mhermetz

Well-Known Member

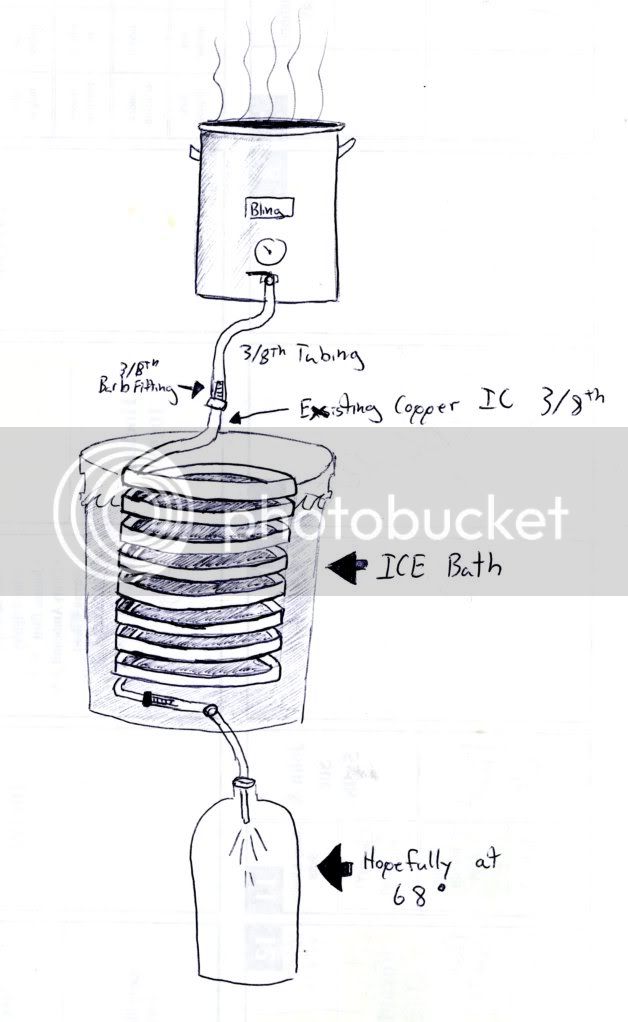

I think I'd rather do this then create a CFC, as long as it will work ofcourse.

The reason being I have my old bottling bucket sitting around; I never used it since I keg. Since it's taking up space anyway, I might as well put it to good use.

I will still need to re-coil my Immersion chiller to fit the bucket. Right now the coils are really close together, but i figure for the wort to effectively cool off they shouldn't be close together using this method. I want as much cold water surrounding the copper piping as possible.

Another reason, I think this will save water.

Quick question though. How do you assemble quick disconnects? I think it would be a good idea to have one on the hose connecting the BK to the chiller.