I am thinking about doing something like this, except, being greedy, I want 3 compartments at different temps (ale ferm compart, lager ferm compart, and corny cold storage compart) . I have little electical wiring knowlege and do not want to mess with it. So, what I was thinking about is marrying together BK's side by side fridge fermentor trick-out with a few ideas from his really cool keezer/glass cabinet plans to create something like this:

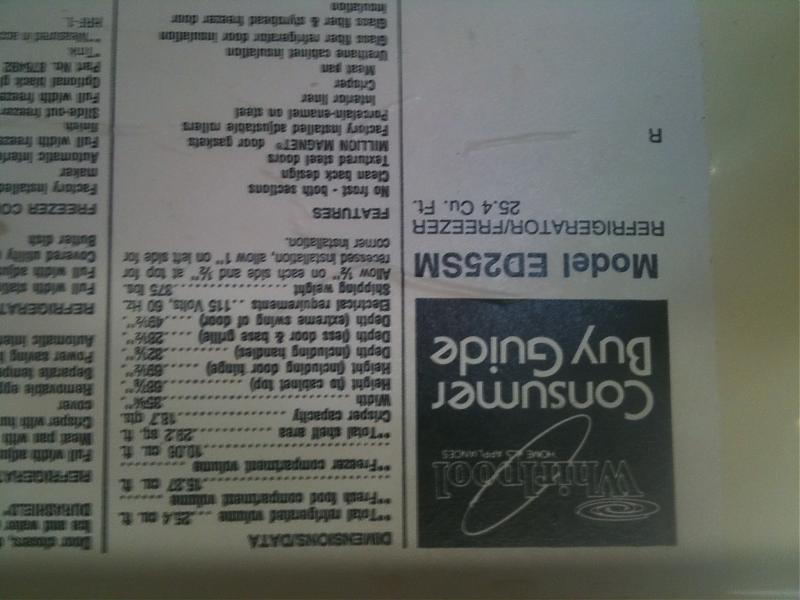

(1) get a cheap/free large CraigList side by side fridge.

(2) Instead of completely ripping out the center wall, only rip half out from the ground up to a height that will fit corny kegs and a middle shelf.

(3) create a shelf across the middle on a wooden bracket that sits flush with the center wall. Now you have 3 compartments (1 large compartment on the bottom where the cold air comes in for storing lagering cornys and 2 side by side compartments on top).

(4) insulate the bottom of the middle shelf and rip out the door moldings and replace with something flush/smooth that will rest against a gasket on the side edge of the middle floor to create an air-tight barrier between the lower compartment and 2 upper compartments when the fridge doors are closed.

(5) in each of the 2 upper compartments on opposite sides drill 2 holes to insert 2 large tubes with 120mm computer fans glued on top of each tube. attach the so that in each compartment 1 tube goes to near the bottom of the lower cold compatment and blows air into the floor of the compartment above. the other tube goes from the middle floor to near the top of each compartment to blow warm air down to the lower compartment. As others who originally thought up of this type of system have noted, the idea is to blow cold air in near the bottom of each upper compartment and recirculate warmer rising air back into the lower compartment, with the fans controlled by thermostats.

(6) get 2 cheap house A/C-heater battery run digital thermostats. Wire the fans to the thermostats fan control connectors (power source for fans are spliced wall warts from cell phones, etc). I seen from someone else using this method that you can easily solder out the on-board thermisters on these cheap house thermistats, solder on long wires to the board in their place and then re-solder the thermisters onto the wire to allow you to attach the thermister to your fermentation vessel. Set temp on upper left chamber (which is above the cooling unit on what was the freezer side and will be colder) to your desired lager ferm temp; set the temp on the upper right chamber to your warmer ale ferm temp.

(7) plug the fridge into one of those temp controllers that in turns plugs into an electrical socket. place the temp probe in the lower compartment and set for someting like 29-30 degrees to lager your cornys and provide to cold air source for upper compartments on demand. This controls the cold compartment with no electrical wiring needed.

I am thinking that at this point it would be finished with very minimal DIY skills and little electrical wiring skills. If the frige is large enough, you could ferment up to 4 beers at a time ( 2 in each compartment) and store a a bunch of cornys. Has anybody thought about or tried doing it this way? Any logic/design flaws here that come to mind before I try something lilke this?