Hey all, I'm planning on building a new brutus system, and I need some pointers. So far I plan on pretty much replicating Kal's "The Electric Brewery" system, except I will be using gas for now, and this will obviously be a manual system.

I plan to start things out by building a weldless brew stand, as seen here.

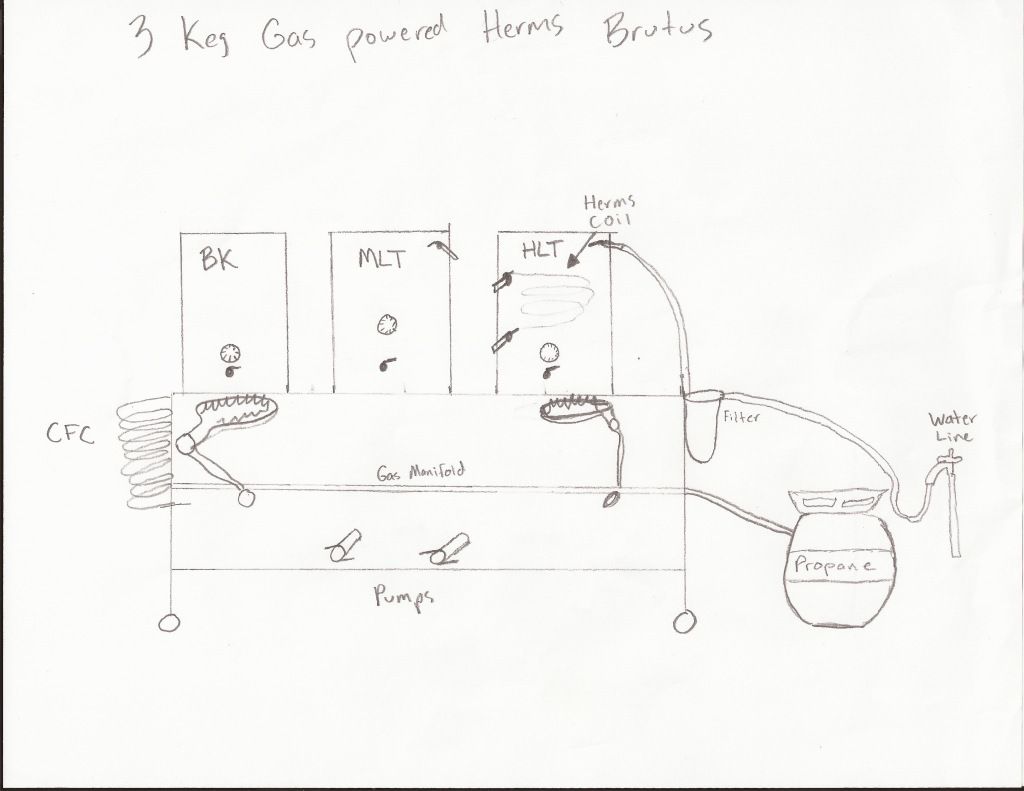

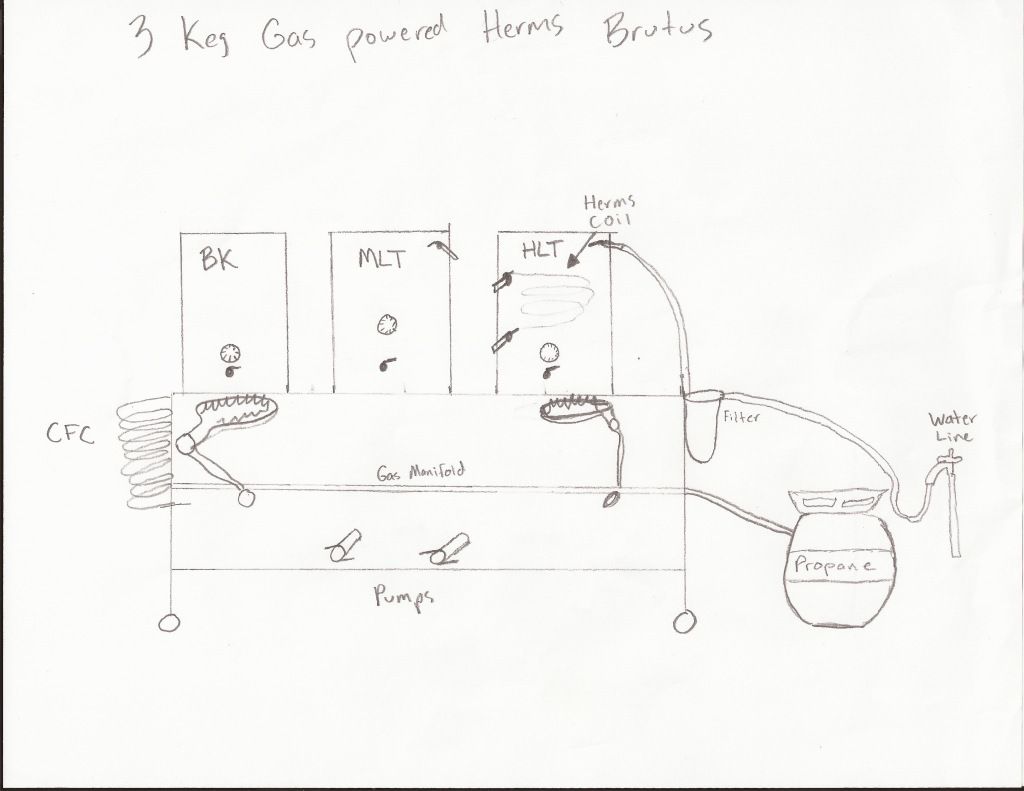

Here is a poorly drawn layout of what I plan to do:

At the moment I currently have nothing; simply cash and: A keg converted brew kettle, and a 10 gallon igloo mash tun (which i will probably sell). So I will essentially build this system from scratch.

I plan on using 100% quick disconnects on all my ball valves. The ones Kal used in his system look real shiny, pretty, and quicker than the cam lock disconnects with the 2 little clips that bobby and AHS sell.

Some side notes are that the MLT will feature a false bottom, and the keg will have a hop stopper. Also, I forgot to draw sight glasses on the HLT and BK. I'm still on the fence about installing a sight glass on the MLT. The pumps will be those chugger pumps bobby sells on his site that have the stainless center inlet.

My main concerns with this build at the moment are:

1. During the doughing in process, won't the keg walls (MLT) absorb a lot of the heat and cause the mash to drop in temp? I know the HERMS process is supposed to fix that, but will I have to keep turning on/off the HLT burner every 2 minutes or so? How well do kegs maintain their temperature?

2. To anyone that has a system similar to mine, how much detail do i have to pay to maintaining HLT temps during the mash. I understand i am building a manual system, but how difficult is it to maintain accurate temps so that the mash has a good consistent temp? In other words, do i need to be starring at the thermometers throughout my 60-90min mashes, or will i have the luxury to sit back and have a homebrew and check on it every 10 mins or so?

3. I don't know if installing a burner on the MLT is necessary at all. I currently have 2 propane tanks, and i think i can just hook them up individually, to each burner. This way I won't have to install the gas manifold i drew up (mostly because i don't know how :cross

This brutus is just a temporary build. I plan on building a brew shed within the year, and switching to all electric. But for now, I need to build something that can help me brew ASAP. If anyone has ever built a gas powered HERMS system, please provide me with any input on my 3 concerns, ideas, feedback, comments, criticism, opinions or anything you feel i may be overlooking. Thanks a bunch!!

-Alex

I plan to start things out by building a weldless brew stand, as seen here.

Here is a poorly drawn layout of what I plan to do:

At the moment I currently have nothing; simply cash and: A keg converted brew kettle, and a 10 gallon igloo mash tun (which i will probably sell). So I will essentially build this system from scratch.

I plan on using 100% quick disconnects on all my ball valves. The ones Kal used in his system look real shiny, pretty, and quicker than the cam lock disconnects with the 2 little clips that bobby and AHS sell.

Some side notes are that the MLT will feature a false bottom, and the keg will have a hop stopper. Also, I forgot to draw sight glasses on the HLT and BK. I'm still on the fence about installing a sight glass on the MLT. The pumps will be those chugger pumps bobby sells on his site that have the stainless center inlet.

My main concerns with this build at the moment are:

1. During the doughing in process, won't the keg walls (MLT) absorb a lot of the heat and cause the mash to drop in temp? I know the HERMS process is supposed to fix that, but will I have to keep turning on/off the HLT burner every 2 minutes or so? How well do kegs maintain their temperature?

2. To anyone that has a system similar to mine, how much detail do i have to pay to maintaining HLT temps during the mash. I understand i am building a manual system, but how difficult is it to maintain accurate temps so that the mash has a good consistent temp? In other words, do i need to be starring at the thermometers throughout my 60-90min mashes, or will i have the luxury to sit back and have a homebrew and check on it every 10 mins or so?

3. I don't know if installing a burner on the MLT is necessary at all. I currently have 2 propane tanks, and i think i can just hook them up individually, to each burner. This way I won't have to install the gas manifold i drew up (mostly because i don't know how :cross

This brutus is just a temporary build. I plan on building a brew shed within the year, and switching to all electric. But for now, I need to build something that can help me brew ASAP. If anyone has ever built a gas powered HERMS system, please provide me with any input on my 3 concerns, ideas, feedback, comments, criticism, opinions or anything you feel i may be overlooking. Thanks a bunch!!

-Alex