Well this project took on a life of it's own! What started out as the desire to get back in to grain brewing evolved in to what you see here!  First time I've ever welded and am very happy with the way it turned out :rockin:. My original intent was to make it from SS, but not being familiar with welding and the fear of ruining $300+ in SS lead me to use regular steel, but as a compromise I figured I'd put a cool paint job on it!

First time I've ever welded and am very happy with the way it turned out :rockin:. My original intent was to make it from SS, but not being familiar with welding and the fear of ruining $300+ in SS lead me to use regular steel, but as a compromise I figured I'd put a cool paint job on it!

I'd like to thank the HBT community for all the ideas and inspiration and all the HBT vendors and supporters, almost everything was built with their products:

Tri-Clovers from Swagman - Beautiful fittings and his service was over the top!

Bargain Fittings for many of the compression fittings and weldless valves

Chugger Pumps for the pumps

More Beer for so many things - kettles, chillers, fittings, hoses, attire

and

Brewer's hardware for the burner shields and stir plate.

As for the build, it's kind of a Brutus 10 but modified to meet the requirements of a 5 gallon system.

Steel is 1.5" square tube 14GA and if very robust. I don't see anyway that this thing would fail under a full load.

Horizontal pieces are what the called "hammered" to give the project a little visual appeal and vertical pieces are standard square tube.

One of my goals was to keep everything contained within the frame. I didn't want gas lines, burners, or any misc hanging outside the frame. I couldn't accomplish that with everything (pumps) but other than that everything is contained within the frame.

On a test run I didn't have the risers on top of the frame, the kettle sat directly on the frame. This created a couple concerns. It seemed like they burners could not really breath (although there were openings in the corners), I also observed the flames wrapping around the frame and I thought there might be some thermal stratification preventing me from getting the full efficiency from the burners. To address that, I welded some angle iron on to the top of the frame. This gave the burners enough room to breath and helped heat the kettles.

Enjoy and please PM me if you have any questions!

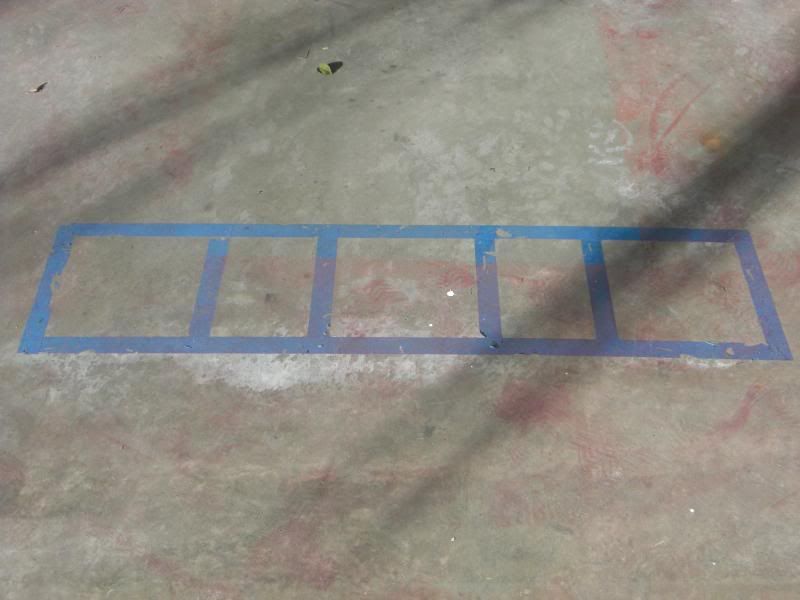

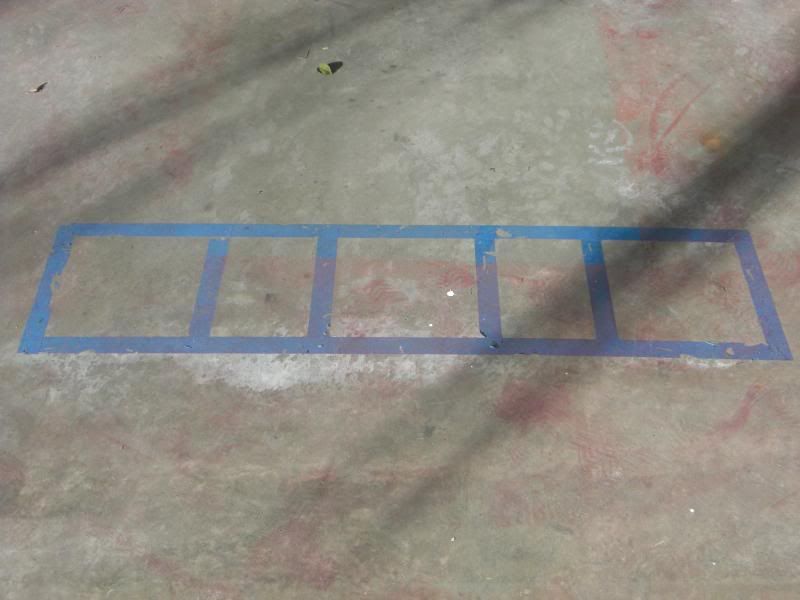

The project stated as a taped template on my garage floor!

Finished project with kettles, pumps and hoses. Still need to do the electrical, but that will be easy

Pumps

I'd like to thank the HBT community for all the ideas and inspiration and all the HBT vendors and supporters, almost everything was built with their products:

Tri-Clovers from Swagman - Beautiful fittings and his service was over the top!

Bargain Fittings for many of the compression fittings and weldless valves

Chugger Pumps for the pumps

More Beer for so many things - kettles, chillers, fittings, hoses, attire

and

Brewer's hardware for the burner shields and stir plate.

As for the build, it's kind of a Brutus 10 but modified to meet the requirements of a 5 gallon system.

Steel is 1.5" square tube 14GA and if very robust. I don't see anyway that this thing would fail under a full load.

Horizontal pieces are what the called "hammered" to give the project a little visual appeal and vertical pieces are standard square tube.

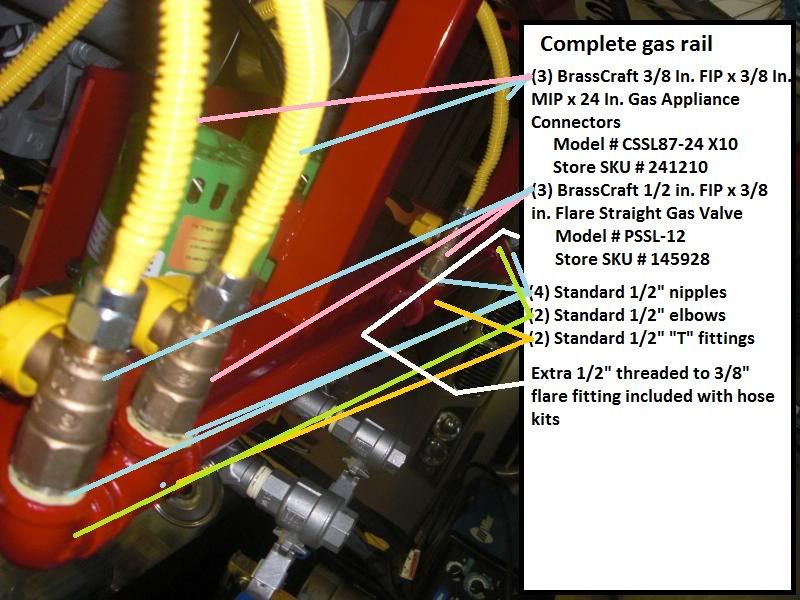

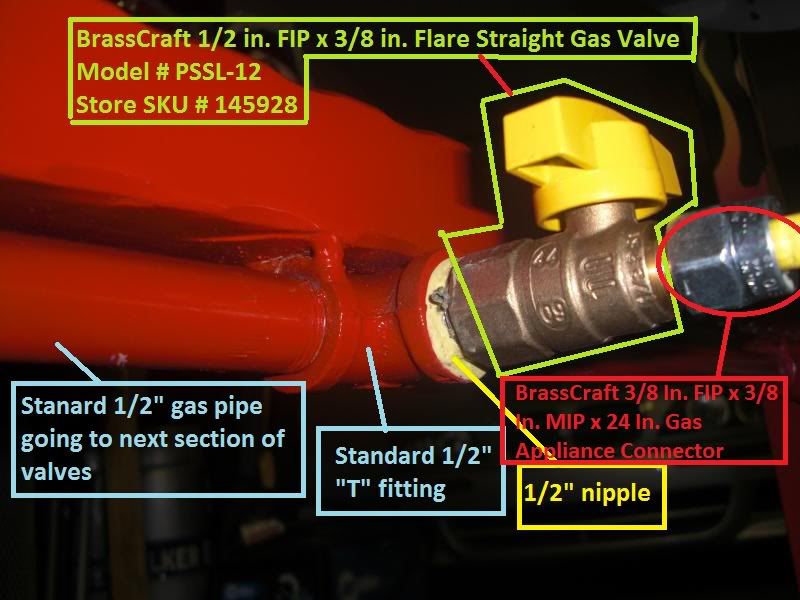

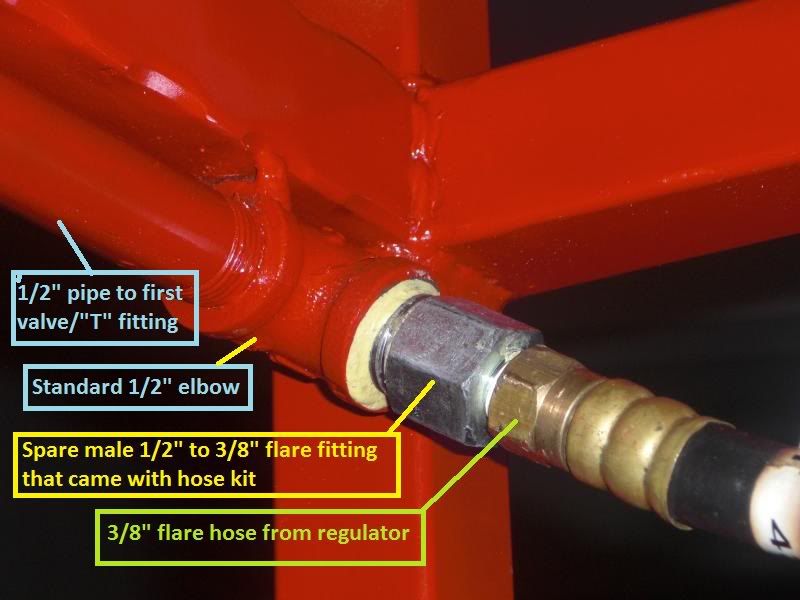

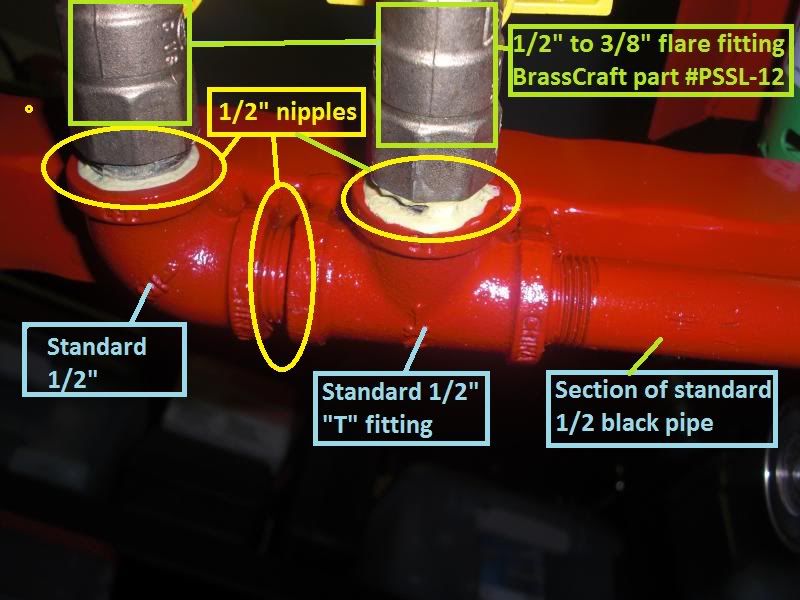

One of my goals was to keep everything contained within the frame. I didn't want gas lines, burners, or any misc hanging outside the frame. I couldn't accomplish that with everything (pumps) but other than that everything is contained within the frame.

On a test run I didn't have the risers on top of the frame, the kettle sat directly on the frame. This created a couple concerns. It seemed like they burners could not really breath (although there were openings in the corners), I also observed the flames wrapping around the frame and I thought there might be some thermal stratification preventing me from getting the full efficiency from the burners. To address that, I welded some angle iron on to the top of the frame. This gave the burners enough room to breath and helped heat the kettles.

Enjoy and please PM me if you have any questions!

The project stated as a taped template on my garage floor!

Finished project with kettles, pumps and hoses. Still need to do the electrical, but that will be easy

Pumps