Crazy8

Well-Known Member

Keep us posted if you a version and anything you change

I brewed up 3 gallons of the "Signature" and 2 gallons of the "Honey Badger". I made some changes, but mostly minor. Here they are:

Signature - (3 gallons)

12qts - Water

36oz - Honey

3/8cp - Sarsaparilla

3/8cp - Sassafras

------------------------------

3cp - Brown Sugar

1/2cp - Vanilla Flavoring

3/8tsp - Nutmeg

4oz - Maltodextrine

1/8tsp Yeast/gallon

NOTE: I took out 3/8tsp salt and 3/8cp of raisins. I'll see how this batch ends up. I feel those wont make a big impact.

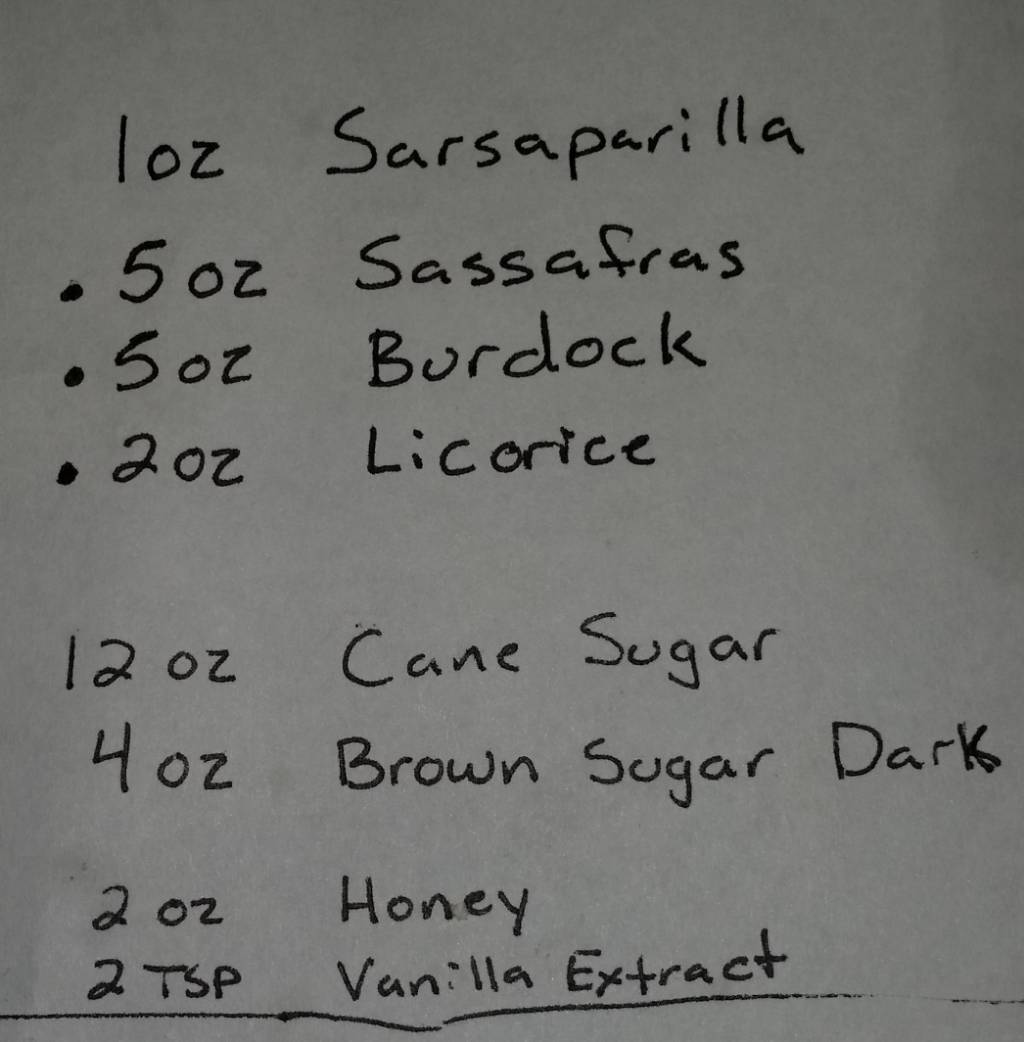

Honey Badger - (2 gallons)

8qts - Water

24oz - Honey

1oz - Sassafras

-----------------------------

1cp - Vanilla

2.6oz - Maltodextrine

1lb - Brown Sugar

1/8tsp - Yeast/gallon

NOTE: Other than altering the amounts of ingredients from a 3 gallon recipe, down to a 2 gallon recipe, nothing has really changed. The one big thing is that I noticed between the 2 recipes, the honey ratio in the Signature, was at a higher ratio than Honey Badger. This just didn't feel right. I mean, with a name like "Honey Badger" it should have at least the same ratio of honey. What I did, was, even though I cut out 1 gallon from the recipe, I kept the 24oz of honey that the 3 gallon recipe calls for. That puts me at 12oz/gallon, which is exactly what the Signature is at. However, Honey Badger has fewer ingredients, so I am hoping that may help in bringing that honey flavor to the front more.

NOTE NOTE: Up above, everything that is above the dashed line went into the pot and was boiled. Everything below the dashed line was put in right at the end after dumping the brew into the bucket. I can't wait to see how it all comes out.