Uncle Argyle

Well-Known Member

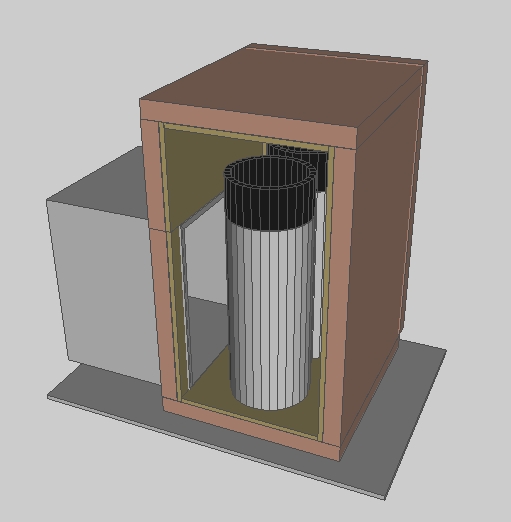

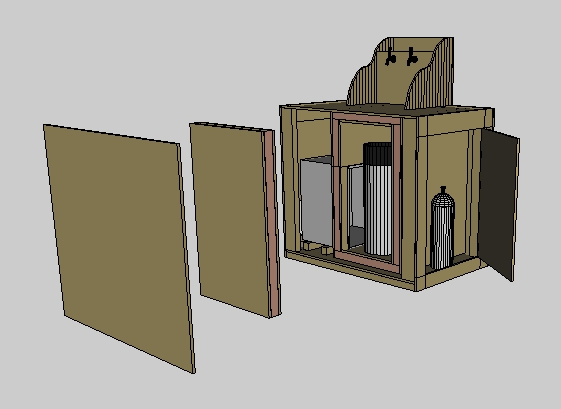

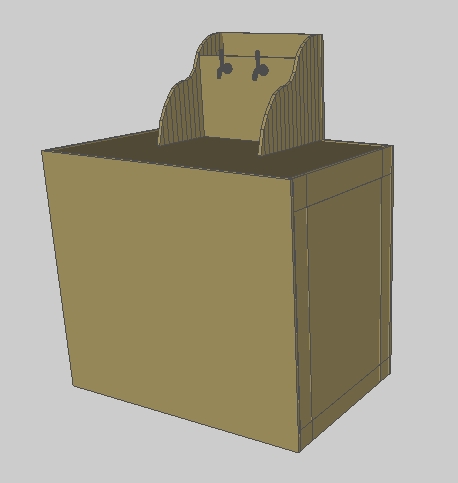

I was reading a project that Dude had posted (https://www.homebrewtalk.com/showthread.php?t=14907&page=4) and thought about making a mini cold box...basically using a 1.7 cu ft. dorm fridge. The storage are would be just big enough to house 2 cornies (CO2 would be outside).

My question is...would this fridge this small be strong enough to bring 2 cornies down to the correct temprature?

Thanks,

Mike.

My question is...would this fridge this small be strong enough to bring 2 cornies down to the correct temprature?

Thanks,

Mike.