Just trying to think out things for my up coming build. Anyone out there have a HERMs coil in their boil kettle (permanent) that they use as, basically, an immersion chiller? I have a plate chiller right now but am not sure I want to use it anymore. I was thinking about having two HERMs coils. One in the HLT for the traditional heat exchanger and then one in the BK to use as an immersion chiller. Thoughts?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HERMs coil in kettle for chilling?

- Thread starter xsists

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Suthrncomfrt1884

Well-Known Member

I have a permanent HERMS coil built into my HLT. I use this for both heating and cooling. As long as your pump can handle boiling temps, then you should be fine doing this. I just make sure I start pumping my finished wort through the coil while it's still boiling, that way it sanitizes everything in the coil. Then I fill my HLT completely with ice water and let it run it's course. It takes me about 10-15 minutes to cool a 10-12 gallon batch.

I also thought about having a coil in the boil kettle, but in my experience with immersion chillers, they're no fun to clean. If it's permanently mounted in your kettle, it would be even harder to clean.

I also thought about having a coil in the boil kettle, but in my experience with immersion chillers, they're no fun to clean. If it's permanently mounted in your kettle, it would be even harder to clean.

xsists

Well-Known Member

I'm not talking about pumping hot wort anywhere though. Basically the HERMs coil in my BK would be an immersion chiller in which I would connect a hose to it and let cold water go through the coil. That would be the only purpose of the coil, nothing but outside cold water would go into the coil.

How so? It would be CIP just like the rest of the system.

I also thought about having a coil in the boil kettle, but in my experience with immersion chillers, they're no fun to clean. If it's permanently mounted in your kettle, it would be even harder to clean.

How so? It would be CIP just like the rest of the system.

calpyro

Well-Known Member

Just trying to think out things for my up coming build. Anyone out there have a HERMs coil in their boil kettle (permanent) that they use as, basically, an immersion chiller? I have a plate chiller right now but am not sure I want to use it anymore. I was thinking about having two HERMs coils. One in the HLT for the traditional heat exchanger and then one in the BK to use as an immersion chiller. Thoughts?

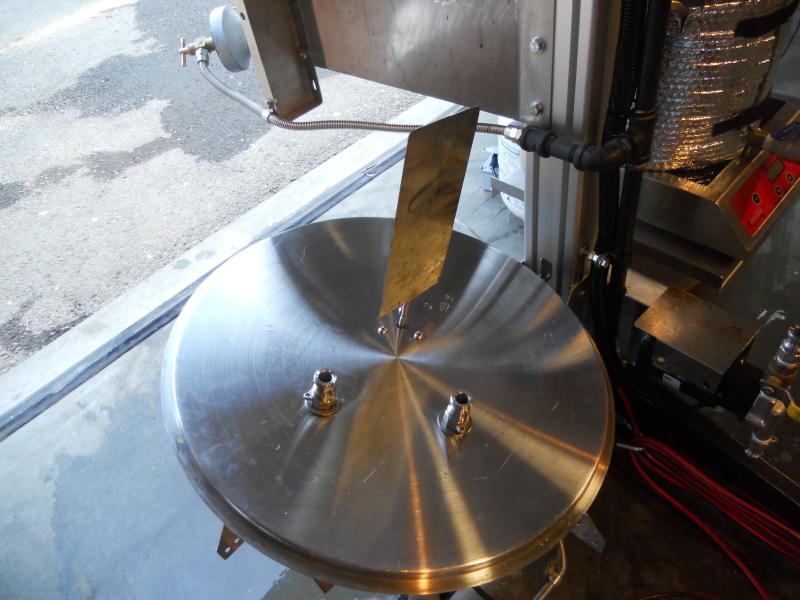

My HERMS coil is attached to the lid of my HLT. I just move it to the kettle to chill the wort. Look closely to to the photo at the top pot. Is is the HLT. You will see a thermometer on the "Out" side of the HERMS/immersion chiller.

It works good.

I used my herms for my last lager. I also have a counterflow chiller and I filled my HLT with ice water and pumped the wort through the counterflow then through the herms to get the temp down to 50F. Worked great and I will probably use it more often to help cool the wort faster.

Stankonia

Well-Known Member

]My HERMS coil is attached to the lid of my HLT. I just move it to the kettle to chill the wort.[/B] Look closely to to the photo at the top pot. Is is the HLT. You will see a thermometer on the "Out" side of the HERMS/immersion chiller.

It works good.

That's a really good idea!

Any chance you can post some pics of how you built that?

I've done exactly what your talking about with a HERMs coil in my HLT and another length of copper coil in my boil kettle permanently built into it. I was using a plate chiller and got a little tired of the complexities of using it, in my system at least, and missed whirl pooling. Put the coil in, pump cold water through with one pump and whirl pool with the other and haven't missed the plate chiller one bit. Much more simple and fool proof for me with identical chill times. Calpyro's lid system looks mighty nice though

I also thought about having a coil in the boil kettle, but in my experience with immersion chillers, they're no fun to clean. If it's permanently mounted in your kettle, it would be even harder to clean.

I've thought about it, too. But I'm less concerned with cleaning the chiller itself than with the difficulty of scrubbing out the kettle with a coil of copper in the way.

xsists

Well-Known Member

I've thought about it, too. But I'm less concerned with cleaning the chiller itself than with the difficulty of scrubbing out the kettle with a coil of copper in the way.

Should be easy enough if you are using regular compression fittings to hold the coil in place.

Should be easy enough if you are using regular compression fittings to hold the coil in place.

Kinda defeats the purpose if you have to take it out every time. And the OP said "permanent."

Brewchitect

Well-Known Member

I used to cool through the HLT coil in an ice bath and it was extremely fast compared to other cooling methods, but adding 10-15$ in ice to every batch got old. I just use an immersion chiller in the BK now. Why would you want it permanent?

builderguy

Well-Known Member

My HERMS coil is attached to the lid of my HLT. I just move it to the kettle to chill the wort. Look closely to to the photo at the top pot. Is is the HLT. You will see a thermometer on the "Out" side of the HERMS/immersion chiller.

It works good.

I do the same...works great. I also put a dip tube in the lid that will allow me to whirlpool/recirculate either the HLT or the wort depending on the stage. This allows me to avoid stratification during the HERMS process and allows me to whirlpool while chilling so I get a nice trub/hop cone in the center of the boil kettle, keeping it out of my fermenter.

calpyro

Well-Known Member

That's a really good idea!

Any chance you can post some pics of how you built that?

The first photos are the top of HERMS/Immersion chiller. The In and Out sides both have male cam lock fittings with a thermometer on the "out" side.

I made two coils each 35', one large and one small. They are situated so the larger sits around the smaller one. They are soldered to two-1/2" copper pipes connected to female cam lock fittings. These fittings connect to male cam lock fittings on underside of the lid.

The coils work in parallel and double the flow.

It really works well and allows me to use the lid for both a HERMS in the HLT and then as an immersion cooler in the kettle. The nice thing is that after running wort though the coil, it needs cleaning and using it as an immersion cooler does just that.

Calpyro,

This is great!

Simple, effective and dual usage, I like it. I'll use the design on my E-HERMS I am planning on building.

This is great!

Simple, effective and dual usage, I like it. I'll use the design on my E-HERMS I am planning on building.

xsists

Well-Known Member

Kinda defeats the purpose if you have to take it out every time. And the OP said "permanent."

I am the OP. I am saying if there is build up and you cannot get to it and need to remove the coil, it should not be hard. I would think a hot PBW soak would clear up everything.

The first photos are the top of HERMS/Immersion chiller. The In and Out sides both have male cam lock fittings with a thermometer on the "out" side.

I made two coils each 35', one large and one small. They are situated so the larger sits around the smaller one. They are soldered to two-1/2" copper pipes connected to female cam lock fittings. These fittings connect to male cam lock fittings on underside of the lid.

The coils work in parallel and double the flow.

It really works well and allows me to use the lid for both a HERMS in the HLT and then as an immersion cooler in the kettle. The nice thing is that after running wort though the coil, it needs cleaning and using it as an immersion cooler does just that.

One question, how do you sanitize the coils before adding them to the wort? Normally, with an IC you stick it in the boil kettle for about 15 minutes, but with the lid DMS could be a problem.

calpyro

Well-Known Member

One question, how do you sanitize the coils before adding them to the wort? Normally, with an IC you stick it in the boil kettle for about 15 minutes, but with the lid DMS could be a problem.

The coil is in the HLT exposed to clean hot water for upwards of two hours, at temps of up to 180+ degrees at mash out. I just move the lid from the HLT to the kettle as an immersion chiller when it is time to chill, not sooner. This exposes it to 212 degrees. No risk for excessive DMS.

I find that exposing a clean HERMS/Immersion coil to extended periods of heat below boiling (in the HLT) is as effective as boiling it. When it is put into the boiling wort it is effectively sterile and the wort (boiling) is not a receptive environment to infection. If you were really concerned, it would be pretty easy to bring the HLT up to boiling (with the HERMS) for as long as you felt was necessary prior to putting it into the kettle.

(Off topic) I am pretty anal about sanitation and use heat for sanitizing everything in my process. You will see a small kettle on the lower right bottom of my sculpture sitting on a 240 Volt, 3500 Watt induction range. It is a Grant that I do decoctions on and use for boiling all of my hoses, parts and pieces.

Back to the point. Also note that my design also seals the wort from the wind and airborne contaminates. It has no gaps or holes for an immersion chiller. If you brew where there is any breeze, my design of an essentially closed system will do a better job of preventing airborne sutff from blowing into the kettle.

calpyro

Well-Known Member

I do the same...works great. I also put a dip tube in the lid that will allow me to whirlpool/recirculate either the HLT or the wort depending on the stage. This allows me to avoid stratification during the HERMS process and allows me to whirlpool while chilling so I get a nice trub/hop cone in the center of the boil kettle, keeping it out of my fermenter.

I am working on a similar design. I am building a stainless steel paddle connected to a geared electric motor: Surplus Center - 64 RPM 120 VAC GEARMOTOR that will be mounted on the lid. The paddle will be centered in the HERMS/Immersion chiller and circulate the liquid past the coil.

I just make sure I start pumping my finished wort through the coil while it's still boiling, that way it sanitizes everything in the coil. Then I fill my HLT completely with ice water and let it run it's course. It takes me about 10-15 minutes to cool a 10-12 gallon batch.

Are you able to achieve a whirlpool when you pump it through your HLT coil?

Suthrncomfrt1884

Well-Known Member

Are you able to achieve a whirlpool when you pump it through your HLT coil?

Yes, if you plan the placement of your return (where the wort goes back into your kettle) then you'll have no problem creating a whirlpool. My return is about 1/3 of the way up from the bottom of the kettle. I'll try to get a picture of it posted. I have a side pickup tube that I customized so it runs right next to the side of the kettle. It causes the wort to create a whirlpool on it's own.

I have a little harder time creating a whirlpool with a 5 gallon batch, but with bigger batches, it works great.

calpyro

Well-Known Member

I am working on a similar design. I am building a stainless steel paddle connected to a geared electric motor: Surplus Center - 64 RPM 120 VAC GEARMOTOR that will be mounted on the lid. The paddle will be centered in the HERMS/Immersion chiller and circulate the liquid past the coil.

Another idea for making a whirlpool or circulation around a HERMS.

I just added the electric motor and paddle to the center of the HERMS/Immersion chiller. I reduced the temp in my kettle today from boiling to 140 degrees in three minutes and 65 degrees in a total of eighteen minutes. I does help to have 50 degree water as well.

Still need to fabricate an enclosure.

Suthrncomfrt1884

Well-Known Member

Another idea for making a whirlpool or circulation around a HERMS.

I just added the electric motor and paddle to the center of the HERMS/Immersion chiller. I reduced the temp in my kettle today from boiling to 140 degrees in three minutes and 65 degrees in a total of eighteen minutes. I does help to have 50 degree water as well.

Still need to fabricate an enclosure.

Very nice! Do you have a thread for the rest of your build? I'd love to take a look at your setup.

CidahMastah

Well-Known Member

- Joined

- Nov 12, 2010

- Messages

- 4,201

- Reaction score

- 46

I am working on a similar design. I am building a stainless steel paddle connected to a geared electric motor: Surplus Center - 64 RPM 120 VAC GEARMOTOR that will be mounted on the lid. The paddle will be centered in the HERMS/Immersion chiller and circulate the liquid past the coil.

Have you tried this out yet (that particular motor)? I am curious because I have been very interested in looking into something similar.

calpyro

Well-Known Member

Have you tried this out yet (that particular motor)? I am curious because I have been very interested in looking into something similar.

Yes, I tested it yesterday on a Robust Porter. It chilled the boiling wort to 140 degrees in three minutes and to 65 degrees in 18 minutes.

CidahMastah

Well-Known Member

- Joined

- Nov 12, 2010

- Messages

- 4,201

- Reaction score

- 46

Yes, I tested it yesterday on a Robust Porter. It chilled the boiling wort to 140 degrees in three minutes and to 65 degrees in 18 minutes.

Very cool - I might have to grab one of those motors. With whirlpooling I can chill pretty darn fast from my well and I can't remember exactly but I get to 130 in 4 mins + or - and pitching temp in about 15mins too.

In particular I would like to add a casual stir motor to the HLT so I don't get heat stratification and my strike temp is actually what the probe reads. Right now I recirculate with my pump... but I would like this part to be done with a motor so I don't ahve to watch it.

Very innovative build you have - really like your designs. Wish I had the same sized HLT and BK, if I did I would be copying your herms coil/chiller lid idea.

dropitlikesitshot

Active Member

Subscribed

subscribed

Similar threads

- Replies

- 2

- Views

- 319

- Replies

- 0

- Views

- 386