RedDragon

Well-Known Member

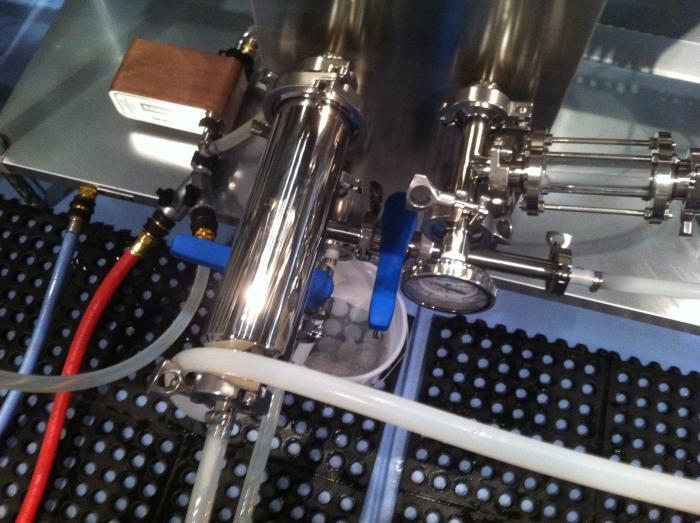

Well, I have worked the past two years putting together the business plan and working on a production brewery. My wife and I decided to put it off for a few years until the kids are older. So, I go the go ahead to move forward with revamping the home brewery. I recently sold my all grain set up and now am moving forward with a 20 gallon, electric system. I am "renovating the garage" into an ultimate brewery. If you are interested, I will be posting info on my facebook page (makes it easier to update in one place).

Cheers!

Tom

https://www.facebook.com/#!/pages/Red-Dragon-Brewery/407139329322343

Cheers!

Tom

https://www.facebook.com/#!/pages/Red-Dragon-Brewery/407139329322343

![544269_490513960984879_900560288_n[1].jpg 544269_490513960984879_900560288_n[1].jpg](https://cdn.homebrewtalk.com/data/attach/96/96086-544269-490513960984879-900560288-n-1-.jpg)