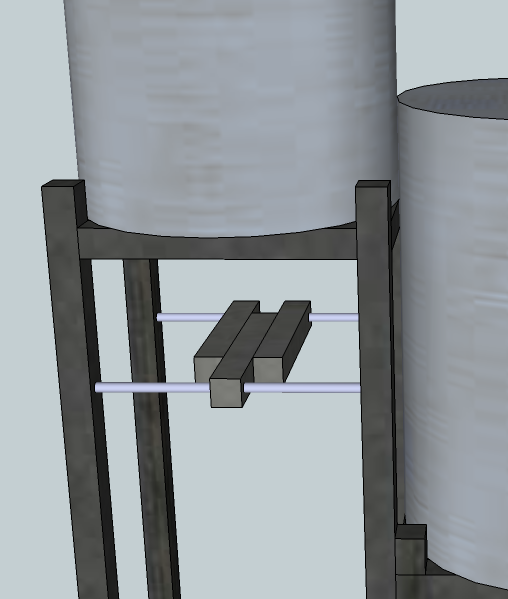

Hello hello. I will start to build a brew stand in the next 2 weeks or so, and have came up with the following design:

I have never seen any designs which are aligned 'diagonally' like this. I wanted to come up with a design where I could fit my keggles in between 4 corner posts such that they would be somewhat secure.

My questions:

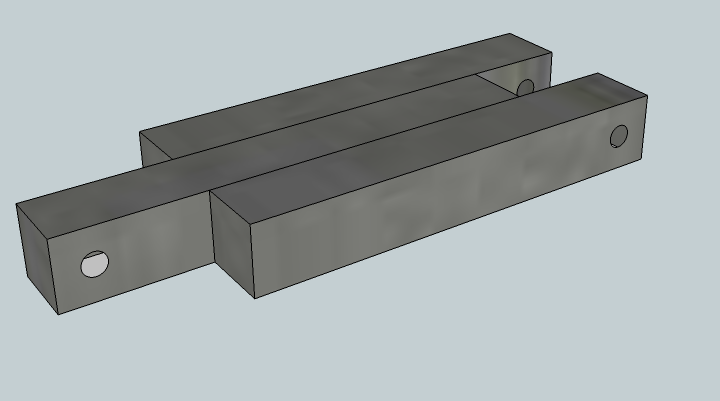

Does this design look unstable or weak? I figure I could build it, and easily add reinforcement if it were. I am also considering adding a basic platform which would allow me to step up to manage my HLT, which could increase stability if necessary. This design uses 1.5" square steel. What gauge do you think I could get away with?

Secondly, if the height, thus materials could be reduced, that would be nice. This also would increase stability. I am wondering how much height is required between tiers to produce adequate siphon action/flow rates. This system will be used to do 10 gallon batches. I should've went out to the garage to measure my kegs, but I just figured they were 16 1/8th" in diameter and 23 3/8" in height as I found somewhere on the web, for the purpose of drawing out my idea.

I also plan to reduce the entire overall height when my burner arrives and I can see better what I am working with/how much clearance from the ground I can get away with on the lowest tier. I am going to try to use just one burner, which is movable between the tiers. It'll be connected (after a length of pipe) to a flexible hose. I was having trouble finding a natural gas burner in Ontario for a reasonable price, and combined shipping rates for ordering multiple burners from the states were not good enough for me to go out and buy 2 or 3 at the same time (and I am trying to keep costs down!)

Anyways! I appreciate any of your advice. I am sort of head in the clouds type and come up with these ideas which are not always the greatest, lol. At least I tend to structure my ideas such that they are flexible!

I have never seen any designs which are aligned 'diagonally' like this. I wanted to come up with a design where I could fit my keggles in between 4 corner posts such that they would be somewhat secure.

My questions:

Does this design look unstable or weak? I figure I could build it, and easily add reinforcement if it were. I am also considering adding a basic platform which would allow me to step up to manage my HLT, which could increase stability if necessary. This design uses 1.5" square steel. What gauge do you think I could get away with?

Secondly, if the height, thus materials could be reduced, that would be nice. This also would increase stability. I am wondering how much height is required between tiers to produce adequate siphon action/flow rates. This system will be used to do 10 gallon batches. I should've went out to the garage to measure my kegs, but I just figured they were 16 1/8th" in diameter and 23 3/8" in height as I found somewhere on the web, for the purpose of drawing out my idea.

I also plan to reduce the entire overall height when my burner arrives and I can see better what I am working with/how much clearance from the ground I can get away with on the lowest tier. I am going to try to use just one burner, which is movable between the tiers. It'll be connected (after a length of pipe) to a flexible hose. I was having trouble finding a natural gas burner in Ontario for a reasonable price, and combined shipping rates for ordering multiple burners from the states were not good enough for me to go out and buy 2 or 3 at the same time (and I am trying to keep costs down!)

Anyways! I appreciate any of your advice. I am sort of head in the clouds type and come up with these ideas which are not always the greatest, lol. At least I tend to structure my ideas such that they are flexible!