JuanMoore

Getting the banned back together

Hi

If you believe that the compressor on a normal cheap / small freezer only cycles once or twice a day that's fine. My observation of brand new freezers does not match yours. For a very large freezer or a cold environment anything is possible. The published data from the manufacturer also does not back up the few cycles a day observation.

Bob

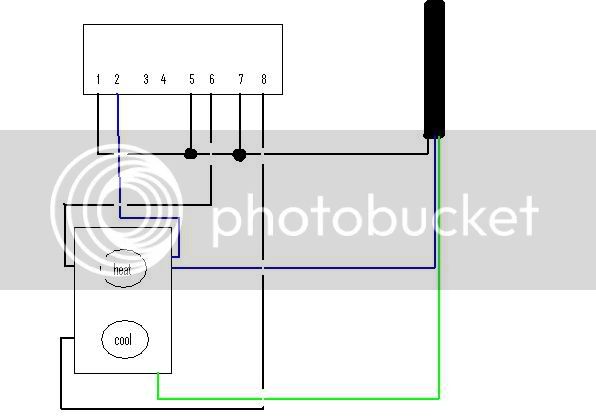

Seriously, are we still on this? First, I said "a few times a day", not once or twice. Second, the manufacturer data is for running the freezer at below freezing temperatures, with much less thermal mass inside of them, and with a completely different probe set-up than what I use, so it doesn't have any relation to what we're discussing. I don't just believe it cycles a few times a day, I know it. It's located right next to my desk in my home office, and on days when I work from home I can clearly hear it every time it turns on or off. The reason your observations don't match mine is because you haven't tried or observed the methods of temperature control that myself and many others have suggested.

Like I said earlier, simply raising the freezer temp from below freezing to beer serving temps should decrease the cycling significantly, reducing it to a fraction of what it was. If your system is cycling as often as the manufacturer specs at serving temps (as you suggested earlier), you really should re-think the way you have it set up. If you read the troubleshooting section of any freezer manual you'll see that the solutions for the freezer cycling too often or running continuously are to turn the thermostat up, and/or add thermal mass to the inside of the freezer. That alone should tell you that running the freezer at a significantly warmer temp and packed with a large thermal mass should reduce cycling to below the specs.

Since you seem so familiar with tech specs for chest freezers, you should be well aware that they are designed to run 80-90% of the time when in stock configuration and in normal use to store frozen foods. They are designed this way to reduce energy use, since so much energy is required at compressor start up. Take a look at the numerous stories of people who have converted chest freezers into super efficient refrigerators by adding an external thermostat set at ~36°-40°F (sound familiar?). Many of these people use kill-a-watt meters to record the energy usage, and they show that the freezer only runs once every couple of hours, and averages ~90 seconds of run time out of every hour, which is only 2.5% of the time. With this in mind, is it really so hard to believe that with kegs full of beer which have a larger thermal mass than a fridge of assorted food, and the probe secured to something with some thermal mass, my freezer would run for much longer than 90 seconds at a time, but only a few times a day?

As I said before, your method will work fine, but it will also cycle more than necessary, and require a bit of guesswork/trial and error to get the temperature and hysteresis set correctly. I'm not sure why you continue to argue with these facts, but I'm done repeating myself.