cyberbackpacker

Well-Known Member

I finally got around to making a milling station for my 3 roller Crankandstein mill.

Total Cost: $4.00

I had some old MDF scraps laying around, and I am using an old fermentation bucket as the base. The only thing I had to buy was the 5 gallon Culligan bottle.

Pics:

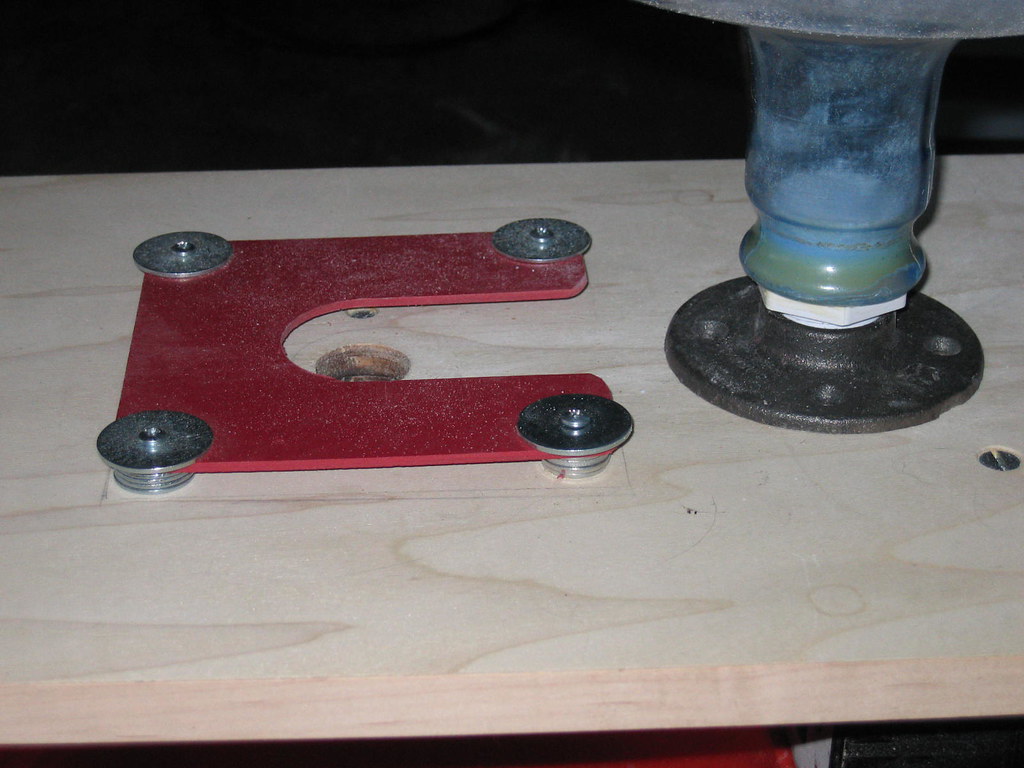

Mill mounted to sheet of MDF.

Slot over rollers cut out, and hole drilled in side of bucket with plastic "ribs" removed from bucket in that area to allow for the drill chuck to fit and spin freely.

Top view. Board was left long to act as a counter weight for when the drill is attached to the mill.

Box that the Culligan water bottle hopper will fit in.

to be continued...

Total Cost: $4.00

I had some old MDF scraps laying around, and I am using an old fermentation bucket as the base. The only thing I had to buy was the 5 gallon Culligan bottle.

Pics:

Mill mounted to sheet of MDF.

Slot over rollers cut out, and hole drilled in side of bucket with plastic "ribs" removed from bucket in that area to allow for the drill chuck to fit and spin freely.

Top view. Board was left long to act as a counter weight for when the drill is attached to the mill.

Box that the Culligan water bottle hopper will fit in.

to be continued...

That red stuff is a piece of sheet vinyl I had laying around, but a piece of Masonite would probably work just as well.

That red stuff is a piece of sheet vinyl I had laying around, but a piece of Masonite would probably work just as well.