The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 117

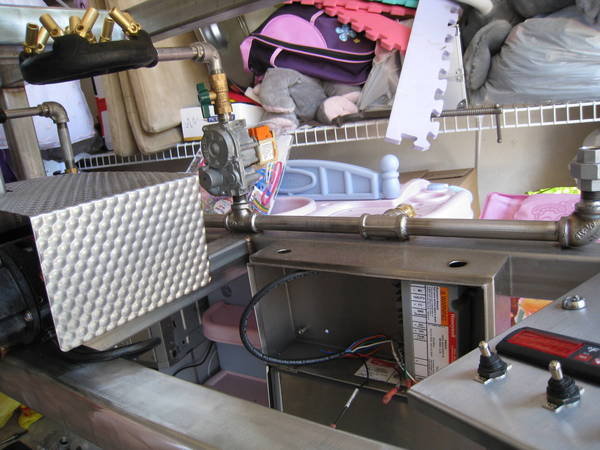

I plan to use polished keggles... or something of the like. Really, Blichmans are so outrageously expensive. I suppose that I can see where I am at $$ wise when I get the frame and mechanical portions completed, kettles will be last.