The thing that made the light bulb go on for me was learning why different styles of beer became associated with different places in the world.

In places (the UK) where water was very alkaline, Stouts and Porters were the thing. Why? Because to bring the pH of the mash down to the most effective range (5.2 to 5.6, generally), something acidic needed to be added. Dark grains are more acidic than light grains, thus the dark grains brought the pH down to range.

In places (Pilsen) where the water is not very alkaline, using such dark grains would have brought the pH down too far--so lighter grains were used because they wouldn't bring down the pH as effectively. Think light lagers for an example of this, a Pils.

That's why many brewers (like

@Jag75 above) start with RO water and build it up. When doing that, you can make any composition of water you want, and you'll not be dependent on what your water allows you to do effectively.

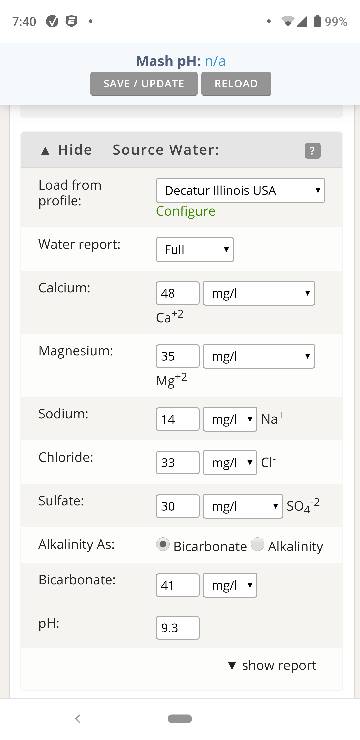

My municipal water is drawn from limestone formations 1100 feet down. It's very alkaline. In all-grain, suitable only for stouts, really. Thus my RO water. My typical strike water is 1 gallon tap water, 7.25 gallons RO water, and the necessary salts and such to bring it up to where I want it. CaCL2, MgSO4, SMB, maybe some lactic acid, maybe some CaSO4. Some BrewtanB.

The above chem formulas are Calcium Chloride, Magnesium Sulfate (Epsom Salt), sodium metabisulfate, and Calcium Sulfate (Gypsum). Took me a long time to make those part of my vocabulary which, to anyone struggling with water chemistry, I'd advise doing. Maybe what makes this harder is people bounce back and forth between the formulas, the names, and the common names: CaSO4, Calcium Sulfate, Gypsum. It was when I realized that all three of those terms were being used interchangeably that I had an easier time of it.