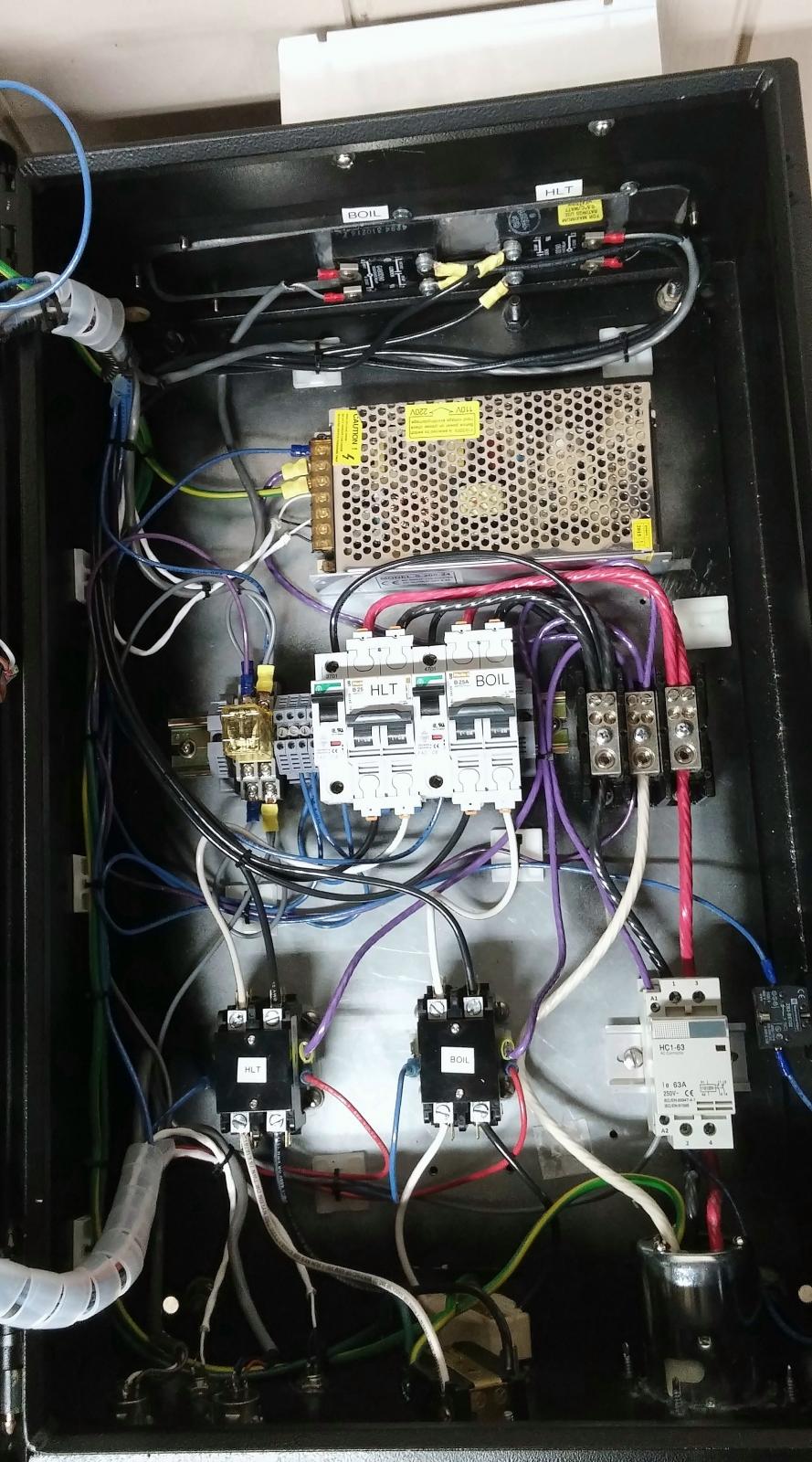

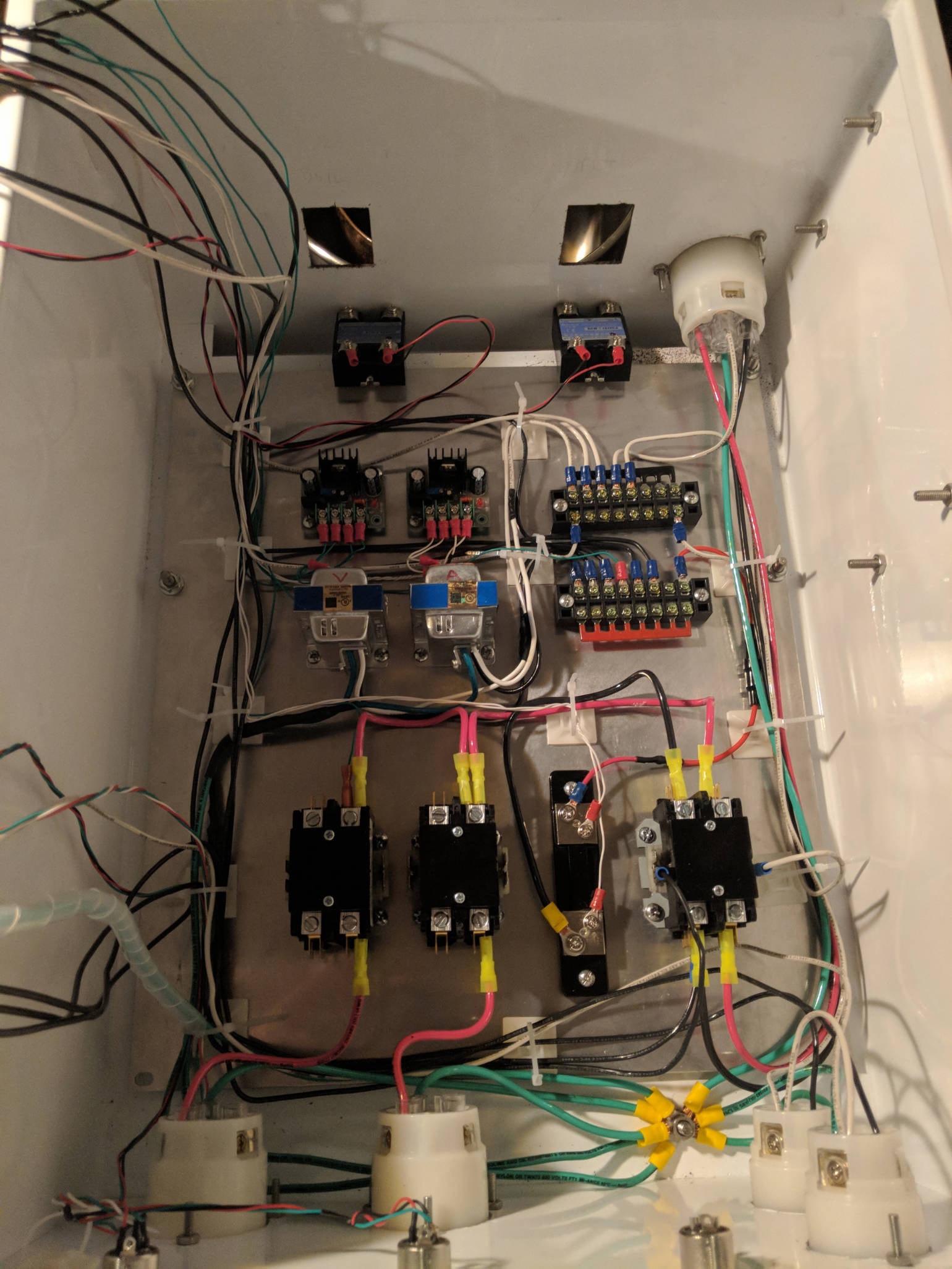

Here is my newly wired panel. It took a very long time to get here with kids, moving, new house, new job. It is a 50amp Kal kit with a minor change.

Started out with a combine. This model was used for many years on the family farm. Every summer I would help my Dad get it ready for harvest. Lots of good memories associated with the IH 1482.

View attachment ImageUploadedByHome Brew1477159442.771127.jpg

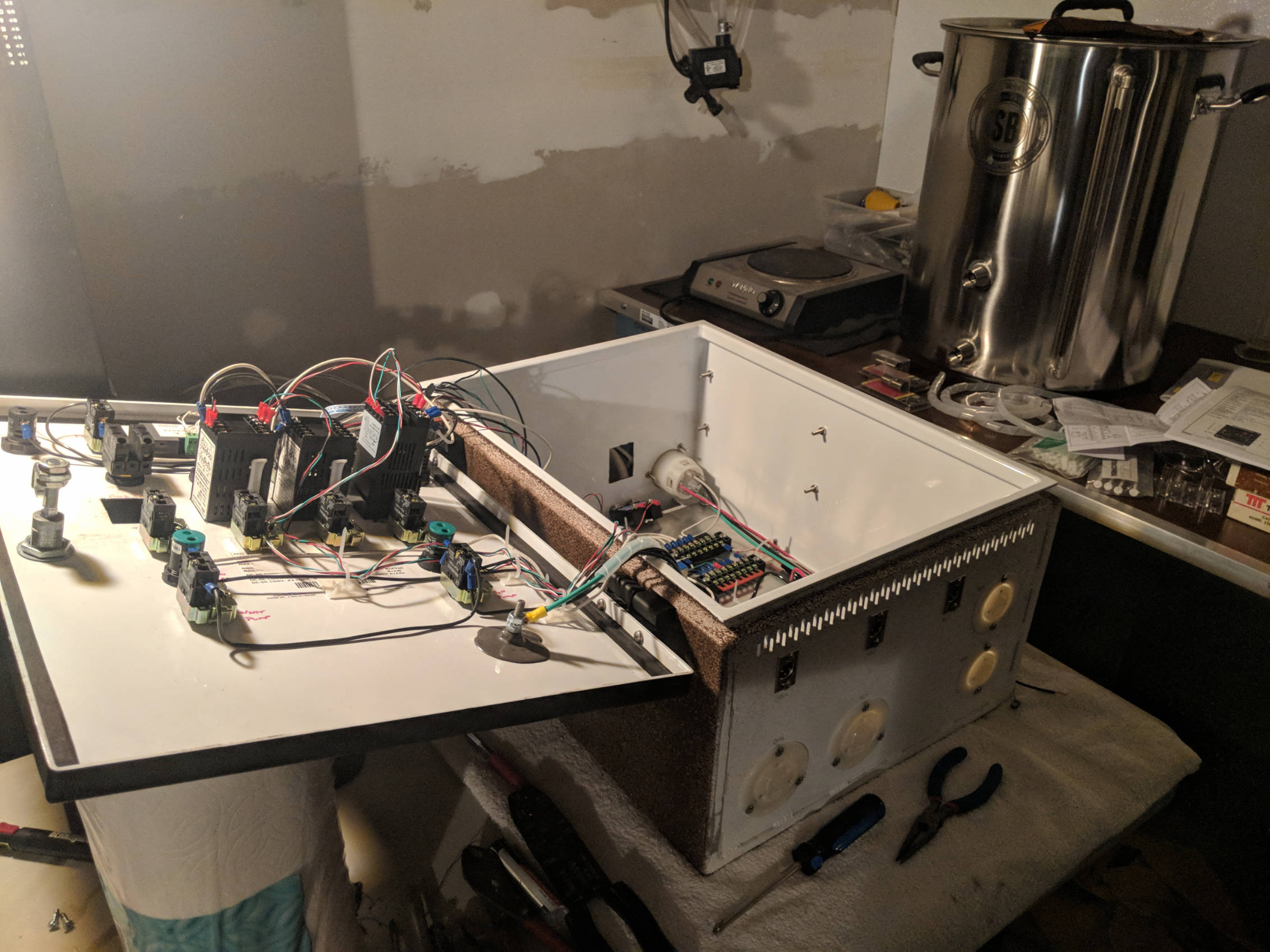

Then I got a metal worker friend to turn it into a box. And started cutting holes.

View attachment ImageUploadedByHome Brew1477159487.077557.jpgView attachment ImageUploadedByHome Brew1477159499.425736.jpgView attachment ImageUploadedByHome Brew1477159511.063729.jpg

I ended up with kind of a reverse of most panels, with the door on the back. This does make it a bit of a pain to wire, and you need more heavy gauge wire. Need to clean it up yet, but here are the guts. View attachment ImageUploadedByHome Brew1477159383.368051.jpg

And the final product. View attachment ImageUploadedByHome Brew1477159415.552133.jpg

Started out with a combine. This model was used for many years on the family farm. Every summer I would help my Dad get it ready for harvest. Lots of good memories associated with the IH 1482.

View attachment ImageUploadedByHome Brew1477159442.771127.jpg

Then I got a metal worker friend to turn it into a box. And started cutting holes.

View attachment ImageUploadedByHome Brew1477159487.077557.jpgView attachment ImageUploadedByHome Brew1477159499.425736.jpgView attachment ImageUploadedByHome Brew1477159511.063729.jpg

I ended up with kind of a reverse of most panels, with the door on the back. This does make it a bit of a pain to wire, and you need more heavy gauge wire. Need to clean it up yet, but here are the guts. View attachment ImageUploadedByHome Brew1477159383.368051.jpg

And the final product. View attachment ImageUploadedByHome Brew1477159415.552133.jpg