d_striker

Well-Known Member

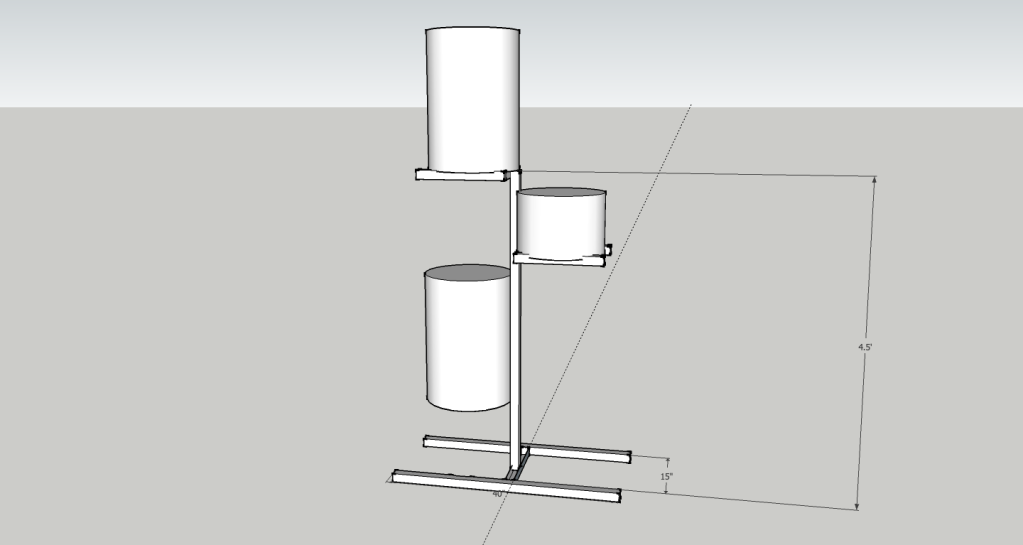

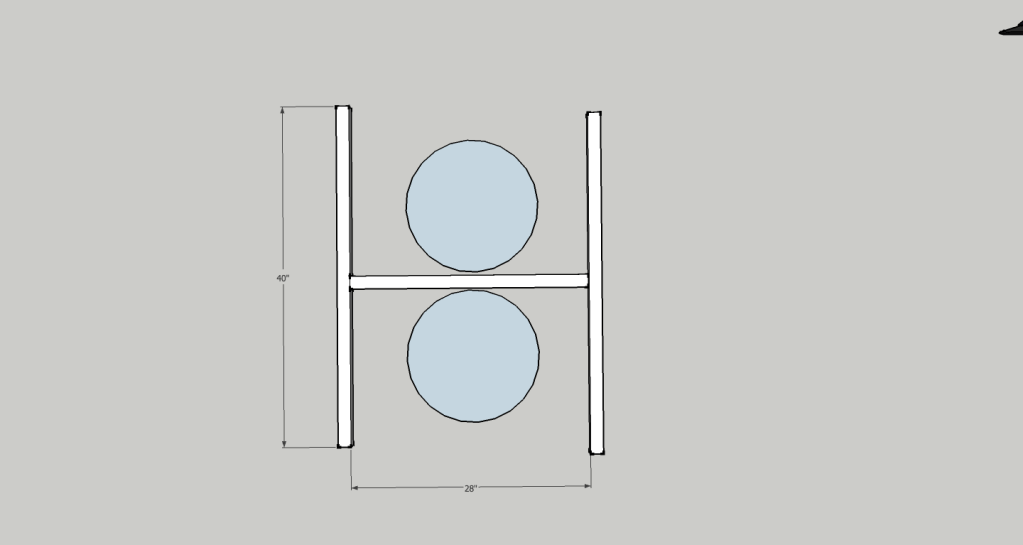

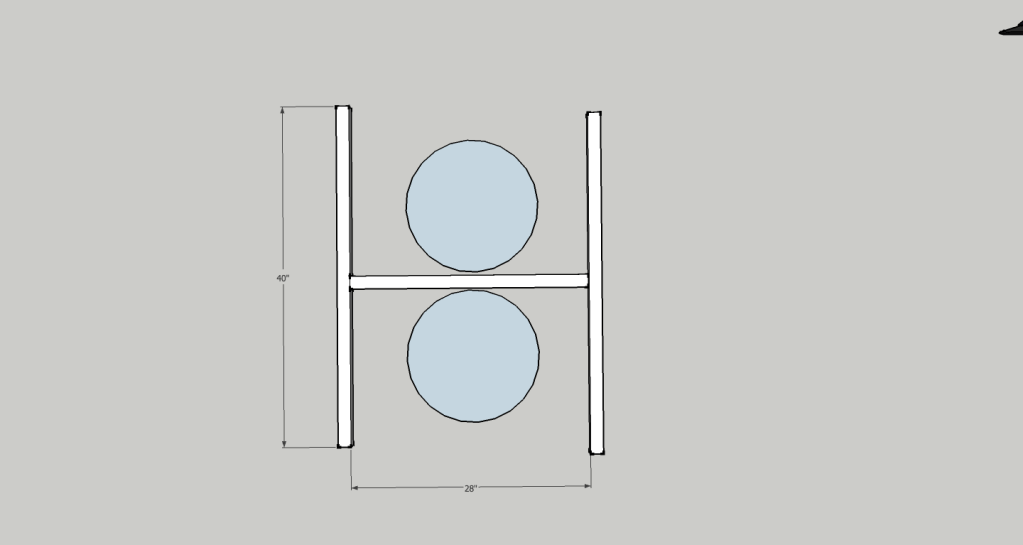

I'm in the process of welding up a 3 tier, vertical brew stand. I was originally planning on making the base 40" x 28". The drawing below is to scale and the circles are keggles.

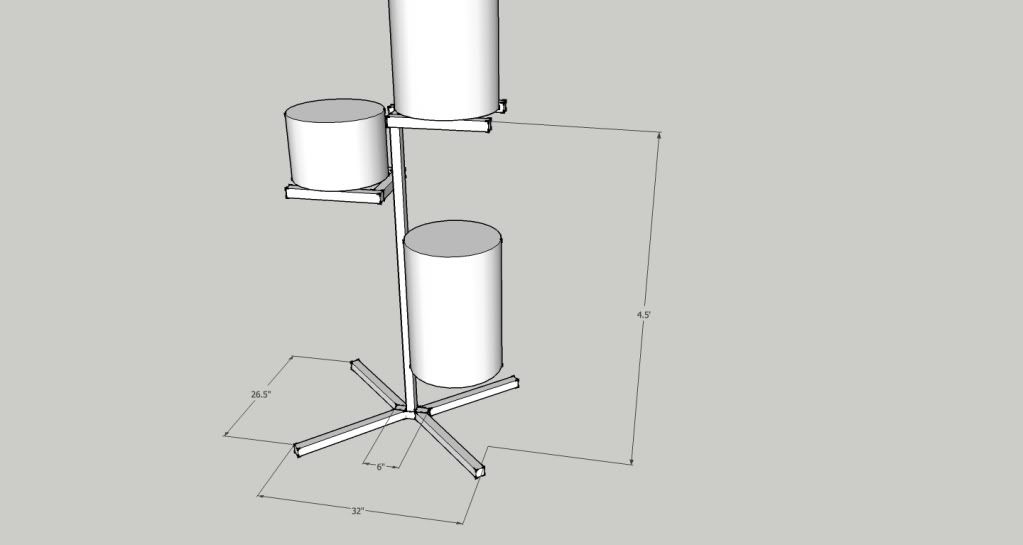

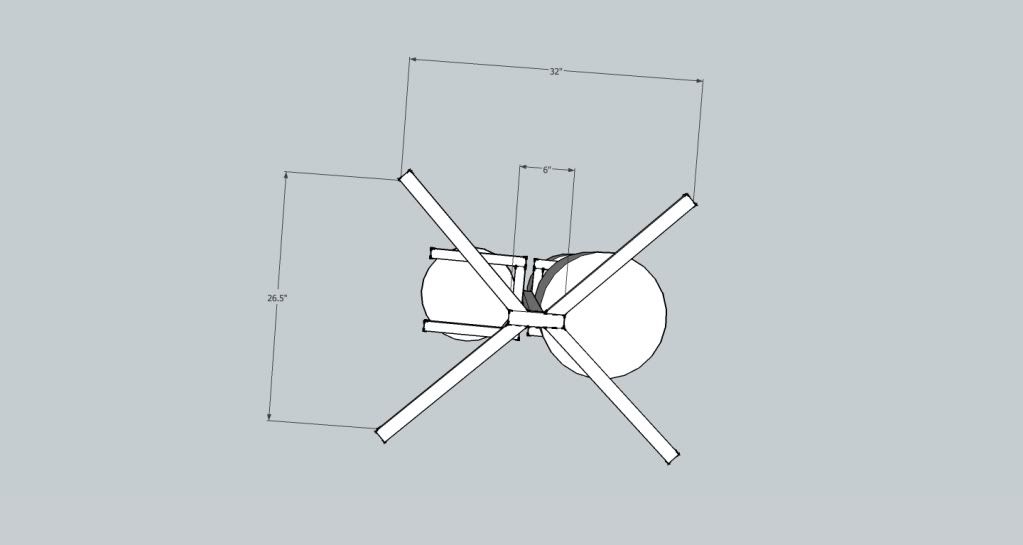

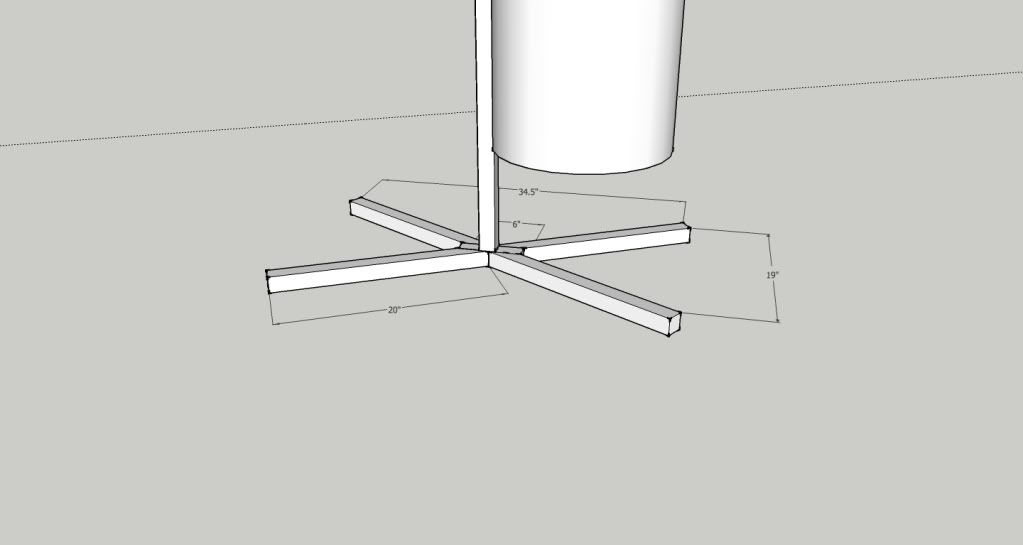

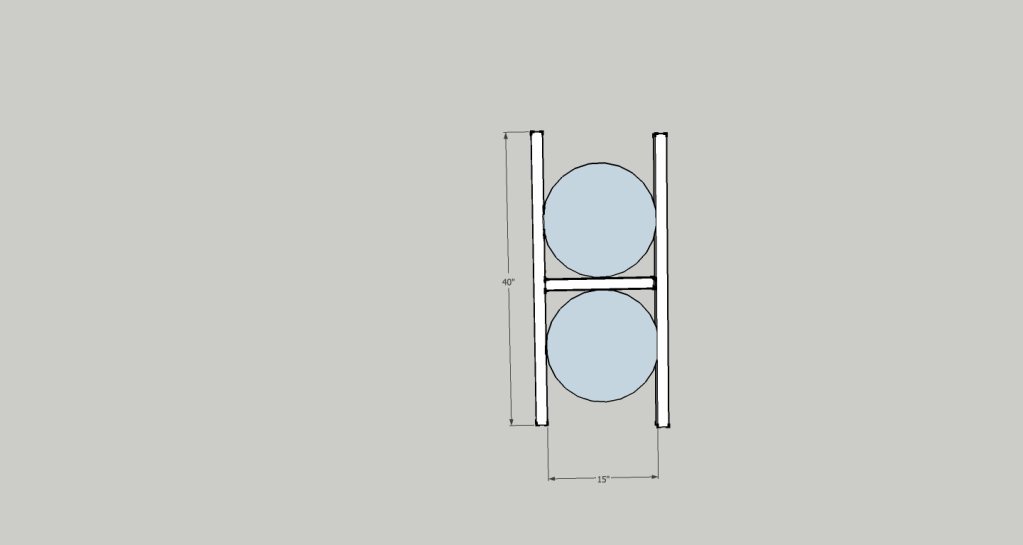

I laid out my steel tubing and I didn't like how big the footprint of this design is. I'm thinking of changing the dimensions to 40" x 15" like the drawing below.

Will this be stable enough? I plan on welding casters to the bottom.

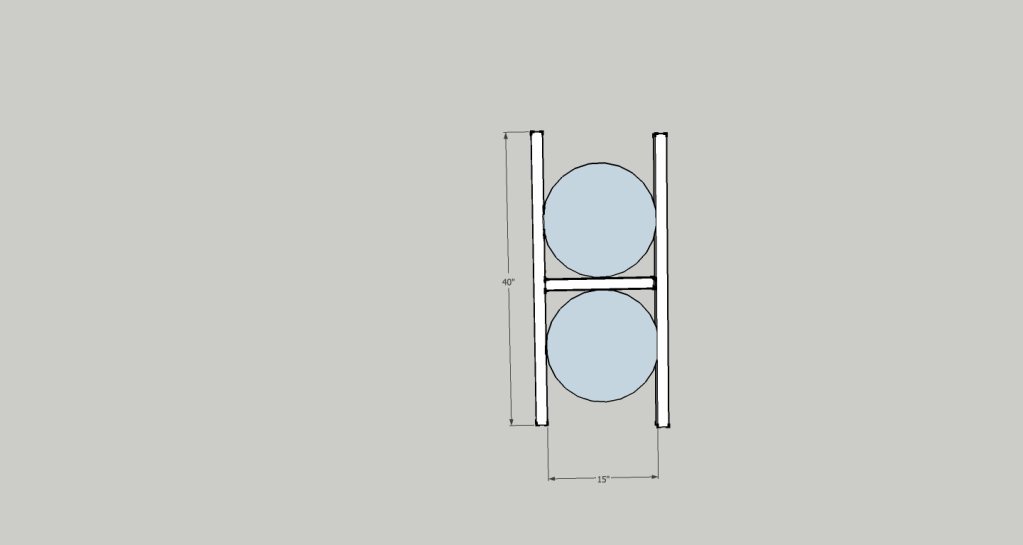

I laid out my steel tubing and I didn't like how big the footprint of this design is. I'm thinking of changing the dimensions to 40" x 15" like the drawing below.

Will this be stable enough? I plan on welding casters to the bottom.