I'm nearing the completion of the my small scale electric system - so thought I would share with those that have inspired this creation.

I have to re-build the electric enclosure (SSR too hot for smallest version) this weekend, perhaps get to brew sunday??!! Pictures forthcoming....

Ideas, comments?

I have a question:

1) Where do I get an inline fuse for this system??

TinyBrew (TB)

Concept:

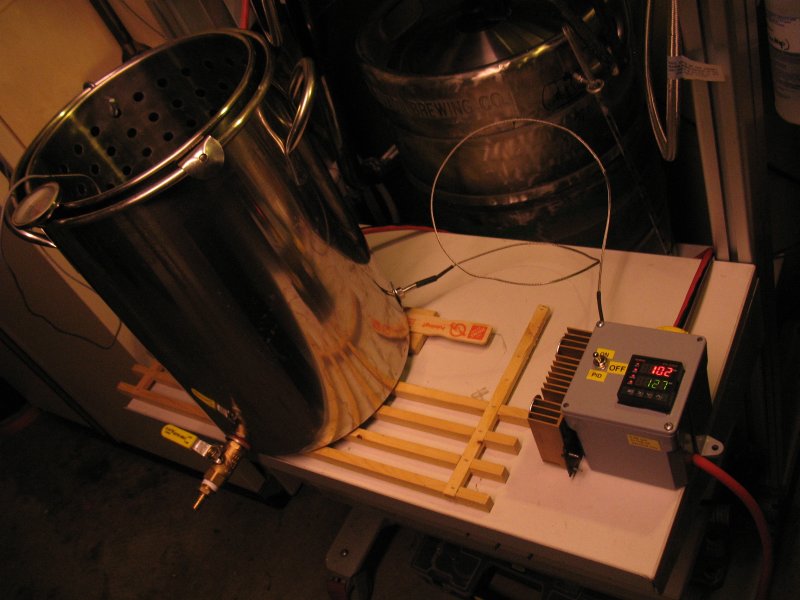

All-grain small batch (pilot type - 2 gal, bottled) PID controlled electric water heater element, no sparge, no chill (all the aussies are doing it this way!) for under $200.... did I mention stainless was requirement?

Proposed brewing process:

Heat full boil volume in pot to mash temp (dough in) - pour off sparge water into cooler - heat to sparge with heatstick. Place milled grain in nylon paint bag - into stainless fryer bucket, and into pot - (held in suspension with "S" hooks for handles). Steep. Remove Basket - Place into 'Sparge'. Stir. Steep. Remove basket/Discard Grain. Combine volumes. Boil/add hops.

That's the mash and boil - the no chill is pretty cool -

get a $7 container (for food shipping: http://www.usplastic.com/catalog/item.aspx?itemid=35995&catid=459&clickid=searchresults - or search "2.5 gallon natural") - these are apparently what they call - hot fill I think (they can be heat sanitized)

allow wort to cool to 190F - stir like mad to aerate (or use oxygen infuser) drain off into container. Squeeze out air. Seal and cool to room temp. Starter - stir. Pitch. add airlock. Add vodka - russian of course. Ferment til OG.

Oh yeah then drink

Actual build report:

I gathered alot of parts -

stainless pot ($59 - kitchenfantasy.com - 26QT tall, includes stainless basket, requires dremel modding to remove basket handle. It's fun. Bottom is too thin for gas fired/moving it around alot, but for stationary electric, perfect - if I did it again - apply "buy once" theory, get heftier pot.)

electric water heater ($9 - Home Depot - 2000W/120V - wish I had 240 available)

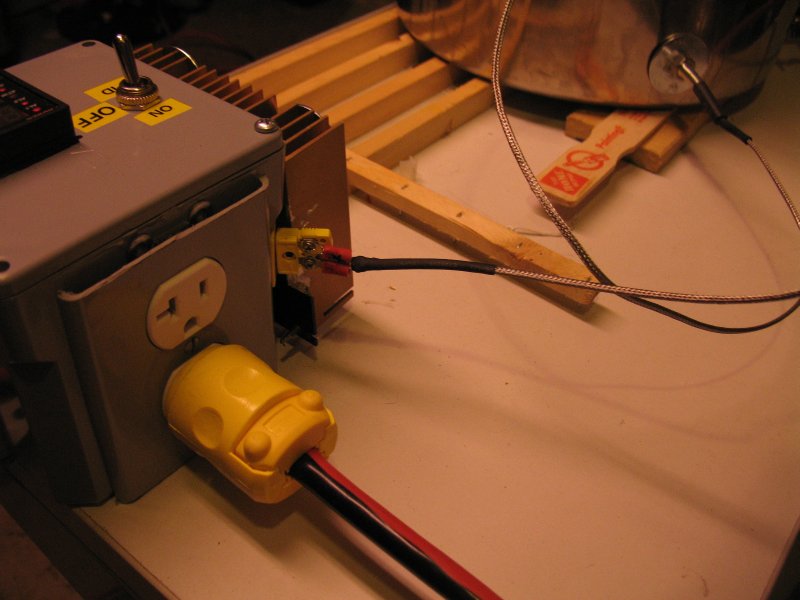

12GA Electrical extension cord ($20 - HD)

SSR ($10 - Ebay)

PID + Watertight Thermo ($65 - Auber)

Enclosure ($9 - Home Depot)

GFCI ($13 - Home Depot)

Weldless Fittings ($65 - bargainfittings.com )

No.

I did not make it within budget = $255.

It works :rockin:

I drilled the pot using step-bit for smaller holes and a holesaw for the element. I now owned a pot I intentionally poked four holes in:

1) 1.25" for heater element (holesaw)

2) 7/8" for ball valve

3) 1/4" NPT clearance for thermometer - I used the step bit until it fit, don't remember dimension.

4) Small 1/4" bit hole for ground connection.

Yes.

It leaked after assembly, most of the weldless fittings ( www.bargainfittings.com -- they are great )needed to be tighter than I thought they should. The ground hole was the major pain - could not figure out how to seal it and allow contact with wall material of pot. Never did figure this out. Turns out -- water is a great conductor, and its touching the whole pot Bonus.

Bonus.

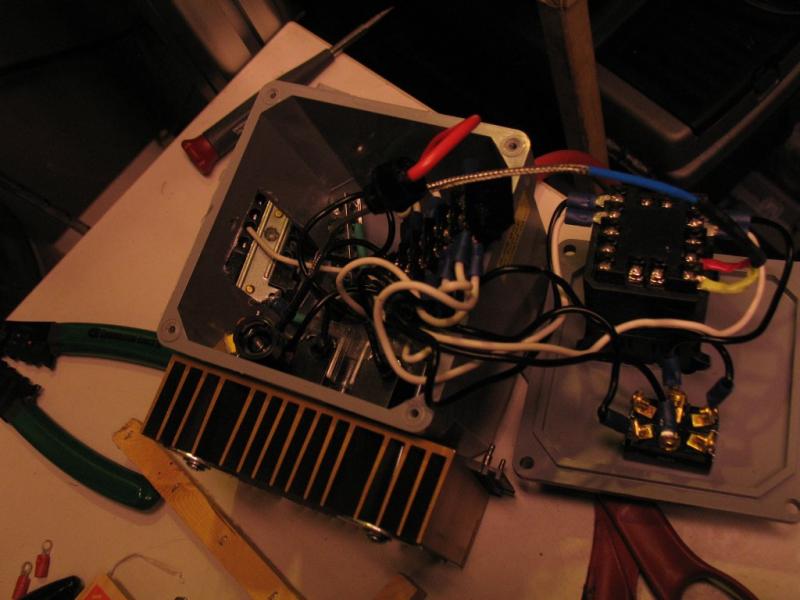

I originally wanted to cram everything into the smallest enclosure I could manage physically (it fit and worked) - after the first water heating ramp - I shut it down and was working on cleaning up the wiring - dam SSR was hot! I guess the larger Amp draw you pull, the more heat the SSR takes on - empirical knowledge. Needs bigger enclosure to run for a couple hours straight - create heatsink, check..

This is where I currently am - hope to brew this weekend!

Pliny the Elder Clone anyone? (https://www.homebrewtalk.com/f36/pliny-elder-recipe-questions-125517/)

Scale to rig....

I have to re-build the electric enclosure (SSR too hot for smallest version) this weekend, perhaps get to brew sunday??!! Pictures forthcoming....

Ideas, comments?

I have a question:

1) Where do I get an inline fuse for this system??

TinyBrew (TB)

Concept:

All-grain small batch (pilot type - 2 gal, bottled) PID controlled electric water heater element, no sparge, no chill (all the aussies are doing it this way!) for under $200.... did I mention stainless was requirement?

Proposed brewing process:

Heat full boil volume in pot to mash temp (dough in) - pour off sparge water into cooler - heat to sparge with heatstick. Place milled grain in nylon paint bag - into stainless fryer bucket, and into pot - (held in suspension with "S" hooks for handles). Steep. Remove Basket - Place into 'Sparge'. Stir. Steep. Remove basket/Discard Grain. Combine volumes. Boil/add hops.

That's the mash and boil - the no chill is pretty cool -

get a $7 container (for food shipping: http://www.usplastic.com/catalog/item.aspx?itemid=35995&catid=459&clickid=searchresults - or search "2.5 gallon natural") - these are apparently what they call - hot fill I think (they can be heat sanitized)

allow wort to cool to 190F - stir like mad to aerate (or use oxygen infuser) drain off into container. Squeeze out air. Seal and cool to room temp. Starter - stir. Pitch. add airlock. Add vodka - russian of course. Ferment til OG.

Oh yeah then drink

Actual build report:

I gathered alot of parts -

stainless pot ($59 - kitchenfantasy.com - 26QT tall, includes stainless basket, requires dremel modding to remove basket handle. It's fun. Bottom is too thin for gas fired/moving it around alot, but for stationary electric, perfect - if I did it again - apply "buy once" theory, get heftier pot.)

electric water heater ($9 - Home Depot - 2000W/120V - wish I had 240 available)

12GA Electrical extension cord ($20 - HD)

SSR ($10 - Ebay)

PID + Watertight Thermo ($65 - Auber)

Enclosure ($9 - Home Depot)

GFCI ($13 - Home Depot)

Weldless Fittings ($65 - bargainfittings.com )

No.

I did not make it within budget = $255.

It works :rockin:

I drilled the pot using step-bit for smaller holes and a holesaw for the element. I now owned a pot I intentionally poked four holes in:

1) 1.25" for heater element (holesaw)

2) 7/8" for ball valve

3) 1/4" NPT clearance for thermometer - I used the step bit until it fit, don't remember dimension.

4) Small 1/4" bit hole for ground connection.

Yes.

It leaked after assembly, most of the weldless fittings ( www.bargainfittings.com -- they are great )needed to be tighter than I thought they should. The ground hole was the major pain - could not figure out how to seal it and allow contact with wall material of pot. Never did figure this out. Turns out -- water is a great conductor, and its touching the whole pot

I originally wanted to cram everything into the smallest enclosure I could manage physically (it fit and worked) - after the first water heating ramp - I shut it down and was working on cleaning up the wiring - dam SSR was hot! I guess the larger Amp draw you pull, the more heat the SSR takes on - empirical knowledge. Needs bigger enclosure to run for a couple hours straight - create heatsink, check..

This is where I currently am - hope to brew this weekend!

Pliny the Elder Clone anyone? (https://www.homebrewtalk.com/f36/pliny-elder-recipe-questions-125517/)

Scale to rig....