Holter

Well-Known Member

Ive been documenting my build over on the forums at Kal's electric brewery site but I figured that I should post it over here. Like so many others, I browse HBT because it is such a great resource. I figure I should post pics of my setup for others to look at as well.

Going into this i knew very liittle about electricity, in fact i still dont. Because of that i really tried to focus on copying Kal's writeup as much as possible. Since there are so many people cloning Kal's panel I will skip that portion and just focus on the kettles, plumbing and brew stand.

Instead of building the wood stand that Kal built I went with this stand from Home Depot - http://www.homedepot.com/buy/storag...idth-x-24-in-depth-x-78-in-height-145323.html. The main reason was just look. We wanted a metal stand with some wood, but not all wood.

It's capacity seemed right for a single tier system, and the price was good. The downside to this stand out of the box was that it had metal shelves and we wanted wood.

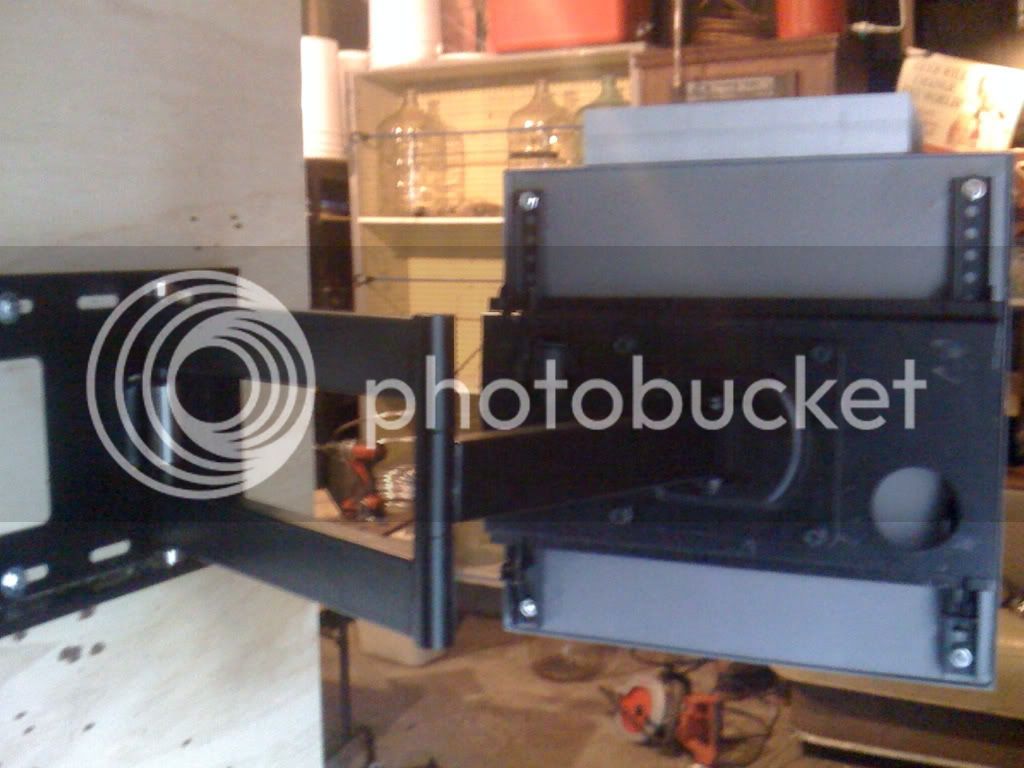

Here is a picture of the stand with a piece of plywood in place of the metal shelves that came with it (you can see the metal shelves in the background leaning up against the kegerator).

Going into this i knew very liittle about electricity, in fact i still dont. Because of that i really tried to focus on copying Kal's writeup as much as possible. Since there are so many people cloning Kal's panel I will skip that portion and just focus on the kettles, plumbing and brew stand.

Instead of building the wood stand that Kal built I went with this stand from Home Depot - http://www.homedepot.com/buy/storag...idth-x-24-in-depth-x-78-in-height-145323.html. The main reason was just look. We wanted a metal stand with some wood, but not all wood.

It's capacity seemed right for a single tier system, and the price was good. The downside to this stand out of the box was that it had metal shelves and we wanted wood.

Here is a picture of the stand with a piece of plywood in place of the metal shelves that came with it (you can see the metal shelves in the background leaning up against the kegerator).