Nothing new or groundbreaking here, but I figured I'd share my first mini-fridge kegerator build. The refrigerator is a Kenmore 94689 4.6 cu ft model. Mine is the model with the black door. It is the same as the stainless steel door Kenmore 94683. It has a slide-out tray for the freezer compartment and a removable freezer door. This makes it easy enough to convert without needing to worry about bending coolant lines as is needed on some other mini-fridges with freezer compartments.

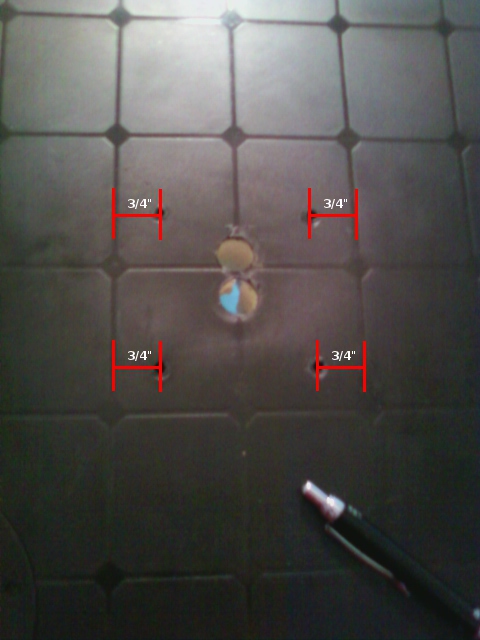

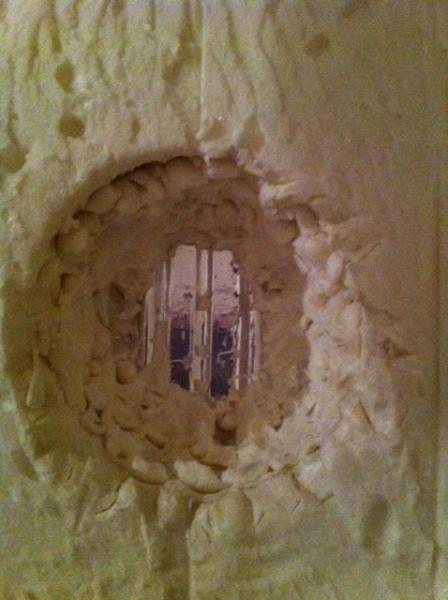

Below is a shot of of the interior after I removed the front door and the freeze compartment. Apparently I forgot to take a picture of it with all the shelves and the freezer compartment still intact. The main problem with this conversion was that the refrigerator is too narrow to fit two ball-lock kegs (it will NOT fit a ball-lock and a pin-lock, let alone two pin-locks). As can be seen in the picture below, there are rails on the side walls that are used to hold the shelves. These will need to be ground down. Also, the temperature control on the right hand side will need to be relocated.

A closer shot of the temp. controller.

Let's get the conversion started. First up is removing the door and cutting out the door shelves. The picture below shows the intact door after it has been removed.

Peeling back the door seal/magnet strip reveals the screws that hold the seal and door shelves in to place.

Here is a picture of the door after the seal and door shelves have been removed.

Two kegs will not fit in the refrigerator with the shelving on the door in place. However, something rigid is required to hold the door seal on the door. I chose to cut out the perimiter of the plastic from the door and use it to mount the seal in place. My first attempt at cutting it out was using a cheap Harbor Freight Dremel knock-off. I don't own a Dremel, and didn't want to spend the money to buy one. For the $8 the HF cut-off tool cost I figured it was worth the gamble. That was a gable I lost. It had very little torque and stalled out quite often while trying to cut through the plastic. My angle grinder and Rotozip would have been too imprecise. I settled on using a jig saw, which made quick work of the cutting. Here is a picture of the frame that was left over after cutting.

This is what the door looks like after reassembling with the plastic frame and the door seal. I suppose I could have used something to increase insulation, but the fit of the kegs was going to be tight enough without sacrificing that small amount of space.

Below is a shot of of the interior after I removed the front door and the freeze compartment. Apparently I forgot to take a picture of it with all the shelves and the freezer compartment still intact. The main problem with this conversion was that the refrigerator is too narrow to fit two ball-lock kegs (it will NOT fit a ball-lock and a pin-lock, let alone two pin-locks). As can be seen in the picture below, there are rails on the side walls that are used to hold the shelves. These will need to be ground down. Also, the temperature control on the right hand side will need to be relocated.

A closer shot of the temp. controller.

Let's get the conversion started. First up is removing the door and cutting out the door shelves. The picture below shows the intact door after it has been removed.

Peeling back the door seal/magnet strip reveals the screws that hold the seal and door shelves in to place.

Here is a picture of the door after the seal and door shelves have been removed.

Two kegs will not fit in the refrigerator with the shelving on the door in place. However, something rigid is required to hold the door seal on the door. I chose to cut out the perimiter of the plastic from the door and use it to mount the seal in place. My first attempt at cutting it out was using a cheap Harbor Freight Dremel knock-off. I don't own a Dremel, and didn't want to spend the money to buy one. For the $8 the HF cut-off tool cost I figured it was worth the gamble. That was a gable I lost. It had very little torque and stalled out quite often while trying to cut through the plastic. My angle grinder and Rotozip would have been too imprecise. I settled on using a jig saw, which made quick work of the cutting. Here is a picture of the frame that was left over after cutting.

This is what the door looks like after reassembling with the plastic frame and the door seal. I suppose I could have used something to increase insulation, but the fit of the kegs was going to be tight enough without sacrificing that small amount of space.