It is doing very well actually. It only has one carboy currently. Since Jackson is in the middle of a cold snap, it's insulating rather than cooling.

If I lived up north, I would have gotten a two stage controller and possible heating element, which would have worked great with the fans.

The cabinet itself is warm, but both the probe and the fermometer show the carboy at a nice 64F degrees.

The real test will come in the spring with a fuller load.

Total Cost was $236, though a half of that is the ranco and foam board. I'm working of what I remember on the project, so I may be a bit off without receipts in front of me.

Materials

(2x)4x8 2" Foam board R7.8 $60ish

(6-7?) 12'x2"x4" boards $18ish?

(2x) Caulk $12

(1x) Liquid Nails $5

(1.3x) Box of 4" screws $10

(1x) Box of 2" drywall screws $5ish

(1x) 1/4" C/D plywood $14

(5x) 1/4"x2.5" bolts, nuts, Washers (I used stainless, though I had them laying around) no more than $4-5

(2x) 3" hinges $8

(1x) Package of 4 1.5" corner braces

(1x) Ranco Controller $57 Ebay ($90 if you need a two-stage)

(1x) Refrigerant Unit Umm....I guess $17

Things I used that probably aren't needed are:

Wheel-Casters @ $3.99 a piece

Three fans 12v fans @ 4.99 a piece(newegg would have been cheaper)

Transformer for said fans @ $4.59 (radio shack)

I had all the wiring and other electrical around.

It took about 2 weekends to finish, though I could have done it MUCH faster with a bigger work space and/or a table saw.

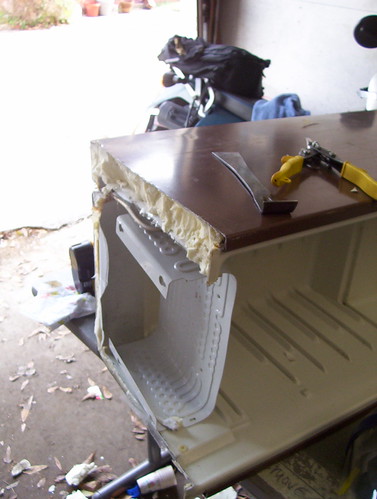

As for getting the heart of the project, the refrigerant unit, I just lucked out on Craigslist. Getting it apart was quite easy, though EXTREME CAUTION was needed when removing the top to get the unit out and making sure the refrigerant line didn't get kinked when moving.

I can write up a how-to from memory and taking some measurements, though it is pretty self-explanatory.