thomcat333

Well-Known Member

For the others out there with the Polarware brew pot (mine is 40qt), are you getting decent mash efficiencies with the Polarware false bottom?

I have consistently gotten lower yields than I'd like using the false bottom (~67-70%), and I'm guessing it's because of the large space under the false bottom (~1 gallon or so) and the outlet being on one side. So...

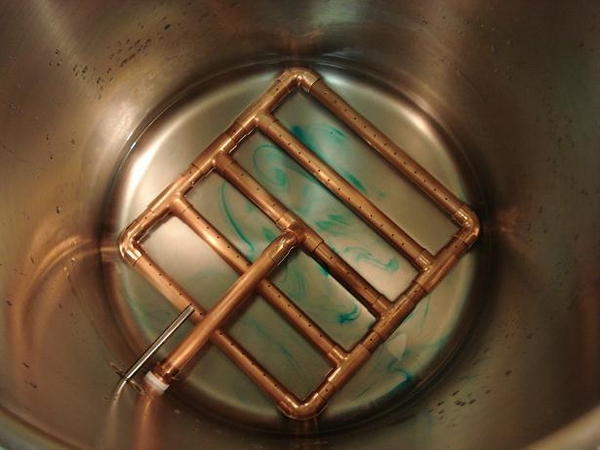

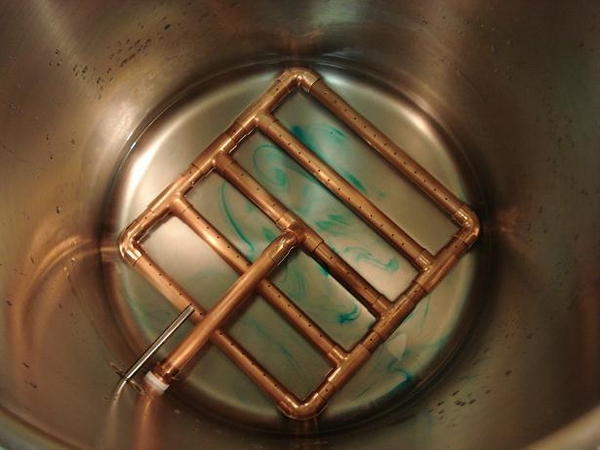

I said screw it and used my day off to build a copper manifold. It should give a better flow distribution. This is how it came out. I dropped a bit of food coloring in some water to see how it pulled. So far so good... no major bias in flow.

- Andy

I have consistently gotten lower yields than I'd like using the false bottom (~67-70%), and I'm guessing it's because of the large space under the false bottom (~1 gallon or so) and the outlet being on one side. So...

I said screw it and used my day off to build a copper manifold. It should give a better flow distribution. This is how it came out. I dropped a bit of food coloring in some water to see how it pulled. So far so good... no major bias in flow.

- Andy