ajmartinez

Well-Known Member

Copy/pasted from my blog.

Twelve days ago, I started brewing my own beer. Today, I made a stop at DeFalco's Home Wine & Beer Supplies to pick up a few things I needed to finalize this brewing project. Lacking a hydrometer was making it pretty impossible to know if fermentation had halted or not, so that was number one on my list. I also picked up a floating thermometer, a bottle of Iodophor for sanitizing my equipment, a bottle brush, a case of 12oz. bottles, a few hundred bottle caps, a bottle capper, and a packet of priming sugar (fructose).

Assorted supplies:

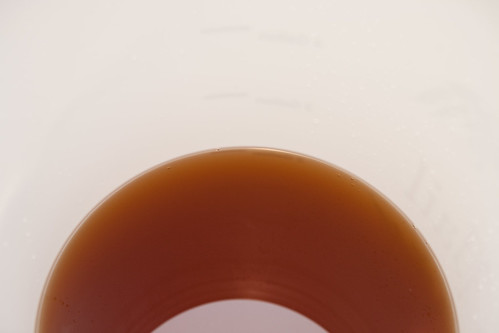

When I got home from DeFalco's, I prepared to take the first sample of my West Coast Pale Ale from my Mr. Beer brew keg. Surprisingly enough, what poured out looked, smelled, and even tasted a lot like beer. It may have been a bit on the sweet side, but I am not complaining right now. Once carbonated, it will definitely pass as drinkable in my book.

First sample:

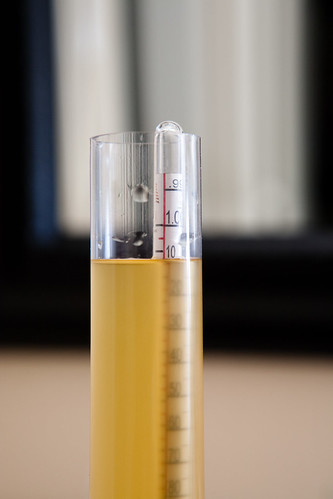

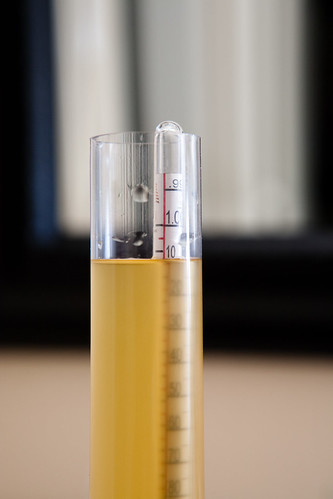

The hydrometer reads right around 1.010 for the specific gravity right now, at 72°F. According to the handy dandy sheet that came with the hydrometer to correct for temperature I add .002. So we'll call my reading today 1.012. Since I did not have this instrument when I actually made the wort, I have no earthly idea what the original gravity was. That being the case, I will hold off another few days and take a reading again. If nothing has changed, I am going to start bottling. I've not quite decided exactly how I plan on doing the priming part but I'm sure I'll get at least 30 different suggestions before that time comes!

Hydrometer reading:

I think an Apfelwein is likely to be the next thing my Mr. Beer ferments, while I start gathering the equipment required to step up to 5 gallon all-grain batches of beer. This is definitely a lot of fun, and if the result is drinkable beer, I am all for it.

Twelve days ago, I started brewing my own beer. Today, I made a stop at DeFalco's Home Wine & Beer Supplies to pick up a few things I needed to finalize this brewing project. Lacking a hydrometer was making it pretty impossible to know if fermentation had halted or not, so that was number one on my list. I also picked up a floating thermometer, a bottle of Iodophor for sanitizing my equipment, a bottle brush, a case of 12oz. bottles, a few hundred bottle caps, a bottle capper, and a packet of priming sugar (fructose).

Assorted supplies:

When I got home from DeFalco's, I prepared to take the first sample of my West Coast Pale Ale from my Mr. Beer brew keg. Surprisingly enough, what poured out looked, smelled, and even tasted a lot like beer. It may have been a bit on the sweet side, but I am not complaining right now. Once carbonated, it will definitely pass as drinkable in my book.

First sample:

The hydrometer reads right around 1.010 for the specific gravity right now, at 72°F. According to the handy dandy sheet that came with the hydrometer to correct for temperature I add .002. So we'll call my reading today 1.012. Since I did not have this instrument when I actually made the wort, I have no earthly idea what the original gravity was. That being the case, I will hold off another few days and take a reading again. If nothing has changed, I am going to start bottling. I've not quite decided exactly how I plan on doing the priming part but I'm sure I'll get at least 30 different suggestions before that time comes!

Hydrometer reading:

I think an Apfelwein is likely to be the next thing my Mr. Beer ferments, while I start gathering the equipment required to step up to 5 gallon all-grain batches of beer. This is definitely a lot of fun, and if the result is drinkable beer, I am all for it.