- Joined

- Nov 18, 2008

- Messages

- 2,058

- Reaction score

- 25

I have been fermenting my 10 gallon batches in a sanke keg using a BrewersHardware.com Sanke-Fermenter-Kit:

http://www.brewershardware.com/Sanke-Fermenter-Kits/

While this works great... the problem is cleaning the keg:

I have built a keg washer (to use for corny's, carboys, and sankes) that sprays warm oxyclean, I have soaked, I have brushed, but I'm still not 100% sure it's clean. When I look in the opening using a flashlight, there appears to be "stuff" about where the 10 gallon mark would be.

What I'm thinking about:

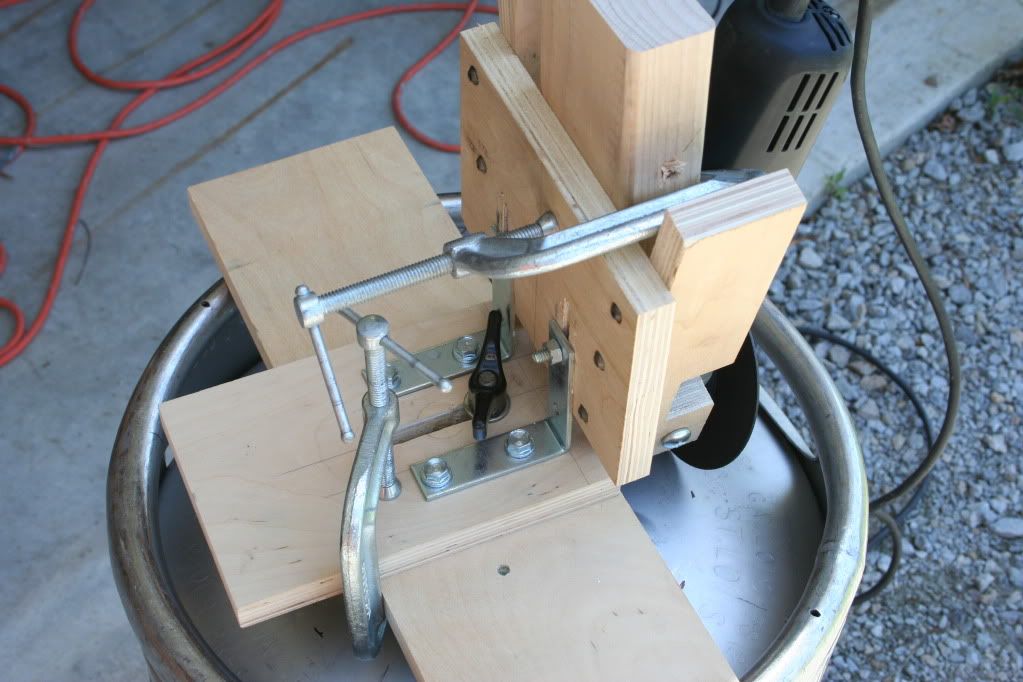

I still have the 12" cut outs from my keggle conversions. I'm thinking about cutting a smaller opening (8"-10"), in the fermenter keg and then finding a gasket of some type and clamping the larger cutout over the hole. This would give me better access to see whats going on and possibly clean by hand.

Cutting the hole would be no problem. Finding a suitable gasket material (I like to transfer with co2 pressure) and a clamping method are my concerns. I don't have GreenMonti's mad welding skills, nor do I live next door to him so the clamping method needs to be more mechanical.

I'm thinking of a couple braces that would slide under the ring on the top of the keg and then maybe thumb screws that would push down on the new "lid" to secure it.

So what do you think?

Things I'm missing, recommendations advice??

Thanks,

Ed

http://www.brewershardware.com/Sanke-Fermenter-Kits/

While this works great... the problem is cleaning the keg:

I have built a keg washer (to use for corny's, carboys, and sankes) that sprays warm oxyclean, I have soaked, I have brushed, but I'm still not 100% sure it's clean. When I look in the opening using a flashlight, there appears to be "stuff" about where the 10 gallon mark would be.

What I'm thinking about:

I still have the 12" cut outs from my keggle conversions. I'm thinking about cutting a smaller opening (8"-10"), in the fermenter keg and then finding a gasket of some type and clamping the larger cutout over the hole. This would give me better access to see whats going on and possibly clean by hand.

Cutting the hole would be no problem. Finding a suitable gasket material (I like to transfer with co2 pressure) and a clamping method are my concerns. I don't have GreenMonti's mad welding skills, nor do I live next door to him so the clamping method needs to be more mechanical.

I'm thinking of a couple braces that would slide under the ring on the top of the keg and then maybe thumb screws that would push down on the new "lid" to secure it.

So what do you think?

Things I'm missing, recommendations advice??

Thanks,

Ed