I picked up a 10-gallon cylindrical rubbermaid cooler for Home Depot and put a weldless ball valve on it with a torpedo screen; the problem being, the torpedo screen didn't fit completely and I had to bend it a bit to make it lay mostly flat on the cooler bottom. Will this kink have an effect on performance? Pictures:

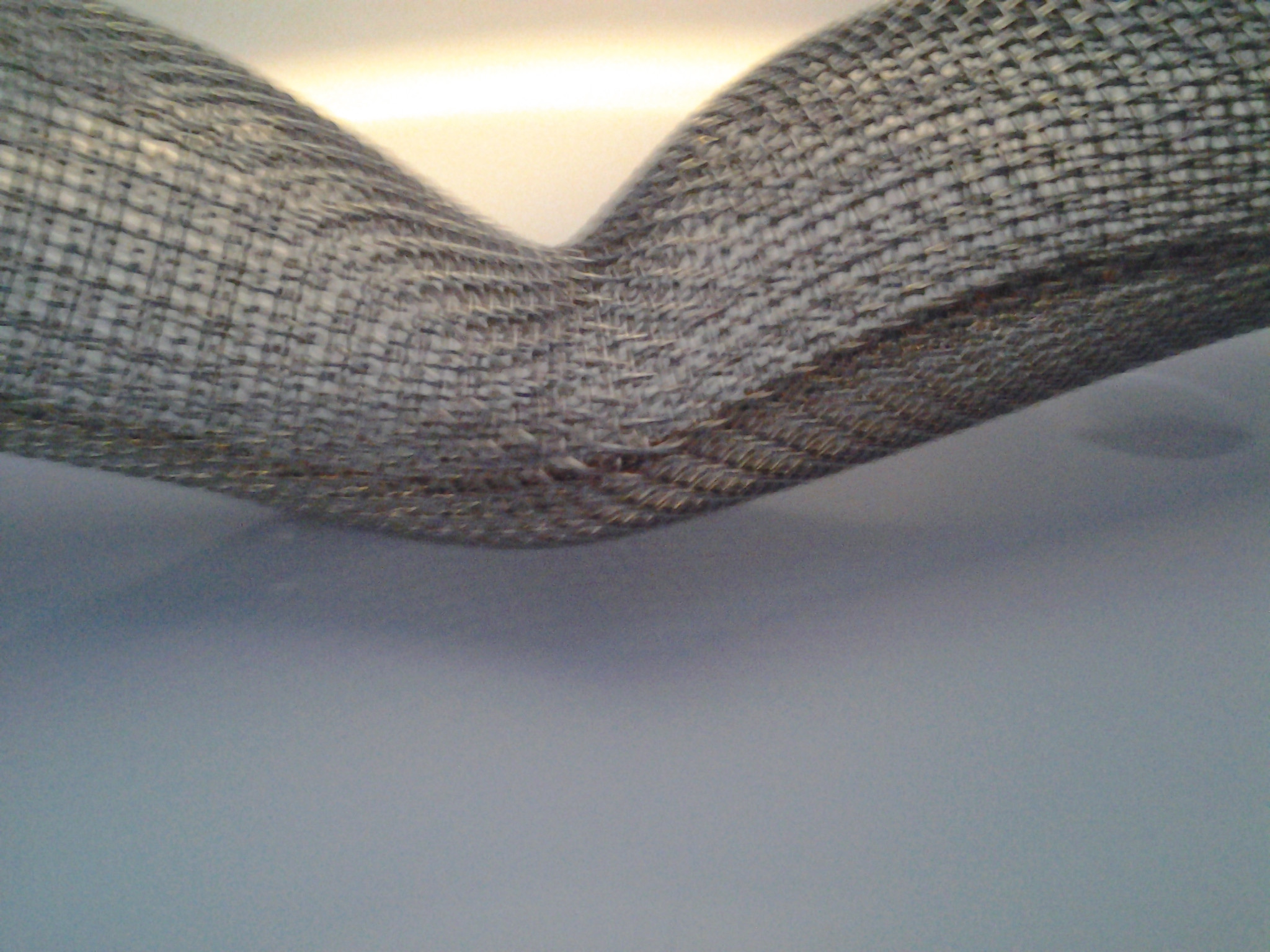

Top-down view:

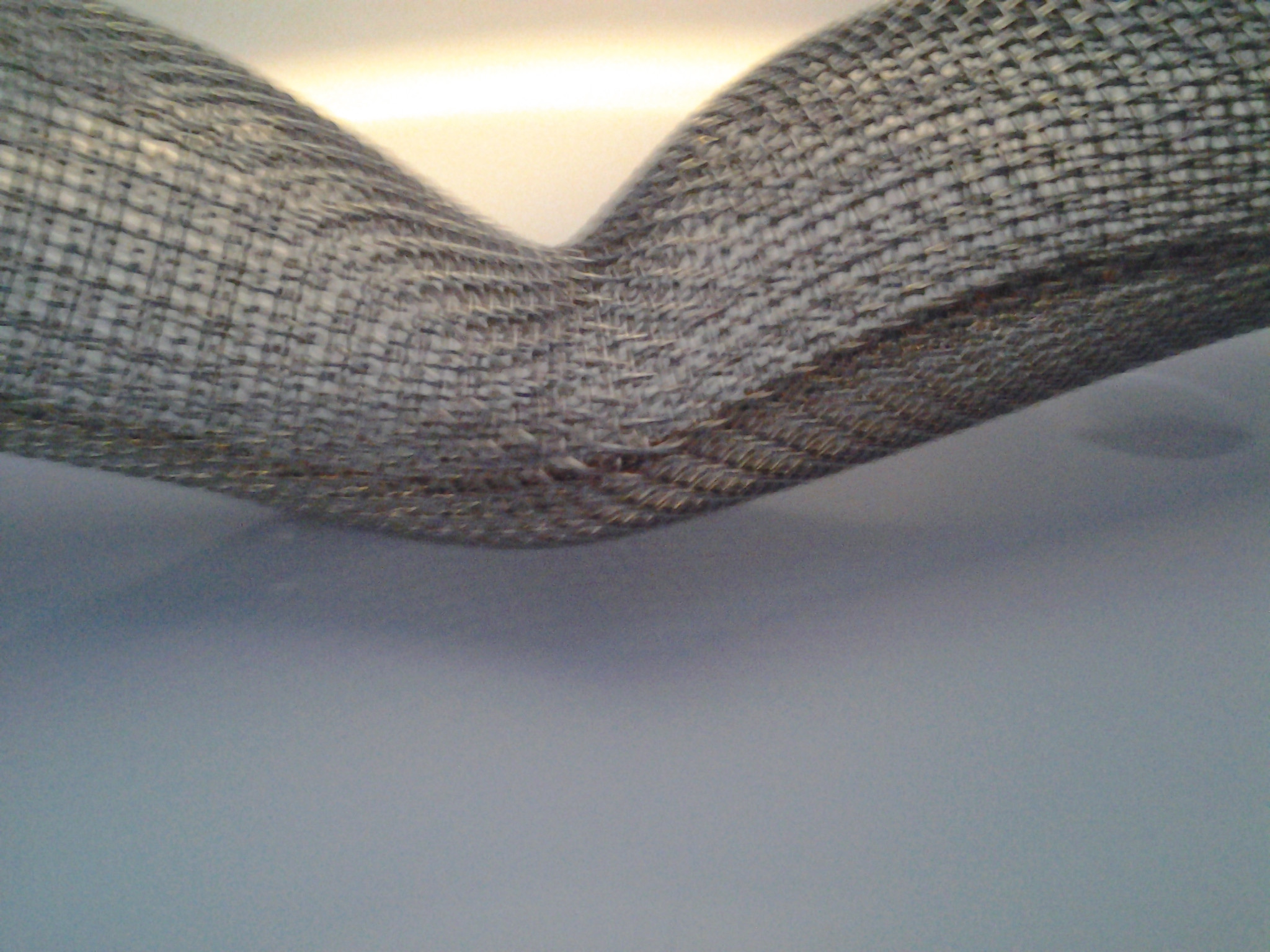

Side view 1:

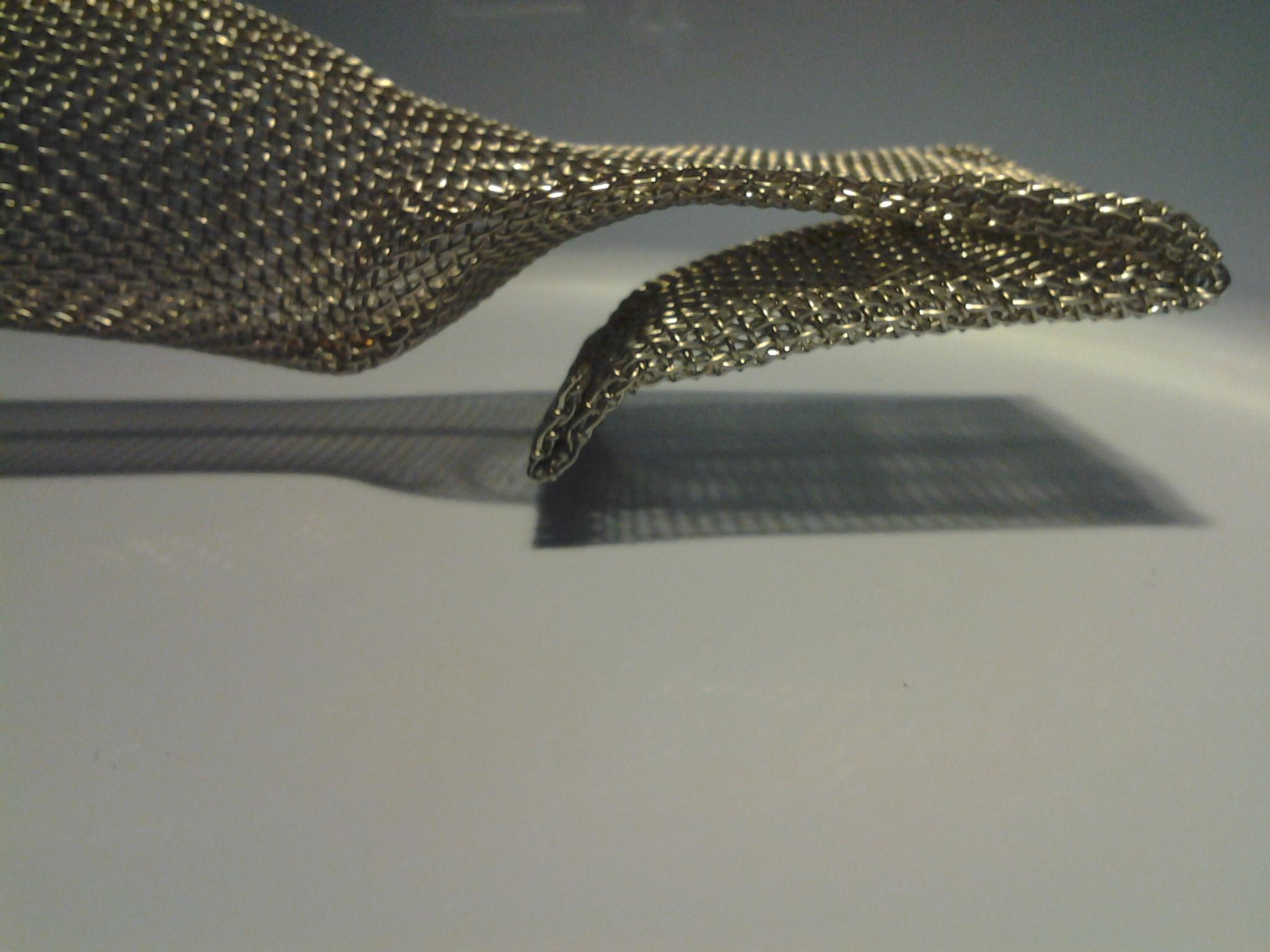

Side view 2:

Top-down view:

Side view 1:

Side view 2: