jbsengineer

Well-Known Member

I recently built an eBrewery. I followed most of Kal's plans but what I didn't follow was the pumps. I went with the latest edition of the Chugger Stainless Steel inline pumps. After two batches I found my flow rate in my mash/tun a bit subpar. Some research led me to believe that the flow should be a bit stronger and my ramp up times for mash-in and mash-out should be better. Also, I found that between the two Chugger pumps (Water & Wort) my Wort pump was anywhere from 5-10% slower.

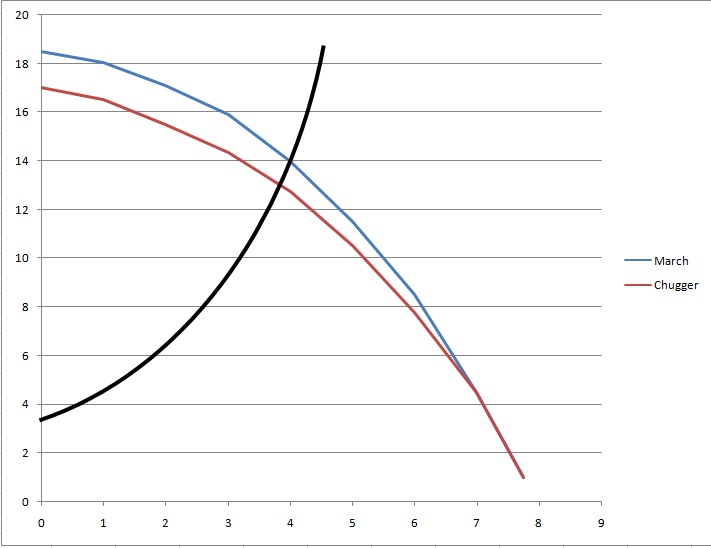

So I ordered an 815-PL for some comparison testing. My testing showed the 815-PL beat the Chugger each time. Not by a great margin but enough to make a difference in my setup.

According to the Chugger website they are rated at 7GPM with an 18 feet maximum head. According to the March website, the 815-PL is also rated at 7GPM with a 18 feet maximum head.

I performed these tests against my "better" Chugger pump. (Again is some previous testing I found one pump to outperform the other by 5%-10% depending on the test)

I would give the results a +/- 2 seconds for accuracy. I repeated a few of them to get my testing down.

No Coil Test Details:

1) Filled HLT with water

2) Pumped 3.5 gallons into Mash/Tun

3) Connected 2x4' hoses

4) One connected from the HLT into the pump inlet

5) The outlet connected directly to the connection on the top of the Mash/Tun (The inlet on the mash/tun is connected to a 5' long piece of hose. I placed the outlet of the host on the bottle of the kettle (under 3.5Gallons of water). I did in order to add some resistence in the pumping. During my mashing process the host is under 1 inch or so of wort.

6) Prime pump and verify no air in order for a consistent test

7) Close pump valve and turn pump on

8) Open valve and start timer

9) Let the pump move 5 gallons of water into the Mash/Tun and stop timer.

10) Reset

The results between the two pumps. The test consisted of pumping 5 gallons of water directly without the 50' coil inline:

March 815-PL: 1min:17sec

Chugger: 1min:30sec

With Coil Test Details:

1) Filled HLT with water

2) Pumped 3.5 gallons into Mash/Tun

3) Connected 3x4' hoses

4) One connected from the HLT into the pump inlet

5) The outlet connected to the bottom inlet of the HERMs coil

6) The outlet of the HERMs coil is connected to the inlet of the Mash/Tun

7) Prime pump and verify no air in order for a consistent test

8) Close pump valve and turn pump on

9) Open valve and start timer

10) Let the pump move 5 gallons of water into the Mash/Tun and stop timer.

11) Reset

The results between the two pumps. The test consisted of pumping 5 gallons of water with a 50' HERMs coil inline:

March 815-PL: 2min:48sec

Chugger: 3min:10sec

In summary:

The Chugger performed at 85.5% of the speed of the March in the no coil test and 88.4% with the coil. Almost linear. The Chugger pumps ~.5 gallon less per 5 gallons. Again, as this was tested with my better performing Chugger pump, I'm a little curious to what these would numbers would look like against the other one. In my original testing I found a 5%-10% difference in performance.

I'm a bit dissapointed at the performance with the Chugger. I plan to keep the March and use the Chugger as a spare.

As an extra tidbit I also found the March to be better with priming and avoiding cavitating, hands down. It was also quieter.

So I ordered an 815-PL for some comparison testing. My testing showed the 815-PL beat the Chugger each time. Not by a great margin but enough to make a difference in my setup.

According to the Chugger website they are rated at 7GPM with an 18 feet maximum head. According to the March website, the 815-PL is also rated at 7GPM with a 18 feet maximum head.

I performed these tests against my "better" Chugger pump. (Again is some previous testing I found one pump to outperform the other by 5%-10% depending on the test)

I would give the results a +/- 2 seconds for accuracy. I repeated a few of them to get my testing down.

No Coil Test Details:

1) Filled HLT with water

2) Pumped 3.5 gallons into Mash/Tun

3) Connected 2x4' hoses

4) One connected from the HLT into the pump inlet

5) The outlet connected directly to the connection on the top of the Mash/Tun (The inlet on the mash/tun is connected to a 5' long piece of hose. I placed the outlet of the host on the bottle of the kettle (under 3.5Gallons of water). I did in order to add some resistence in the pumping. During my mashing process the host is under 1 inch or so of wort.

6) Prime pump and verify no air in order for a consistent test

7) Close pump valve and turn pump on

8) Open valve and start timer

9) Let the pump move 5 gallons of water into the Mash/Tun and stop timer.

10) Reset

The results between the two pumps. The test consisted of pumping 5 gallons of water directly without the 50' coil inline:

March 815-PL: 1min:17sec

Chugger: 1min:30sec

With Coil Test Details:

1) Filled HLT with water

2) Pumped 3.5 gallons into Mash/Tun

3) Connected 3x4' hoses

4) One connected from the HLT into the pump inlet

5) The outlet connected to the bottom inlet of the HERMs coil

6) The outlet of the HERMs coil is connected to the inlet of the Mash/Tun

7) Prime pump and verify no air in order for a consistent test

8) Close pump valve and turn pump on

9) Open valve and start timer

10) Let the pump move 5 gallons of water into the Mash/Tun and stop timer.

11) Reset

The results between the two pumps. The test consisted of pumping 5 gallons of water with a 50' HERMs coil inline:

March 815-PL: 2min:48sec

Chugger: 3min:10sec

In summary:

The Chugger performed at 85.5% of the speed of the March in the no coil test and 88.4% with the coil. Almost linear. The Chugger pumps ~.5 gallon less per 5 gallons. Again, as this was tested with my better performing Chugger pump, I'm a little curious to what these would numbers would look like against the other one. In my original testing I found a 5%-10% difference in performance.

I'm a bit dissapointed at the performance with the Chugger. I plan to keep the March and use the Chugger as a spare.

As an extra tidbit I also found the March to be better with priming and avoiding cavitating, hands down. It was also quieter.