HossTheGreat

Well-Known Member

- Joined

- Mar 28, 2009

- Messages

- 523

- Reaction score

- 5

***3/6/2011 UPDATE*** The rig has been finished and the maiden voyage completed. Updated with lots of pics below.

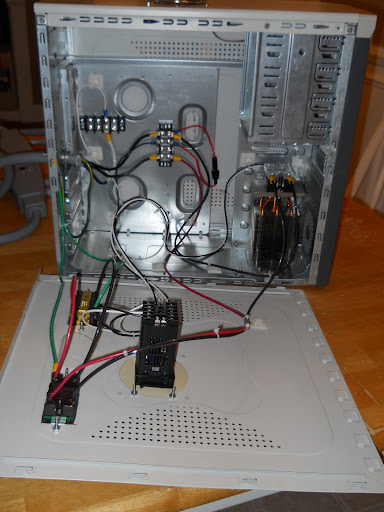

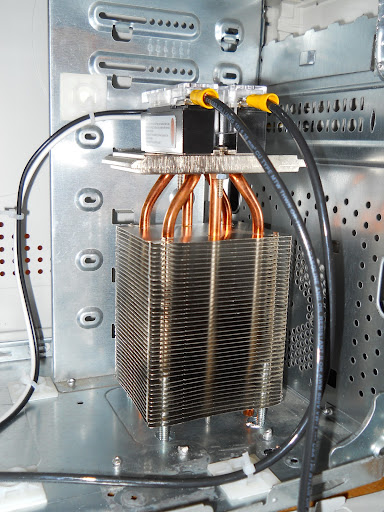

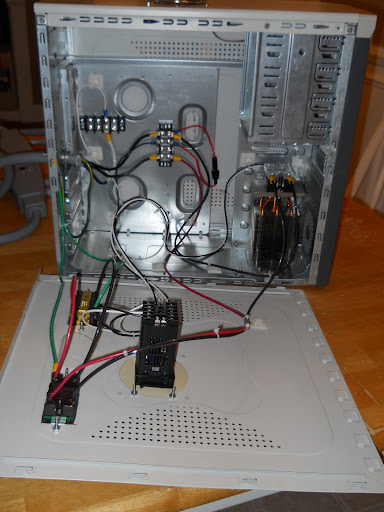

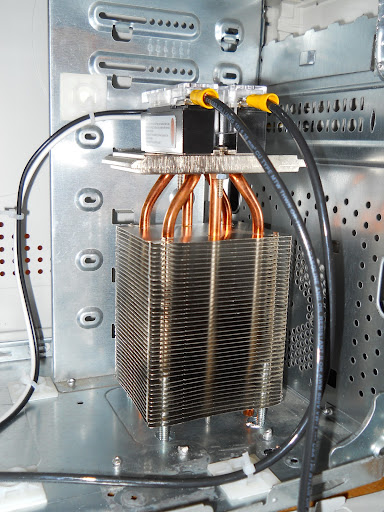

Here's a few pictures of the new control panel that I am almost finished wiring up. I put an old computer case that I had laying around to good use. It's a pretty simple setup, since I do a single vessel BIAB.

I do have one question about the SSR. You can see that the heatsink is enclosed in the case. I know that many people who use small water-tight enclosures opt to put their heatsink on the outside of the box. Do you think I'll run into any heat issues with the current setup? Obviously I do have the option of running a couple of case fans, but this would require me to purchase a transformer to step the voltage down, plus an ac to dc transformer to feed the fans. Just curious if this is necessary, or if I should be ok.

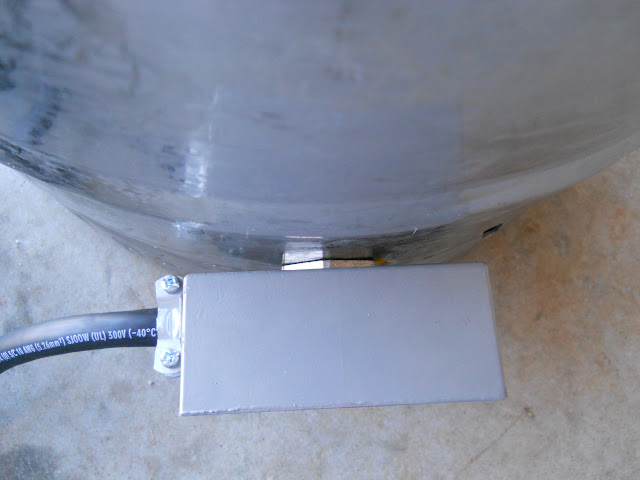

Next, here's a look at the outside. Before anyone says anything, I know there's no point in having waterproof covers, but I wanted a cover for the outlet just for a little added safety....and I just thought the switch cover was pretty cool.

Here's a few pictures of the new control panel that I am almost finished wiring up. I put an old computer case that I had laying around to good use. It's a pretty simple setup, since I do a single vessel BIAB.

I do have one question about the SSR. You can see that the heatsink is enclosed in the case. I know that many people who use small water-tight enclosures opt to put their heatsink on the outside of the box. Do you think I'll run into any heat issues with the current setup? Obviously I do have the option of running a couple of case fans, but this would require me to purchase a transformer to step the voltage down, plus an ac to dc transformer to feed the fans. Just curious if this is necessary, or if I should be ok.

Next, here's a look at the outside. Before anyone says anything, I know there's no point in having waterproof covers, but I wanted a cover for the outlet just for a little added safety....and I just thought the switch cover was pretty cool.