bmurph

Well-Known Member

I have some questions about wiring a RIMS, sorry couldn't find the specific info I'm looking for on the forum. Most wiring schematics I look at show everything as belonging to one big series of circuits and converging into a single 3-prong plug. I'm wondering if the pump needs to be included in all of that. Could I keep it separate from the rest of the wiring and just turn it on and off manually?

Also, which components will need to be grounded? I assume the SS hardware, but what about switches, electrical components?

And I'm using a 25A SSR- will I need a heat sink?

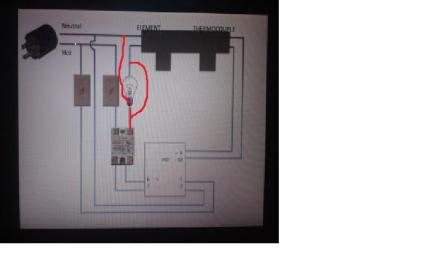

One last thing--wiring this whole thing up doesn't look too bad, but I'm unsure of the connectivity; there is good bit of variation in the schematics I've viewed. Would anyone mind sending me pics of their own schematics?

Also, which components will need to be grounded? I assume the SS hardware, but what about switches, electrical components?

And I'm using a 25A SSR- will I need a heat sink?

One last thing--wiring this whole thing up doesn't look too bad, but I'm unsure of the connectivity; there is good bit of variation in the schematics I've viewed. Would anyone mind sending me pics of their own schematics?