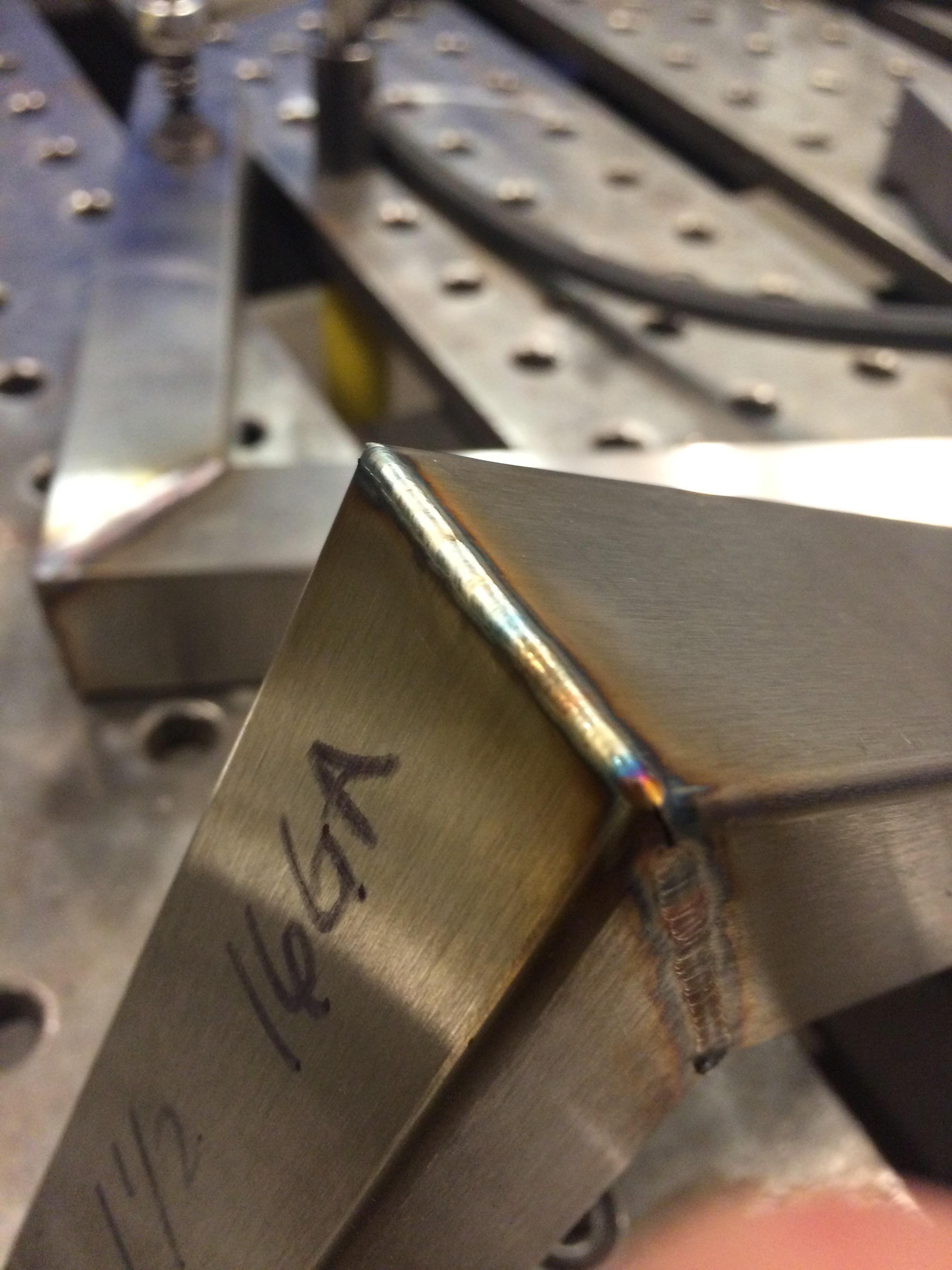

Welds

Welds

More welds...

Tapped plates for the wheels

Vinyl tubing, 100ft $10

same amount of work, more beer!

same amount of work, more beer!