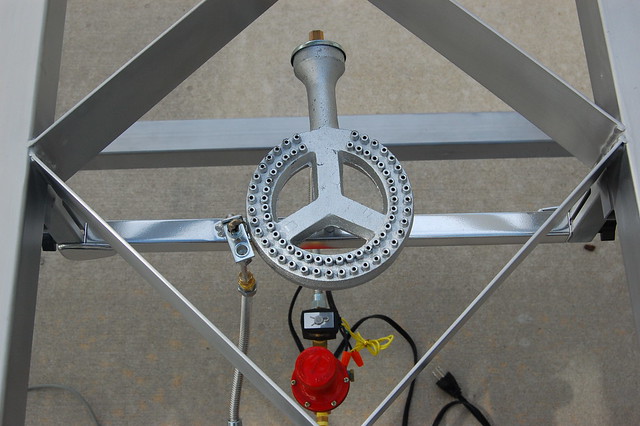

So after my first brew on my single tier Brutus style rims stand I realized due to it always being breezy here I really need some additional shielding. So looking for some options specifically on material / mounting

1) 2 pilot burners I need to protect. These are the q314a manual pilots. They blow out super easy! I was thinking about using aluminum sheet for this. Opinions?

2) I am thinking on the two ends I need to put a plate the width of the stand and probably around 12" high so it will stop wind through the sides. Here is where I need the most help - a good material and how to attach it. Thin stainless could work I guess but will likely be pricey.

And I won't be welding on it - it's already been coated in ceramic (the stand).

Thanks!

1) 2 pilot burners I need to protect. These are the q314a manual pilots. They blow out super easy! I was thinking about using aluminum sheet for this. Opinions?

2) I am thinking on the two ends I need to put a plate the width of the stand and probably around 12" high so it will stop wind through the sides. Here is where I need the most help - a good material and how to attach it. Thin stainless could work I guess but will likely be pricey.

And I won't be welding on it - it's already been coated in ceramic (the stand).

Thanks!