Two questions:

What type of tool/ instrument should I use to cut into the center wall to place the fans?

What method are you using to hang/ mount the dual body regulator?

I am just looking to have two kegs on the serving side. I think that I now have all of the parts I need, the schematic, and I have completed all the initial tear out and prep work complete. Time to cut out the holes for the fans, wire it up, and make it look nice. Any suggestions would be great. These threads have been such a big help!!

I used a Dremel with a metal cutoff disc. I put the fan up to the panel where I wanted it and traced the outline, then cut on the lines. After the cutout was removed I cut out the insulation with a utility knife. If you cut this accurately your fan will fit tightly in the hole. I then fitted and placed the fan in the hole, and using a drill, I ran a small drill bit through the mounting holes on the fan to mark the other side of the panel. This side I cut out a smaller hole. Just enough to give an opening for the fan. This way I could fit the fan in the cutout, and run the mounting bolts from the smaller cutout side. Oh yeah, its easier to start this from the fridge side as there is more room to work.

Another thing, I use two fans, both installed with the same procedure, one high, one low, only they each blow in opposite directions, creating an effective circulation, and evening the temps on both sides. I use the entire fridge as a kegerator so I want it all the same temperature. One fan is wired to the main STC1000 with the temp probe on the fridge side and comes on with the compressor. The other fan is wired to a separate STC1000 with the probe on the freezer side and is attached to the heat relay. This way if the freezer side drops below the desired temp this fan will come on independent of the compressor and even up the temps.

I also use 110v fans that can be wired directly.

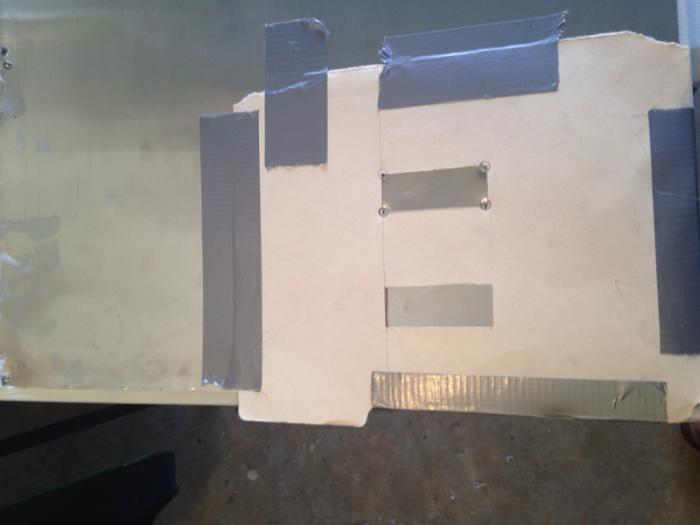

The STC 1000 can be installed in the door using the same Dremel cutoff wheel and procedure starting by marking the outside, cutting out the hole, removing insulation, and marking the inside hole with w drill bit from the outside. Cut as little as possible to create a tight fit, and a neat appearance.

First pic is of the installed fan.

The second is of the installed STC 1000.