Sorry, I'm still confused. On a 20amp circuit your going to constantly be tripping the breaker if your using a 4500 watt element and pump at the same time.

a march pump pulls 1-2 amps at 120v. (if it could run on 240), it would theoretically only pull 0.25 to 0.5 amps. normally, people just plug in their pump to a regular 120v outlet instead of messing around with splitting 240. it can be done either way, but if you are close to the max for your circuit, you should just run the other low power items from the closest wall outlet.

the 80% rule is a good rule for planning when we are talking about non-dedicated circuits, like general use wall outlets. if you have a 20A circuit and positively know that you are only going to pull 19 amps at any given time, then its perfectly fine to do that. if you hover right around 20A, you will probably end up tripping the breaker every so often.

also, since we are talking about resistive loads, "240" volts is often less when you take into account resistance of the legnth of wiring from the incoming feed (but "240v" can sometimes be higher and your element would pull more current, so its important to actually measure the voltage).

4500w @240v = 18.75A

a 4500w element on only 230v = just under 18A (and 4100w of heating power)

a 4500w element on only 220v = just over 17A (and 3800W of heating power)

If you wires in the wall are 10 AWG which is rated for 30amps, wouldn't you just need to replace the breakers to get a 5500 watt element?

as long as the outlets and

everything behind the breaker are rated to handle 30 amps, then yes.

According to the "Electric Heat.xls" spreadsheet, it takes 9 more minutes on a 4500w than a 5500w to get 15 gal. from 70 deg to 170 deg. I'm OK with that.

it requires 12,450 BTUs to move 15 gallons of water 100 degrees.

each 1000w of power puts out ~3400BTUs in an hour.

so 4500w = 15,300 BTU/hr = 48 minutes to heat

and 5500w = 18,700 BTU/hr = 39 minutes to heat

your spreadsheet appears to be correct.

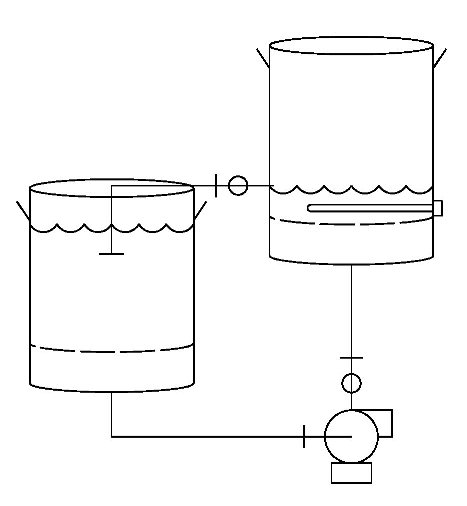

im not sure, though, that i like the idea of running the element in the boil kettle while circulating. i can think of many instances where it could become exposed to air, and you really want the wort to be quickly circulating around it like it does in a common RIMS tube.

and if you thought dialing in PID settings was tough before, now you have the variable flow patterns in the boil kettle to make your life harder.

additionally, you will have a large volume of wort that isnt going to be in contact with the grain. this could give you trouble trying to keep a good water:grain ratio, and it would reduce enzyme activity in the mash.

Hurray for the whip being back! Sorry about the pack my wife was greatly dissappointed. I just drank another homebrew and it was ok.

Hurray for the whip being back! Sorry about the pack my wife was greatly dissappointed. I just drank another homebrew and it was ok.