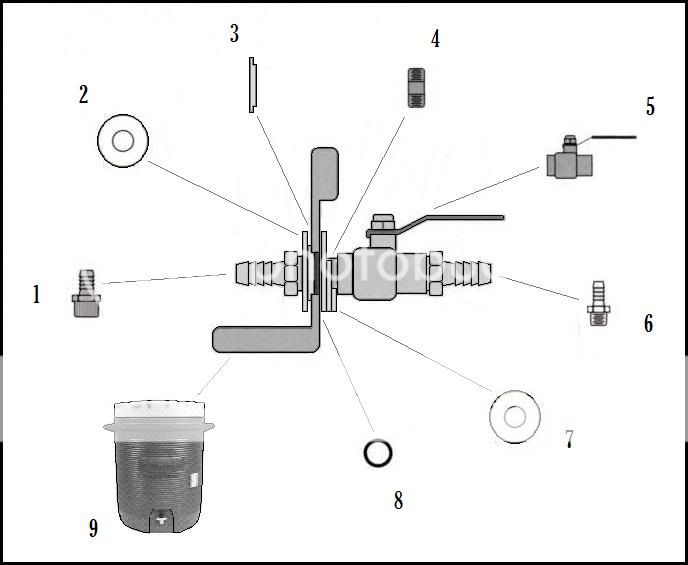

I have started to make a cooler mash tun. Based on what I was able to buy today at several random stores, I have the following:

2 o rings

1 ball valve

1 nipple

2 washers

(can't remember the name, but we will call it piece X) - 1 piece for the inside of the cooler that screws on the end of the nipple

I attempted to assemble it in the following manner from inside to outside:

Piece X, washer, o-ring, nipple, o-ring, washer, ball valve

It drips through the outside near the o ring. If anyone's confused by this I can upload pictures later.

2 o rings

1 ball valve

1 nipple

2 washers

(can't remember the name, but we will call it piece X) - 1 piece for the inside of the cooler that screws on the end of the nipple

I attempted to assemble it in the following manner from inside to outside:

Piece X, washer, o-ring, nipple, o-ring, washer, ball valve

It drips through the outside near the o ring. If anyone's confused by this I can upload pictures later.