DrivewayBeer

Active Member

- Joined

- Jul 31, 2011

- Messages

- 28

- Reaction score

- 0

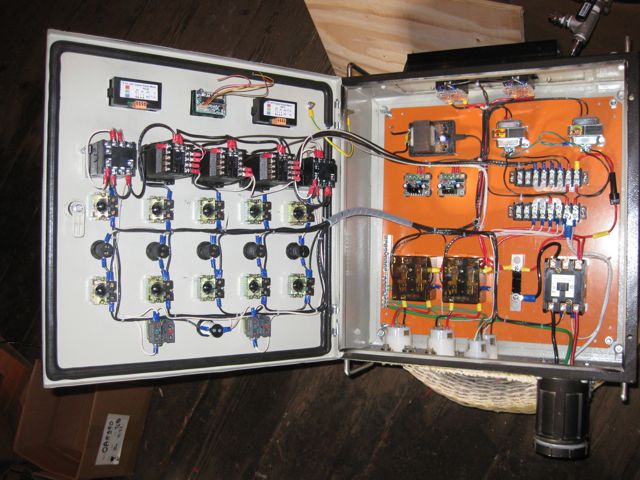

I have the equipment to brew two 10 gallon batches at the same time. Each set up is 3 keggles. Currently I use propane burners but would like to add some heating elements and build a control box.

Currently, I am in the process of building a control box and adding heating elements to the HLT and the Boilers. I plan on having 4 PIDs all in one control box. I bought a 50 Amp Spa panel and plan on running about 75 feet of cable to my set up on the drive way.

I have a couple of questions. Can I power 2 5500W elements at the same time from one 220V power source after the 50A spa panal? Should have I bought the 60A? 2 March pumps would be running the circulation.

Also is it better to put the spa panel next to the dryer and run the 75 foot cable to the control box. Or put the sap panel nearer to the control box. Cheers

Currently, I am in the process of building a control box and adding heating elements to the HLT and the Boilers. I plan on having 4 PIDs all in one control box. I bought a 50 Amp Spa panel and plan on running about 75 feet of cable to my set up on the drive way.

I have a couple of questions. Can I power 2 5500W elements at the same time from one 220V power source after the 50A spa panal? Should have I bought the 60A? 2 March pumps would be running the circulation.

Also is it better to put the spa panel next to the dryer and run the 75 foot cable to the control box. Or put the sap panel nearer to the control box. Cheers