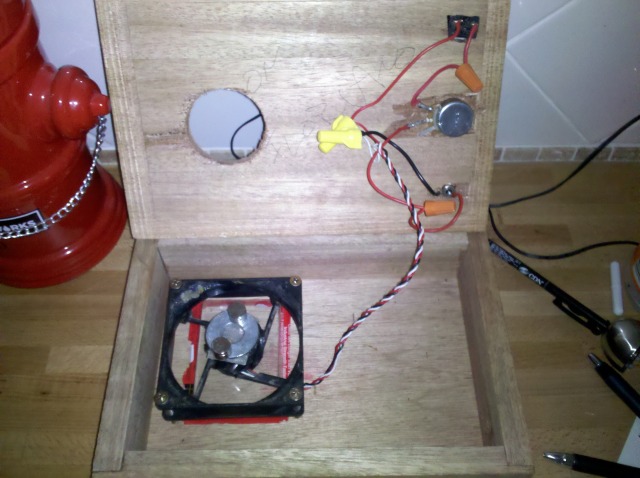

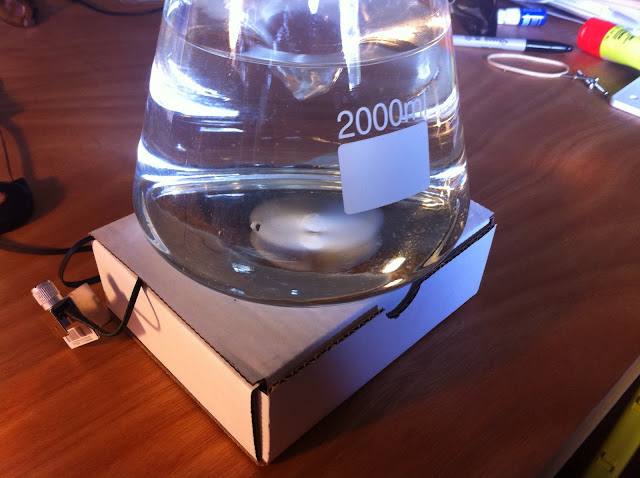

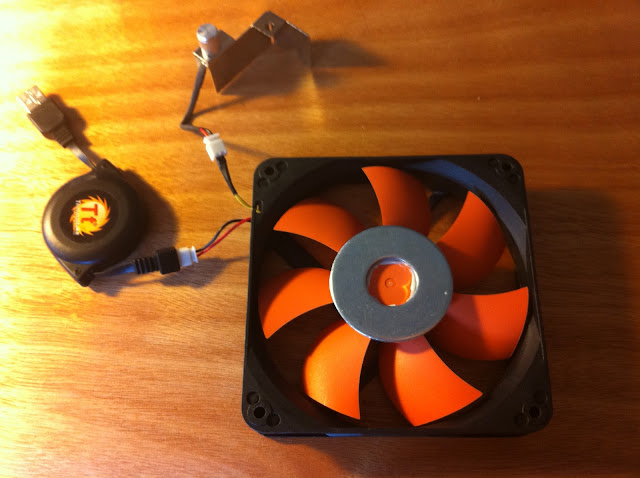

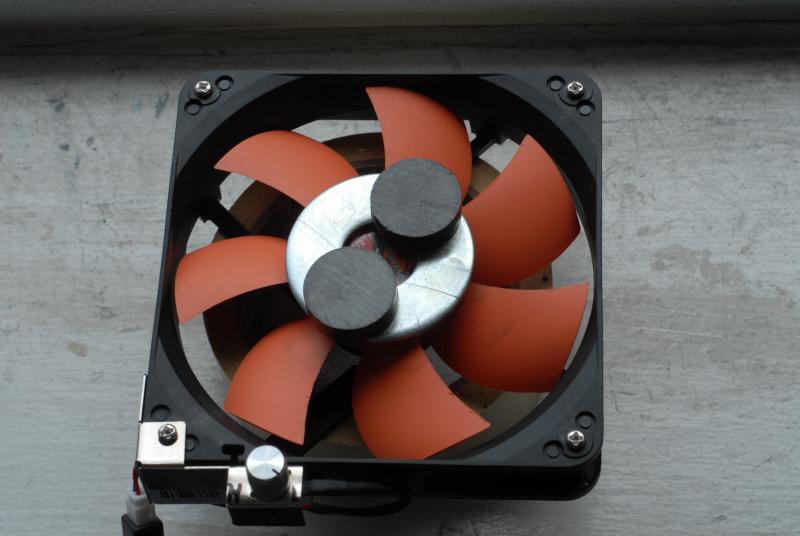

I know there are tons of stir plate build threads on here, but just wanted to share this fan I found on Amazon and see if anyone has tried using it. It is USB, so you could just use any of the myriad of USB equipped phone chargers to power it. It already has a speed control, so no wiring needed at all! Just would need to make a case that would leave the speed control knob accessible.

It's only $11.50 on Amazon

http://www.amazon.com/dp/B00080G0BK/?tag=skimlinks_replacement-20

It's only $11.50 on Amazon

http://www.amazon.com/dp/B00080G0BK/?tag=skimlinks_replacement-20

Last edited by a moderator: