covered95

Well-Known Member

Can someone point me to a thread that explains the pros and cons of batch sparging vs fly sparging? I have looked, but can not find. If it doesn't exist could someone give me some info? Thanks

Waldo said:I guess I don't understand how you could only get 50% to 60% batch sparging and jump to 85% fly sparging, as we all know strange things happen.

Both processes simply rinse sugars from the grain, batch sparging is easier uses less equipment and is faster. Fly sparging uses more equipment and if done properly takes longer, you may see higher efficiency with fly sparging but there is no guarantee, some claim fly sparging produces better wort again there is no proof of this.

Bobby_M said:Yeah, you calculated your efficiency incorrectly apparently. I too agree that the simplest thing you can do is use sparge water near 185-190F as mentioned above. I know, I know, it's breaking the theoretical tannin extraction limit of 170. However, it equalizes with the 150F grain temp very quickly somewhere in the mid 160's if you stir it relatively quickly. You could easily jump 10% in efficiency doing this.

DesertBrew said:My best guess on this is full conversion hasn't occured and the batch sparge shut the door on conversion (especilally if doing a mash out). I fly sparge but don't mash out. My fly water is usually around 170 so as it sprinkles on it's probably retaining about the same temp as the rest so I'm probably doing more like a 2 hour conversion with this approach.

Waldo said:You'd be surprised just how fast conversion happens, I've experimented with mashes as short as 20 minutes and have had good results but of course the magic number for me is still 60 minutes.

I think the 3 most important things in batch sparging are.

1. Crush, you can't rely on the LHBS people are always messing with the settings on those mills, best to buy your own mill.

2. stir for at least 2 minutes before each sparge to get the sugars in solution.

3. Only wait a couple of minutes after stirring before vorlaufing and the drain as fast as you can.

Why do you want to drain as fast as you can?

Joe Dragon said:Thank you Trub. How close should the pre-boil (6.5 gallons) gravity be to the final (5.5 gallon) gravity? I would think 18% less or so. This weekend Im brewing a Guiness clone from Zymurgy but instead of 6 pounds of base malt Im going with 7. I figger its worth the $1.97 for another pound of 2-row.

Concept

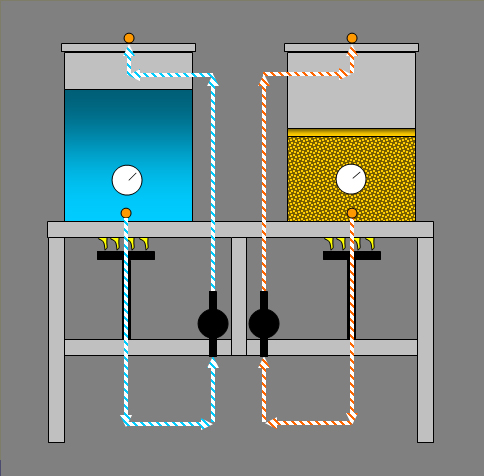

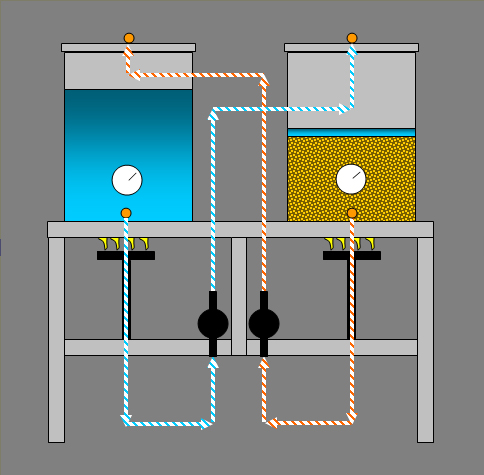

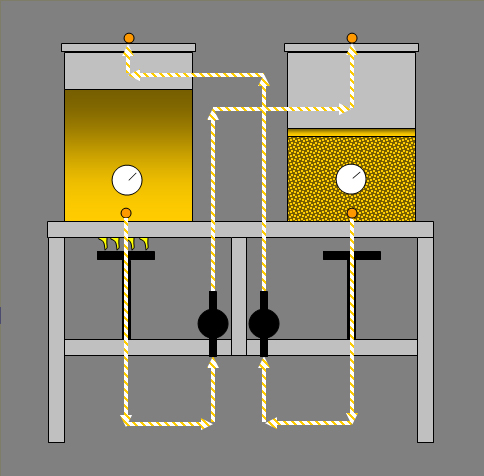

So what’s in a concept? Brewing with only two pots is relatively easy; actually easier, as I will explain. Too there are many benefits to this method I have found. This two pot method may not be cheaper, as in any single tier system a pump or two is required, and in a two tier, at least one pump will be required using this method. Basically as you can see in the diagrams, the system utilizes cross recirculation. After the normal mash resting period and the HLT/kettle is heated to 168/170 mash-out temp, the flow rates can be set in the mash tun and the HLT/kettle. The flow rates in each are set to a very slow trickle, each recirculating back to itself at this point. Once this rate is constant between the two, you can simply switch lids. Now the HLT/kettle water is flowing gently over the grains in the mash tun, out of the mash tun and back to the very same supply from the HLT/kettle. The HLT/kettle water will slowly become the wort. In the end, all will equalize between the two pots and all will be one in harmony! Recirculate the system until you are satisfied that the OG is the same anywhere in the system; HLT/kettle or mash tun, it will eventually equalize. In my system, 45 minutes is plenty of time to accomplish equilibrium and planet alignment.

Benefits…

Indeed your efficiency will be slightly less than fly sparging utilizing this method. Not really a benefit per say, but no more or so less efficiency than batch sparging in general. I have bumped my efficiency down from my normal fly sparging using traditional methods of 78% back to about 74% or so. This is no real deal to me anyway as anyone who knows Lonnie Mac, knows that I can give a rat’s butt about efficiency! This ain’t a grain race here; it’s about beer man! I collect the sugars that my recipe needs and no more. As far as PH, as we know during a long extended fly sparge the PH will rise. Much over 6.0 and we start to see astringency. This method utilizes the benefit of batch sparging in that respect. Likewise, I won’t be stripping my grain of every sugar molecule as this is not my intention. Let’s face it. I am a fly sparger from way back; pushing the limit, I have over-sparged a time or two like most have or will at some point. This method combines the two traditional sparge methods, in essence, a culmination, giving us a continuous batch sparge without the work involved, continuous natural grain bed filtration, slams the hammer down on PH and over-sparge astringency problems, heating of the wort can begin sooner too, in effect increasing efficiency during final recirculation sparging, the benefit list goes on… And too, the smaller footprint of a two pot system may allow patio and small space brewers a better option.

This illustration shows Brutus 20 all set up at the beginning of the brew day. Pumps recirculating among themselves, HLT/kettle water heating to 170 and the Mash maintaining my preset mash temp for 1 hour. Both are recirculating VERY slowly and each flow rate is matched.

After an hour long mash, HLT/kettle water heated, the lids are switched to allow the HLT/kettle water to gently flow into the mash tun, and the mash to gently flow into the HLT/kettle.

This diagram represents a 1 hour recirculation sparge, when ALL things are at total equilibrium and all OG readings are the same no matter where you take it in the system.

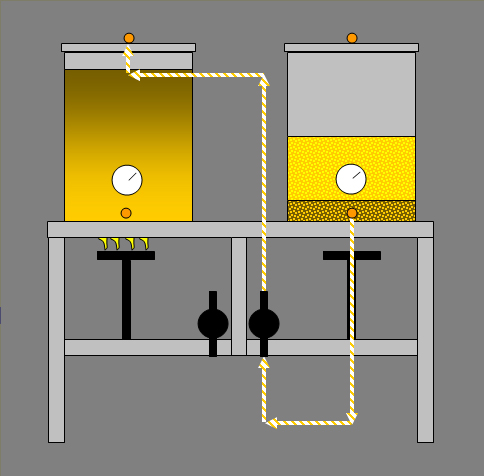

After equilibrium, the remaining sugars can be pumped from the mash tun to your recipe volume. Then top off water can be added and the brew day begins!

So there we are! Don't b afraid to try new things man! We are only 10,000 years into beer. There are thousands of years left to go! Things are bound to change!!

Enter your email address to join: