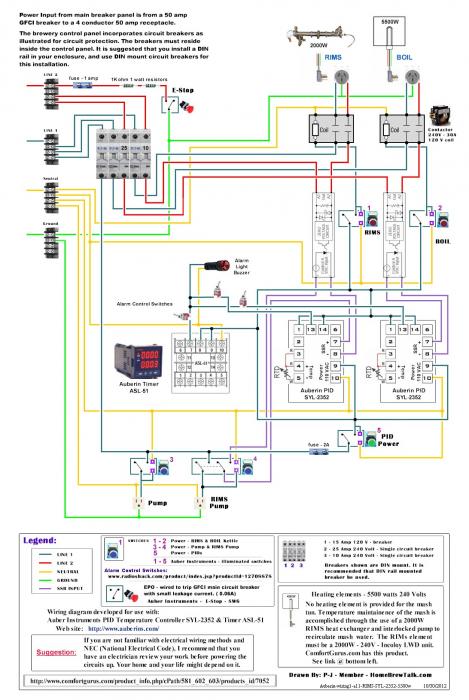

I've been seriously planning a HERMS setup (240v, 50a, 2 element, 2 pump) for the past three months or so, and have in the last month entered into a partnership with two local brewers/friends to collaborate on a 15 gallon setup.

In reading a lot of the threads here, I've come across several mentions of people wishing they had started off with a DIN rail setup and that they hope to transition to the same in a further iteration of their build. I come from an engineering background (Mining/Process,) and am fairly comfortable with the overall architecture, design and implementation of a traditional backplane install, but am completely unfamiliar with DIN rails.

Does anyone have a good source for a primer for understanding/transitioning to DIN rails? From what I've read, it would be a great option for us in terms of experimentation/adaption, but am having trouble finding source material to bring me up to speed on the cons and benefits of sourcing components for a DIN setup. Anyone have suggestions?

Thanks!

In reading a lot of the threads here, I've come across several mentions of people wishing they had started off with a DIN rail setup and that they hope to transition to the same in a further iteration of their build. I come from an engineering background (Mining/Process,) and am fairly comfortable with the overall architecture, design and implementation of a traditional backplane install, but am completely unfamiliar with DIN rails.

Does anyone have a good source for a primer for understanding/transitioning to DIN rails? From what I've read, it would be a great option for us in terms of experimentation/adaption, but am having trouble finding source material to bring me up to speed on the cons and benefits of sourcing components for a DIN setup. Anyone have suggestions?

Thanks!

If you really want to go all out on your control board you can use wire way or wire duct to conceal the wiring.

If you really want to go all out on your control board you can use wire way or wire duct to conceal the wiring.