archiefl98

Well-Known Member

So I picked up two 1/2 barrel Sankes and one 1/4 barrel old style keg today. I'm turning the Sankes into a brew kettle and a HLT (Thanks Bobby_M). I have no idea what to do with the 1/4 barrel. First, since it's got some old style connector on it, I don't even know how to relieve pressure, much less how to disassemble it.

Here's a shot of the keg:

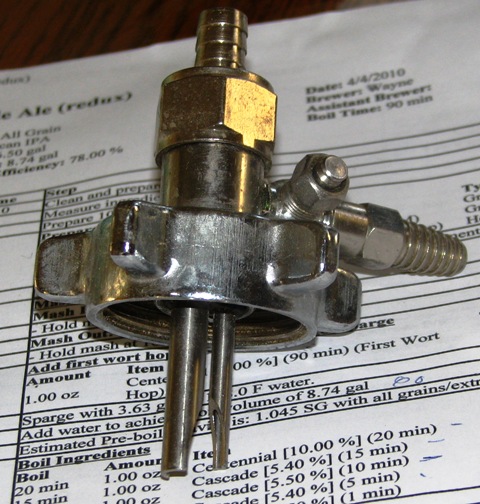

Here's a closeup of the top:

And then, there's a place for a bung on the side of it I guess. WTF is this and what do I do with it?

It's about half full from what I can tell, so at least I know it holds pressure. What would you do with this thing if you owned it? How do I disassemble it?

Any help is greatly appreciated on this one.

Thanks,

Arch

Here's a shot of the keg:

Here's a closeup of the top:

And then, there's a place for a bung on the side of it I guess. WTF is this and what do I do with it?

It's about half full from what I can tell, so at least I know it holds pressure. What would you do with this thing if you owned it? How do I disassemble it?

Any help is greatly appreciated on this one.

Thanks,

Arch