junkyard brewer

Well-Known Member

Good things come to those who wait. Kids, family and things that make them happy should always take priority.

Keep up the hard work!

Keep up the hard work!

Had a couple of hours today to build the pump and plate chiller mounting system. Of course, I had to incorporate knotty pine boards and cedar logs. Hard to tell by the pics, but should look decent once clear coated. I just need to order a couple of more cam lock fittings for the plate chiller and run the duct work for the ventilation fan. Almost there!

Thanks TD! My kids go to Oxford Schools....great school system and a great place to live. Close to everything, but still some seclusion if you want it.

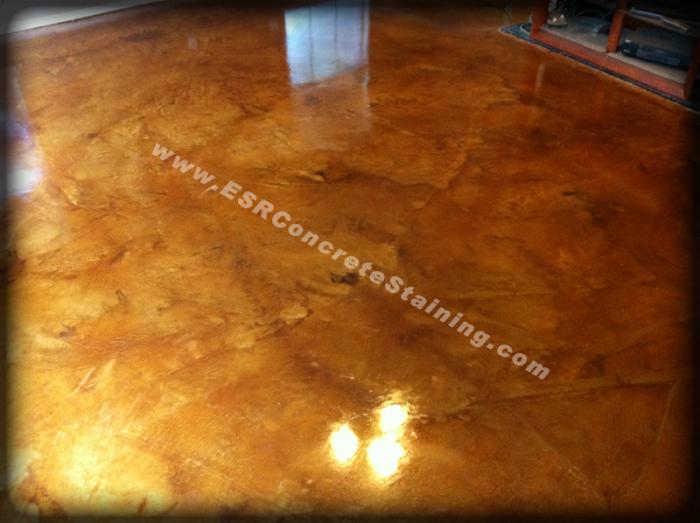

Had a busy day in the brewery yesterday. I spend several hours emptying the room and moving all of the components over to my exercise room. I built a cedar framed, knotty pine paneled door to hide the plumbing under the sink. I wiped down all of the wood work and walls and am ready to finish off the rest of the wood work clear coating. I then plan on priming, then painting the floor with a heavy duty epoxy floor paint, as I don't feel like doing any more tiling at this point. Once that is done, I will run the vent out the back of the house and finish grouting all of the components.

I finally fired up the panel to check out the BCS platform last night via the internal wifi adapter. I was having problems accessing the ebrewsupply network from my IPad, so I sent and email to Ryan @ ebrewsupply. He responded almost immediately with his cell phone number and walked me through the logging on process. I'm a bit of an IT idiot. He was also nice enough pre-load his typical brewing process into the BCS, which will save me a ton of time. His process is slightly different than mine, but it will be much quicker tweaking his processes than having to start from scratch! It is still going to take some time learning the programming, but he gave me a great head start. I can't thank Ryan enough for the quality of his panels and his friendly customer support!

Thanks. Yeah, we had a garage sale a few years back and sold several old VCR's and a boat load of outdated electronics. I didn't feel like carrying the tube TV's up though. I have a 36" panasonic that probably weighs close to 100 lbs. I put the smallest of the 3 on the shelf, because the other two would stick out way too far, as they are easily 25" deep.....my how technology has changed. I have a 55" LED that is 1" thick. I took a few measurements last night and the shelf would accommodate a 42" flat panel, but it would be right up to the drop ceiling line once installed. I'll probably go with a 32" for clearance, as the room isn't too terribly large. Time to take a trip to Goodwill and unload the other boat anchors.

Are those HopSlam mini-kegs?

Not sure I've seen them before. That could be dangerous...

I haven't seen the mini kegs since, but did get my hands on a couple of 6 packs this year.

I haven't seen the mini kegs since, but did get my hands on a couple of 6 packs this year. This is an incredible build (and home brewery). Thanks for documenting it and your other projects!

A friend and I finished a large bar that he and his brother built in NH. Local pine slabs, live edge, sealed with a clear epoxy coat. Beautiful, as is your work. Get brewing.

Oops, forgot to attach the pic.

Enter your email address to join: