I'm building a dedicated brew space in my basement cold room, and I figured I would document/photograph the process, hopefully to help others who are thinking of a similar setup.

Also it should be noted that I'm not the handiest guy in the world, so if I can do this, it means pretty much anyone can.

Goals:

- Brew in place

- Clean in place

- Replace propane burner with an Electric setup

- storage (all gear in one area instead of all over the basement and garage)

- portability -- if I move, I want to be able to take this stuff with me.

- Minimal modifications to the room itself (with the exception being the shelving I want to install - that will be permanent)

-----------------------------------------------

Budget: <$1000 all in. I don't count my time.

To contrast, my current process involves pulling everything out of the basement/garage, my mashing is done in the kitchen. I feel like half my brew day is spent dragging equipment and buckets of wort around the house.

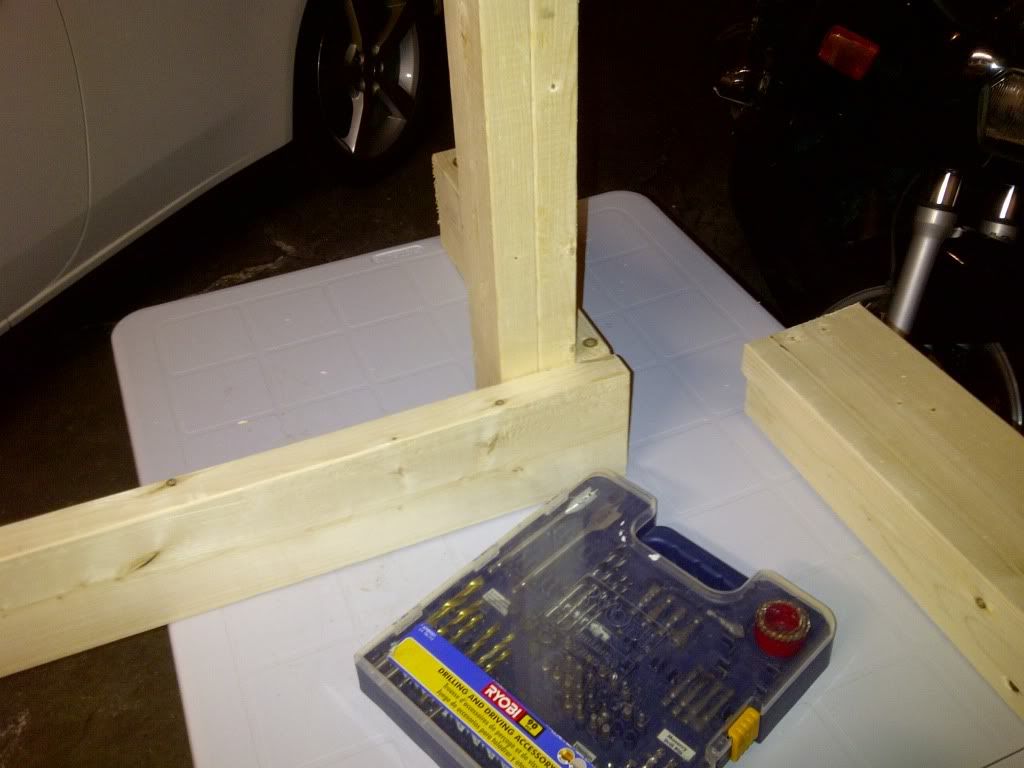

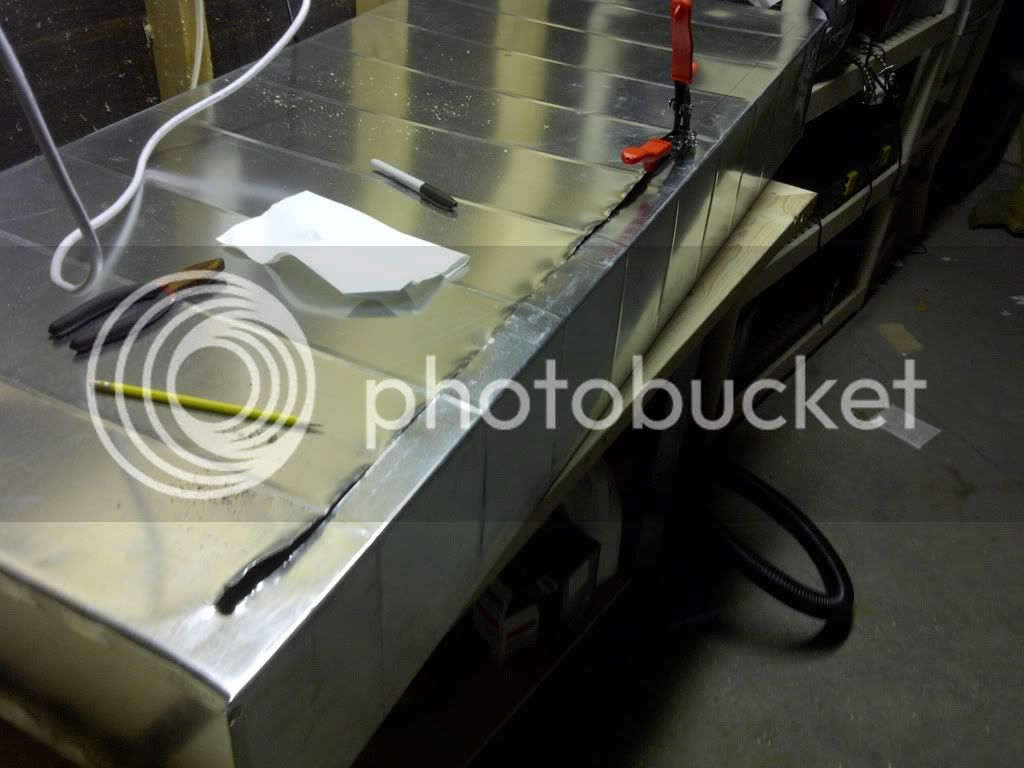

The cold room had been filled with mostly boxes and random storage. I cleaned out the room, and started thinking of a good layout. The room is 7' x 10'. Theres a sump pump in the corner, which is pretty unsightly and will be covered/hidden by the brew stand.

On the other side of the room, I'd like to build in some shelving to keep all my brewing related stuff in one area (as well as other legit cold room stuff )

)

Here's a high level plan for the room:

Above the brew stand I'll be putting in some ventilation. there are a couple 4" existing vents for the cold room, one is partially blocked by the sump pump, one is free, but isn't very round.. I'll have to run a 3" pipe through the 4" hole for venting steam outdoors.

I've got some work done already, more pics coming to show progress!! :rockin:

RUNNING TOTAL: $0

Also it should be noted that I'm not the handiest guy in the world, so if I can do this, it means pretty much anyone can.

Goals:

- Brew in place

- Clean in place

- Replace propane burner with an Electric setup

- storage (all gear in one area instead of all over the basement and garage)

- portability -- if I move, I want to be able to take this stuff with me.

- Minimal modifications to the room itself (with the exception being the shelving I want to install - that will be permanent)

-----------------------------------------------

Budget: <$1000 all in. I don't count my time.

To contrast, my current process involves pulling everything out of the basement/garage, my mashing is done in the kitchen. I feel like half my brew day is spent dragging equipment and buckets of wort around the house.

The cold room had been filled with mostly boxes and random storage. I cleaned out the room, and started thinking of a good layout. The room is 7' x 10'. Theres a sump pump in the corner, which is pretty unsightly and will be covered/hidden by the brew stand.

On the other side of the room, I'd like to build in some shelving to keep all my brewing related stuff in one area (as well as other legit cold room stuff

Here's a high level plan for the room:

Above the brew stand I'll be putting in some ventilation. there are a couple 4" existing vents for the cold room, one is partially blocked by the sump pump, one is free, but isn't very round.. I'll have to run a 3" pipe through the 4" hole for venting steam outdoors.

I've got some work done already, more pics coming to show progress!! :rockin:

RUNNING TOTAL: $0