This afternoon, I got the Boil kettle put together! This was the simplest of the Kettles, so I figured that it made a good starting point to cutting into these fancy pots.

Here we go:

Marked off the 1/4 sections on the kettles using a fiberglass tape from the wifes collection of goodies. Started with a pilot hole to guide the large bit:

Then went to the large bit, for the Qmax punch bolt to pass through:

And finally, ran the punch through the kettle wall:

The finished punch-out for the boil element:

Then I started marking out the temperature probe, this one I piloted and then drilled with my Greenlee Step bit, as it was the only hole that required a 9/16" punch. I couldn't warrant buying the punch for just one hole, so I opted for the quick and dirty step bit.

Installing the element housing onto the kettle. I did leak test this before applying silicone sealant to the inside of the box, so you won't see the silicone applied in these pictures:

Element and Probe installed, read for the leak test:

Here's a major milestone, the first time I've fired the kettle!! Filling from the cold-water filter using one of the hoses I built earlier:

Setting up the Boil PID (note the EEEE on the other pids, which are not hooked up):

Bringing the cold water up to mash temperature which isn't really realistic in the boil kettle, but gave me a good test temperature to target:

Finally, drained the kettle to apply the silicone sealant to the face of the element to prevent rust, to the inside of the junction box to increase the safety factor and seal it up tight, and install the hop-stopper!

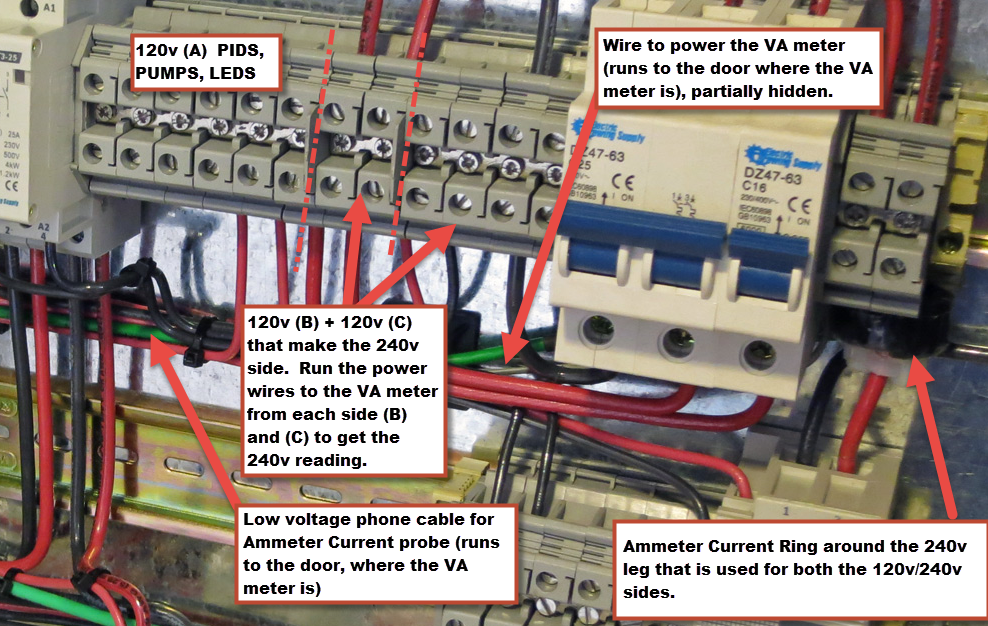

Tomorrow I'm headed to the HLT. Feels like we're close now, so far the panel has performed flawlessly. I see about 22.7a draw on my 245v line when the elements are firing (5500w) and the pumps work great, although I discovered I have a leak in my elbow joint that I need to attend to.

Stay tuned! :rockin: