Hey,

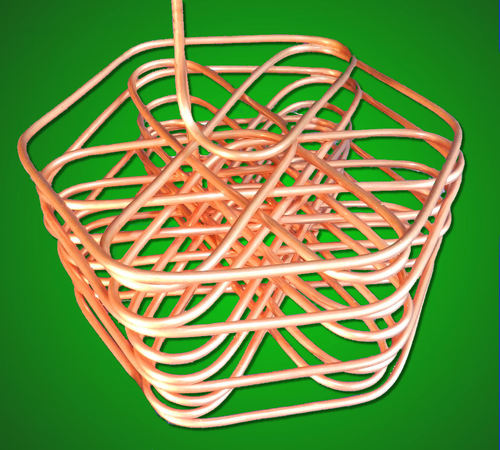

I have been brewing for about a year and I have been looking at chillers (getting tired of ice baths). I saw this http://www.ebay.com/itm/NEW-WORT-CHILLER-DESIGN-PEAK-EFFICIENCY-/110841991716?pt=LH_DefaultDomain_0&hash=item19ceb29224 and wanted to know if anyone here has used one of these?

Thanks

I have been brewing for about a year and I have been looking at chillers (getting tired of ice baths). I saw this http://www.ebay.com/itm/NEW-WORT-CHILLER-DESIGN-PEAK-EFFICIENCY-/110841991716?pt=LH_DefaultDomain_0&hash=item19ceb29224 and wanted to know if anyone here has used one of these?

Thanks

. So my buddy and I figured we would check the water usage while we were compairing them. The 1/4" used a gallon of water every minute and sixteen seconds. The 1/2" used a gallon every 16 seconds. I am totally happy with the chiller as the main reason I bought it was to keep my water usage down and since the chilling time was the same, it's kind of a double bonus!

. So my buddy and I figured we would check the water usage while we were compairing them. The 1/4" used a gallon of water every minute and sixteen seconds. The 1/2" used a gallon every 16 seconds. I am totally happy with the chiller as the main reason I bought it was to keep my water usage down and since the chilling time was the same, it's kind of a double bonus!