Everyone here keeps us VERY busy.

I'm managing to get some of my personal brew related projects worked out.

Thanks for keeping us busy!

Also want to say thank you to several people I borrowed all these great ideas from off the forum!

I would list them here.......

I'm in the process of changing over to 1/6 barrel kegs for serving and fermenting.

I have a couple 1/2 barrel kegs to do larger 10-12 gallon batches when needed.

These are brand 1/6 (5.17 gallon) new slims I bought locally. Not cheap but I wanted them to all match and have the same spear hardware etc. 10 keg minimum forced my hand!

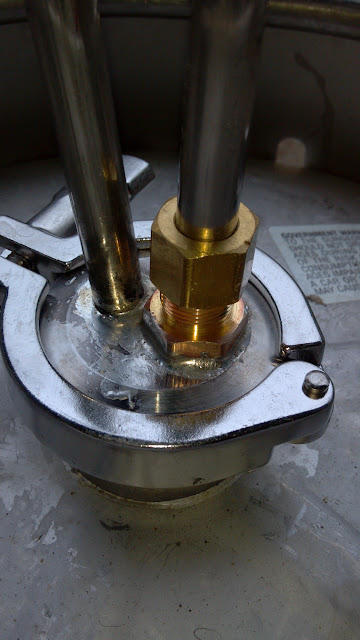

Had to figure out a way to clean them so I modified a tap by removing the ball and check valves. Soldered 1/2 x 3/8 NPT reducing hex nipples to the nuts so I could connect camlocks to the in and out.

So using a sump pump and some hose connections I can recirculate cleaner and then run rinse water through the sanke tap. Water flows into the liquid connection sprays up the spear and drain out the co2 side.

I have a wand with sprayer head that hooks onto the camlock I put on the pump so I can switch between this and the sanke connector. This allows me to clean the fermenters without installing the spear.

I got impatient and made my own tool to press on the spears to make it easier to get the spiral rings in and out. Not pretty but it works great.

1/4" plate steel and a harbor freight C clamp cut and welded. I use a nut and socket to push on the spear.

Fermenting setup will be documented when I get the parts. Plan to use 2" tri-clover and to modify some 2" caps by drilling and adding some 1/2" pickup tubes through them.

I'm managing to get some of my personal brew related projects worked out.

Thanks for keeping us busy!

Also want to say thank you to several people I borrowed all these great ideas from off the forum!

I would list them here.......

I'm in the process of changing over to 1/6 barrel kegs for serving and fermenting.

I have a couple 1/2 barrel kegs to do larger 10-12 gallon batches when needed.

These are brand 1/6 (5.17 gallon) new slims I bought locally. Not cheap but I wanted them to all match and have the same spear hardware etc. 10 keg minimum forced my hand!

Had to figure out a way to clean them so I modified a tap by removing the ball and check valves. Soldered 1/2 x 3/8 NPT reducing hex nipples to the nuts so I could connect camlocks to the in and out.

So using a sump pump and some hose connections I can recirculate cleaner and then run rinse water through the sanke tap. Water flows into the liquid connection sprays up the spear and drain out the co2 side.

I have a wand with sprayer head that hooks onto the camlock I put on the pump so I can switch between this and the sanke connector. This allows me to clean the fermenters without installing the spear.

I got impatient and made my own tool to press on the spears to make it easier to get the spiral rings in and out. Not pretty but it works great.

1/4" plate steel and a harbor freight C clamp cut and welded. I use a nut and socket to push on the spear.

Fermenting setup will be documented when I get the parts. Plan to use 2" tri-clover and to modify some 2" caps by drilling and adding some 1/2" pickup tubes through them.