Sublime8365

Well-Known Member

I'm building a simple HERMS system and could use some help on wiring up my PID/SSR/element.

The plan is to pump the wort from my cooler/MT through what was previously an immersion chiller that will be placed in my HLT that has a 2000w heating element (I don't have a 240v power source so 120v/20A is what I'm going with).

I am not planning to use any switches or control the pump through this diagram unless someone makes the case for doing so. So the pump will be plugged in and powered separately and will run continously throughout the mash.

I have:

2000w heating element

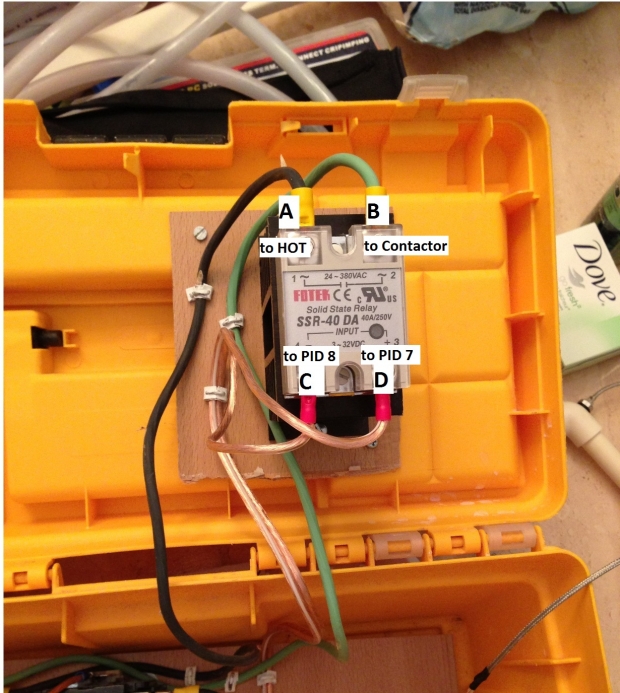

Auber SYL-2352 PID

40A/250V SSR-40 DA with heat sink

K-type thermocouple (I know I can use an RTD but I already had the k-type and thought I'd try to make it work)

Since I'm using a 120v power source I was going to plug the system into a surge protector and just use the switch on that to turn the power on/off at the beginning/end of the mash.

Can someone help me out here?

The plan is to pump the wort from my cooler/MT through what was previously an immersion chiller that will be placed in my HLT that has a 2000w heating element (I don't have a 240v power source so 120v/20A is what I'm going with).

I am not planning to use any switches or control the pump through this diagram unless someone makes the case for doing so. So the pump will be plugged in and powered separately and will run continously throughout the mash.

I have:

2000w heating element

Auber SYL-2352 PID

40A/250V SSR-40 DA with heat sink

K-type thermocouple (I know I can use an RTD but I already had the k-type and thought I'd try to make it work)

Since I'm using a 120v power source I was going to plug the system into a surge protector and just use the switch on that to turn the power on/off at the beginning/end of the mash.

Can someone help me out here?