Hey guys,

Very new to brewing, just moved to a larger apartment in Manhattan where I can finally do some brewing!

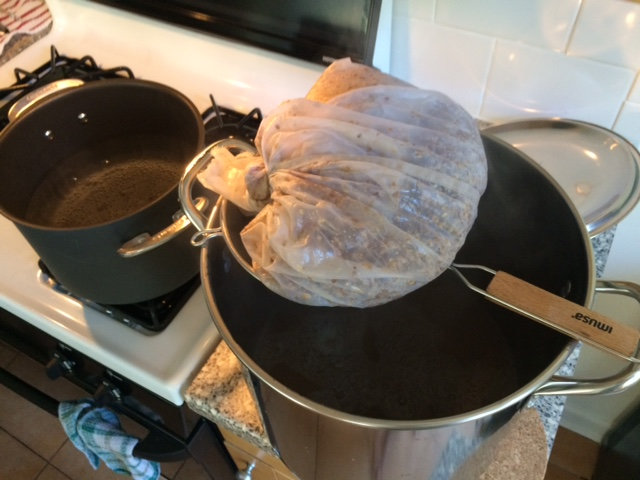

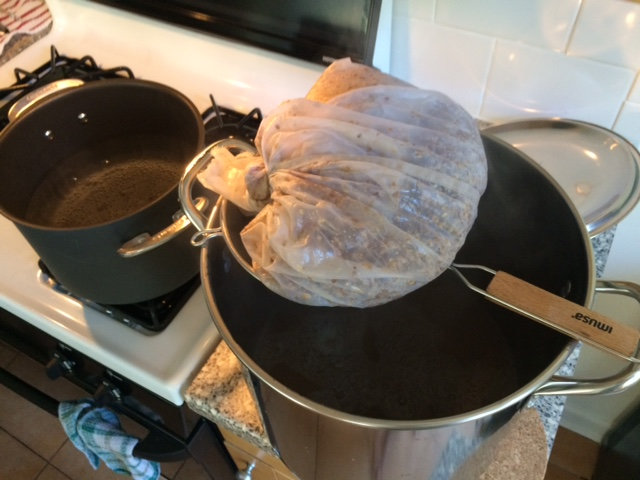

First attempt doing a 1 gallon all grain American IPA (on 7/4)

-1.20 kg of American 2 row

-150 g of Crystal caramel 40

-60 minutes .3oz Centennial

-20 minutes .3oz Cascade

-0 minutes .3oz Cascade

-1/2 vial of White Labs california ale yeast without a starter

I think it went well, it ended up having a 1.060 OG, tasted the wort seemed good. I put it in a plastic bucket fermenter. Was bubbling like crazy for 3 days then settled down yesterday.

My main concern are the temperature near the upper 80s right now which is not good for fermentation.

I think i'll take a sample this weekend. Is it possible to use the bucket spigot to take a sample during fermentation or is that only for bottling?

Here's a few pics... let me know what you think please

I'll probably have more questions along the way!

Thanks for reading

Very new to brewing, just moved to a larger apartment in Manhattan where I can finally do some brewing!

First attempt doing a 1 gallon all grain American IPA (on 7/4)

-1.20 kg of American 2 row

-150 g of Crystal caramel 40

-60 minutes .3oz Centennial

-20 minutes .3oz Cascade

-0 minutes .3oz Cascade

-1/2 vial of White Labs california ale yeast without a starter

I think it went well, it ended up having a 1.060 OG, tasted the wort seemed good. I put it in a plastic bucket fermenter. Was bubbling like crazy for 3 days then settled down yesterday.

My main concern are the temperature near the upper 80s right now which is not good for fermentation.

I think i'll take a sample this weekend. Is it possible to use the bucket spigot to take a sample during fermentation or is that only for bottling?

Here's a few pics... let me know what you think please

I'll probably have more questions along the way!

Thanks for reading